KF-1212W Wet Abrasive Blasting Cabinet for Sale

Wet blasting cabinet works by using a specially pump that agitates water and media into a slurry mixture and delivers it to the blast nozzle, while compressed air is introduced to accelerate the slurry and creates the cleaning effect.

Wet Abrasive Blasting Cabinet Advantages

1. Clean Process. As the flushing action of the water, three is no media impregnation into the parts, and features dustfree when removing impurities.

2. Finer Finish: Water borne abrasive cushions the cleaning process, giving a finer and higher quality finish, especially for delicate or precise products.

3. Reduce Wear. The broken rate of media is decreased due to the cushioning from the water, and the blasting tool also gets less wear, as a results that wet blasting reduces production cost.

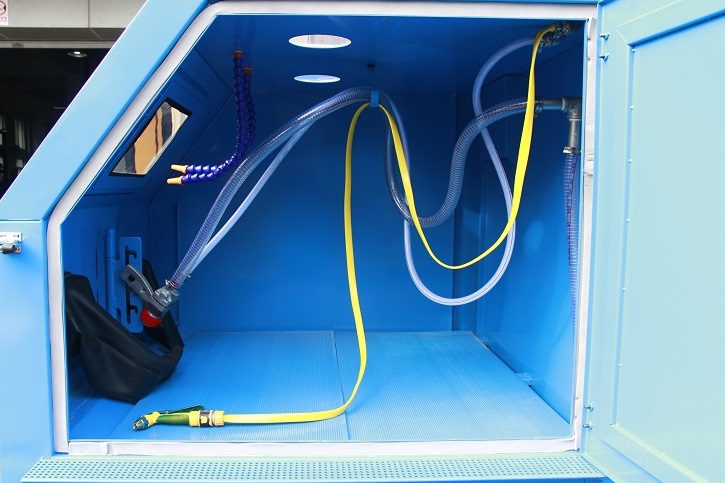

We can design wet sand blast cabinet with different sizes and comfigurations, such as adding a turntable,

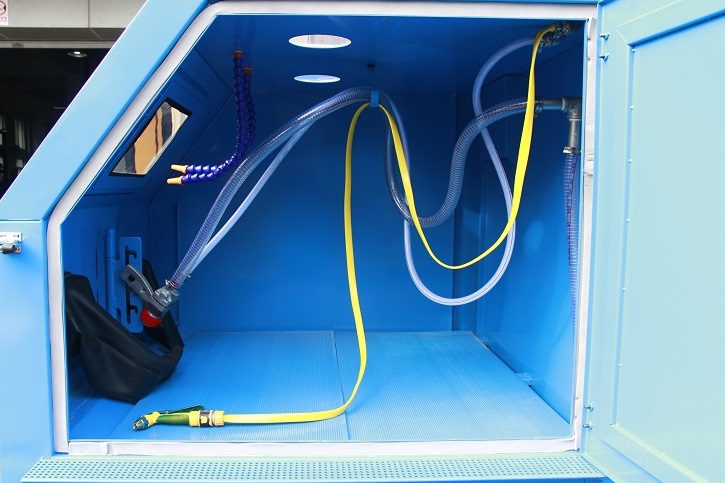

wet blasting cabinet

wet blasting cabinet with turntable

Kafan Wet Abrasive Blasting Cabinet Features

Made 3mm thick stainless steel with powder-coated surface, rigid and anti-rust.

Windscreen wiper's wash facility maintains visibility throughout the working chamber

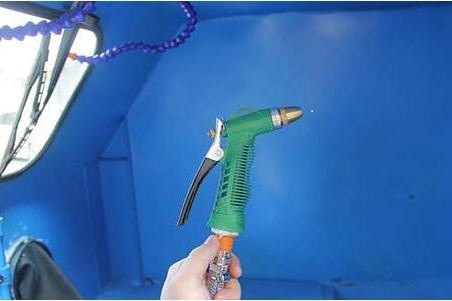

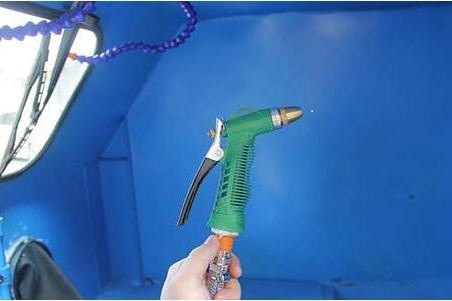

Durable wet blast gun with 8mm boron carbide nozzles specially for wet blasting process,

Reliable foot pedal controls the working of blast gun to increase operation safety.

A demister at the back of the machine for better view of blasting process.

Abrasive can be effectively recycled that causes less consumption.

