KF-9080W Wet Sandblasting Machine, Wet Grit Blasting Machine

In the wet blasting process, abrasive media is mixed with water in a slurry pump. The pump deliver the mixture to the blasting gun while compressed air is to be the accelerate power.

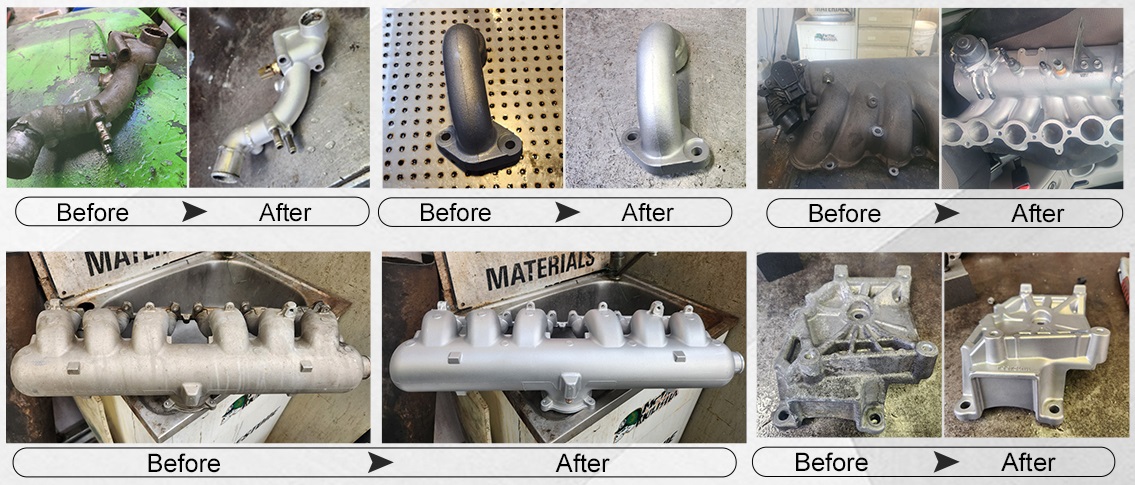

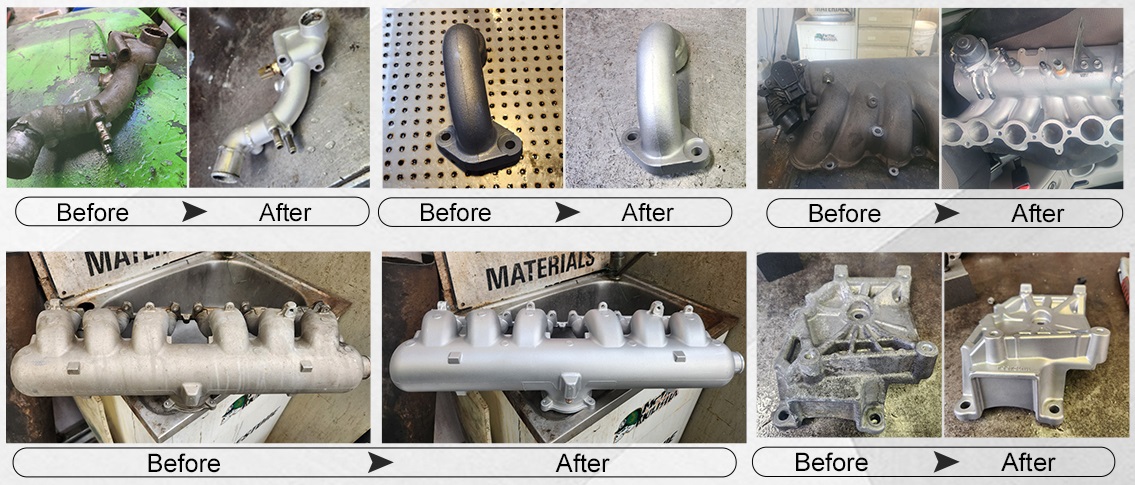

When it's used to clean a surface, the blasting grit eliminates the rust, oxides or unwanted coatings, at the same time the water washes them away. When it's used to finish a surface, the abrasive smooths down the surface and the water softens it blow.

Why choose wet sandblasting machines?

1. When doing removing process, the water is washing off the media impregnation and stripped materials. Thus you're doing the treatment and cleanup all in one go.