Simple structured wet blast cabinet requires less maintenance.

window washer

foot switch

wet blast gun

water gun

KF-1212W Wet Abrasive Blasting Cabinet Specifications

| Model | KF-1212W |

| Outer size | 1300*1600*2000mm |

| Working area | 1200*1200*800mm |

| Motor | 2.2Kw |

| Air requirement | flow 0.5-1.1m^3/min |

| Light | 2*18w saving lamps |

| Blast Gun | 1 pc of wet blast gun with 1 boron cabide nozzle (8mm) |

| Air consumption for 1 gun | 0.4-0.8Mbar |

| Volume of abrasive & water | 25L |

| Suitable abrasive | Glass beads(for aluminum, stainless steel) Brown Aluminum Oxide(stell or other)80#-320# |

| Feed abrasive | 4-6kg |

| Abrasive : Water | 1:3 |

| Voltage | 380V/220V 3 phase (customized)

|

Standard models of Wet Blasting Cabinet for Choice

| Model | KF-1610W (double gun) | KF-1010W | KF-9080W |

| Working size | 1600*1000*800mm | 1000*1000*800mm | 900*900*800mm |

| Weight | 320kgs | 300kgs | 280kgs |

| Loading Capacity | 100-140kgs | 50-80kgs | 30-50kgs

|

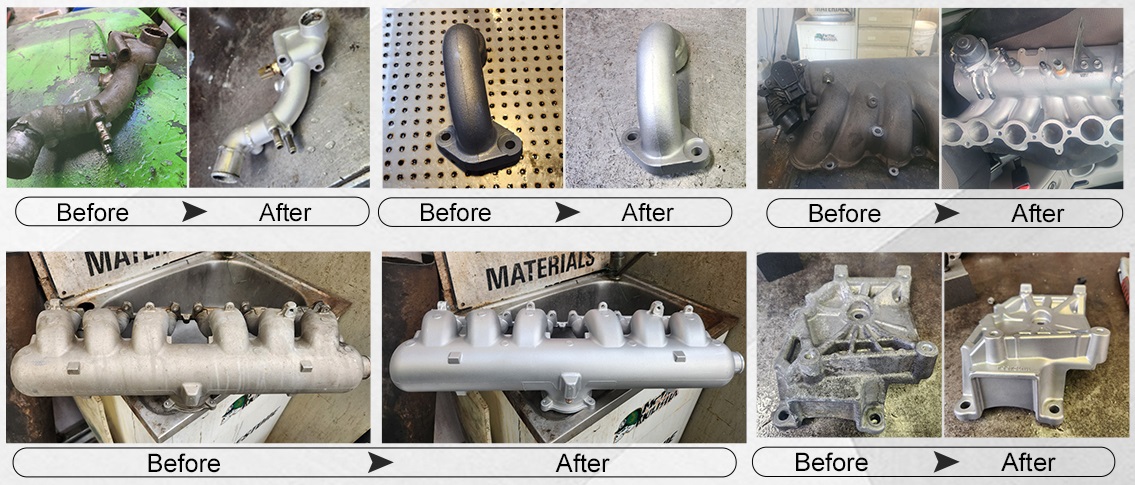

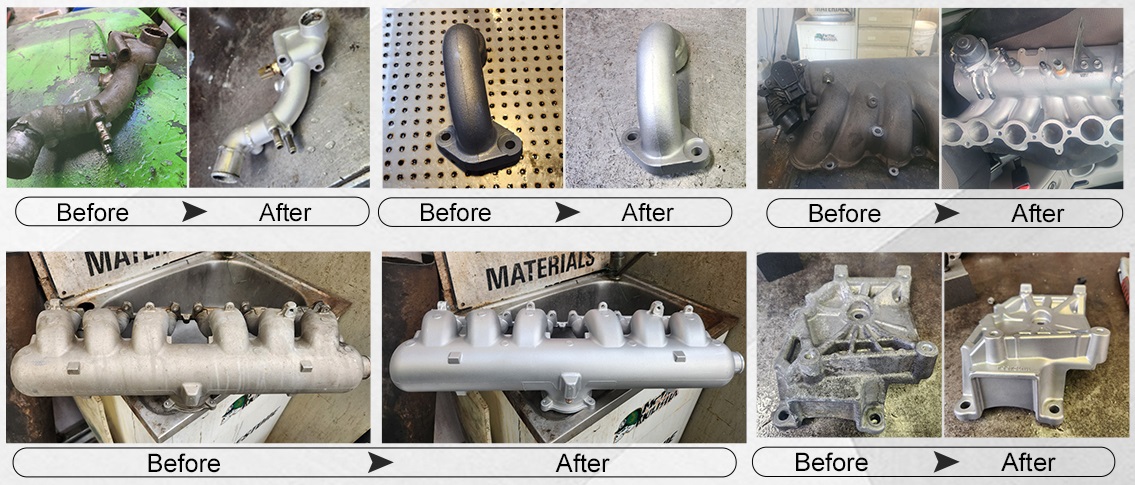

Wet Abrasive Blasting Cabinet Applications

Wet blasting leaves the underlying component completely intact with its original dimensions, whilst removing the unwanted materials So it is rapidly expanding into many restoration sectors where quality and servicing is critical.

Perfect for motors, cylinder heads, sub-sea components, aviation parts, crank cases, wheel hubs, suspension parts, bolts, master cylinders, brake calipers and valuable restoration projects.

Effective for cleaning of dies and moulds, removal of pain, rust, scale, carbon and similar deposits.

Surface preparation prior to bonding, re-painting and powder coating.

Aqua Blasting will also produce a very uniform satin finish especially on aluminium or stainess steel items returning the material to as new casting appearance

Finishing of stainless steel and other metals, cleaning of PCBs and electrical components and so on.

As the media material can be varied the gentle cleaning action of Aqua Blasting is not limited to metals and cleans exceptionally well with plastics and rubbers.