2. Decrease the friction heat generated during the blasting in order to prevent color change of workpieces.

3. Creayes more gentle surface removal, an ideal tool to finish precise or delicate workparts.

4. Wet slurry blasting will minimize the wear and damage caused to the abrasives and blasting machine.

Wet Sandblasting Machine Configurations & Features

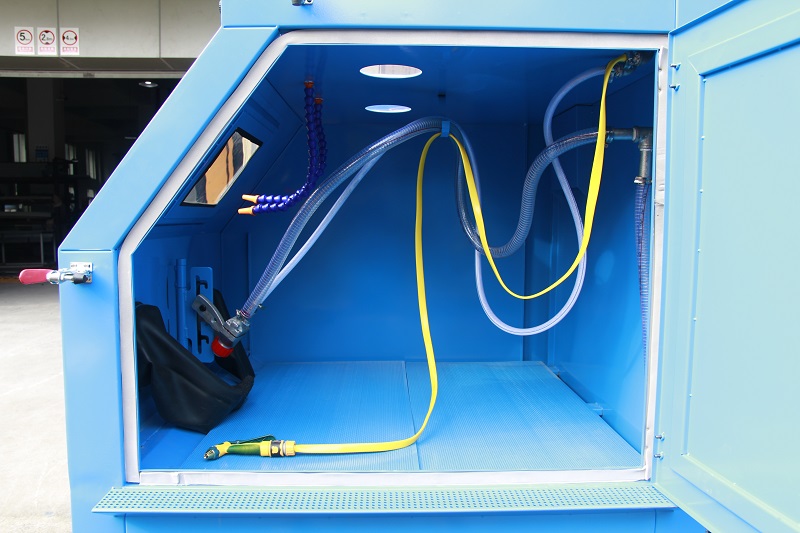

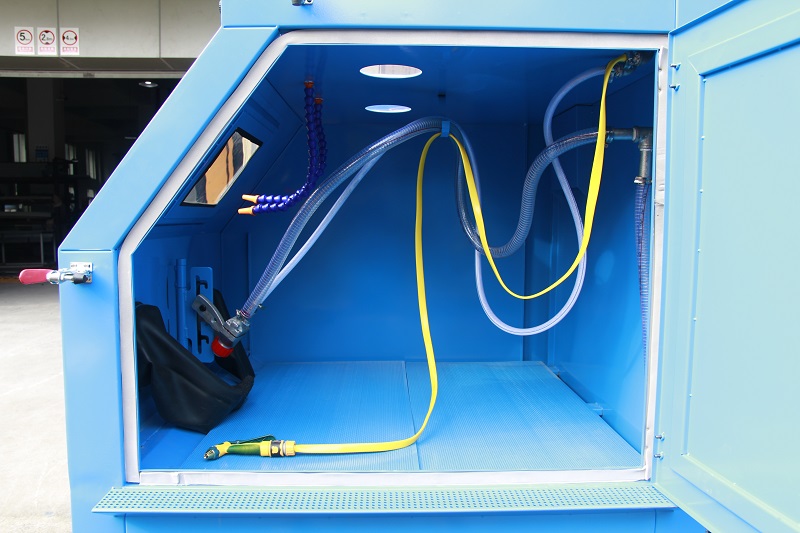

Stainless steel body, anti-rust. The working chamber is equipped with a rubber plate to prevent the jet impact.

The wet sandblast cabinet is equipped with a slurry pump delivering highest mixture of abrasive and water.

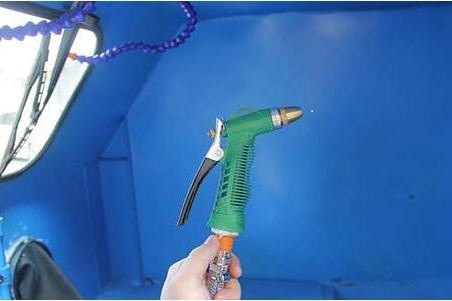

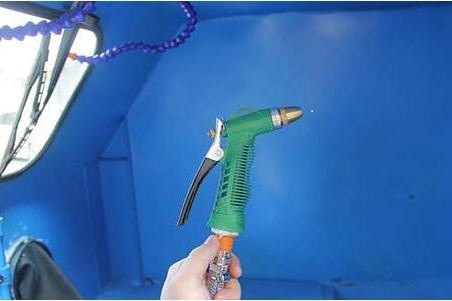

Rust resistant blast gun with durable boron carbide nozzle can be used for long time wet blasting.

Foot pedal controlled working of blasting gun ensures safe and reliable working.

The wet blasting cabinet has buit-in pressure regulating valve and gauge for easy operation.

There is screen washer installed in the glass window keeping a clear view during the wet blasting

Wet abrasive blast machine with compact and simple structure requires less maintenance.

An additional dust extractor ensures higher quality working conditions.

window washer

window washer

wet blast gun

water gun

demister

foot switch

KF-9080W Wet Sandblasting Machine Specifications

| Model | KF-9080W |

| Outer size | 1000*1200*2000mm |

| Working area | 900*900*800mm |

| Weigth | 280kgs |

| Loading | 30-50kgs |

| Motor | 2.2Kw |

| Air requirement | flow 0.5-1.1m^3/min |

| Light | 2*18w saving lamps |

| Blast Gun | 1 pc of wet blast gun with 1 boron cabide nozzle (8mm) |

| Air consumption for 1 gun | 0.4-0.8Mbar |

| Volume of abrasive & water | 25L |

| Suitable abrasive | Glass beads(for aluminum, stainless steel) Brown Aluminum Oxide(stell or other)80#-320# |

| Feed abrasive | 4-6kg |

| Abrasive : Water | 1:3 |

| Voltage | 380V/220V 3 phase (customized) |

Popular Standard Models of Wet Sandblasting Machine

| Model | KF-1212W | KF-1010W | KF-9080W | KF-6868W |

| Working size | 1200*1200*800mm | 1000*1000*800mm | 900*900*800mm | 600*600*500mm |

| Weight | 350kgs | 300kgs | 280kgs | 200kgs |

| Loading Capacity | 80-120kgs | 50-80kgs | 30-50kgs

| 20-30kgs

|

Wet Sandblasting Machine Application

Wet sandblasting machine is an innovative sandblasting equipment, a significant revolution in sandblasting industry, it was deeply welcomed and recognized by the users as soon as it came out. As the excellent feature of delicate finishing, it can be widely used for precise parts, such as aerospace, electronics, weapons industry, automation, optics and other instrumentation industries; machine tools, molds, hydraulic parts, hardware tools, cars, tractors, motorcycles, power machinery, train locomotives and other factories, textile machinery parts, medical equipment parts, chemical machinery, metal materials, artificial crystals, springs, metal processing industry, dental, jewelry, watches, clocks, glasses and other high precision requirement industries.