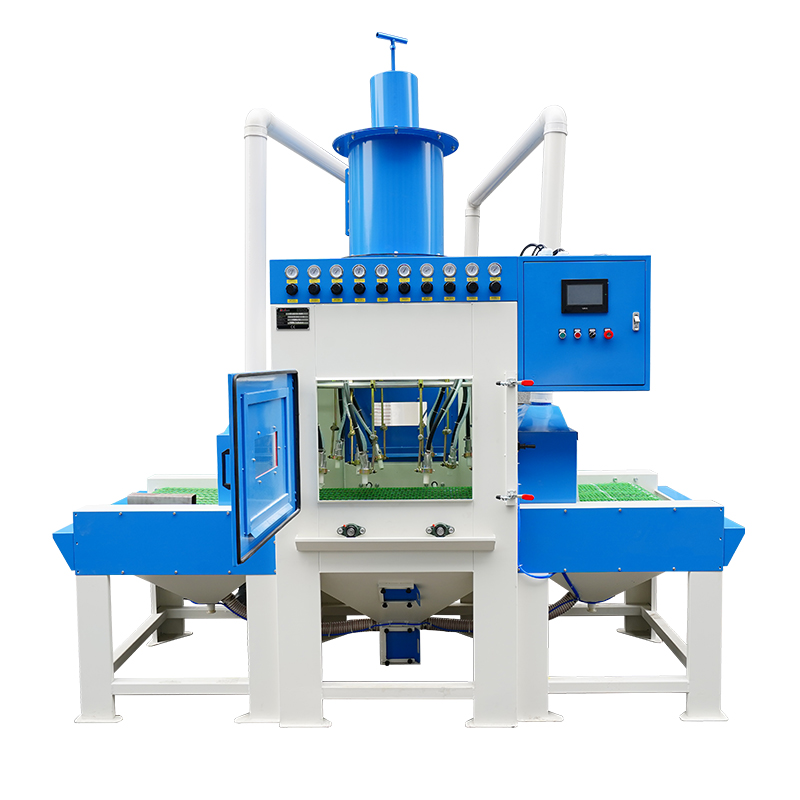

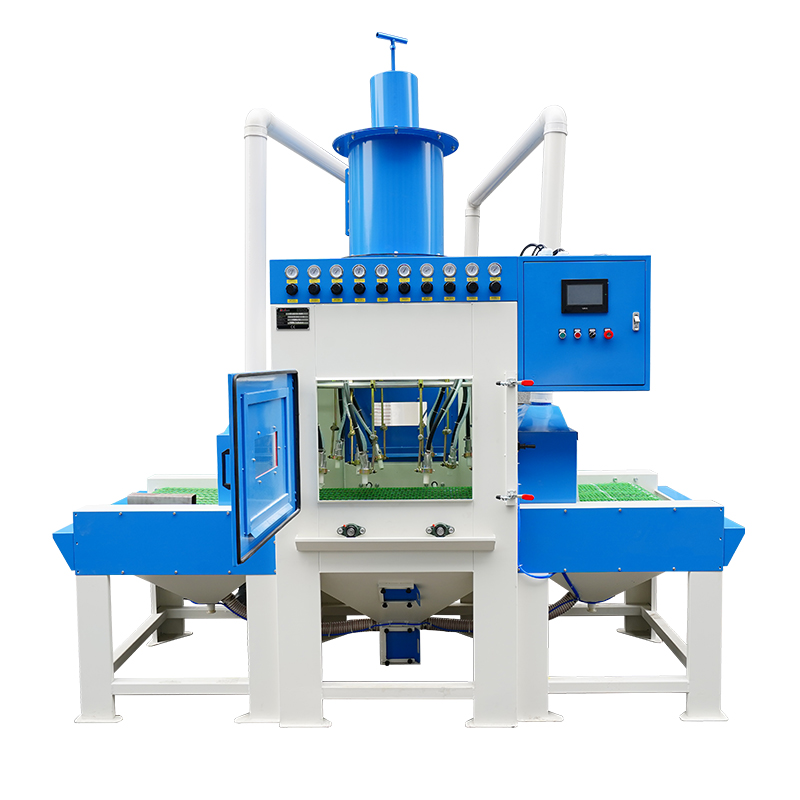

Automated Sandblasting Equipment with Horizontal Conveyor

In our through-belt machines, components are continuously presented to an array of pre-positioned guns as the parts are conveyed in and out of the blast chamber on an adjustable-speed rubber or steel mesh belt. Up to 10 suction-blast guns are bracketed to sweep parts in linear motion synchronized with continuous movement of the belt.

Why choose a conveyor sandblasting equipment?

Application: ideal for processing flat shaped workpieces such as: aluminum plate, glass plates, ceramic tile, steel plate, stainless steel plate, mobile shell, notebook computer shell, etc Widely used for cleaning contaminants, etching and decorating, roughing surface, descaling, removing rust and old coatings, etc

Advantages Automated blasting equipment features high finishing efficiency. The finished surface of the product is clean without sticky debris. In particular, automatic sandblasting avoids the uneven blasting effect, chromatic aberration and quality problem.

Automated Sandblasting Equipment Features

1. The belt conveyor speed can be steplessly regulated by the inverter based on actual needs.

2. The quantity of blasting guns can be configured 8pcs, 12 pcs, 16 pcs or more, Nozzles in wear-resistant boron carbide material.

3. Auto blast guns can be controlled with adjustable swinging speed and angle, in order to cover more surface area.

4. Using advanced PLC control system achieves high automation and stability, low failure rate.

5. Independent filter dust collector, powerfully remove dust, keeps the working chamber dustless and increases abrasive recyling rate.

Auto Blasting Guns

PLC Control System

Dust Collector

Automated Sandblasting Equipment Specifications

| Type: | Pass Though Conveyor Type |

| Model: | KF-6010-10A |

| Machine dimensions: | Length3200 * Width1400 * Height2400 mm |

| Working Space size: | Length1000 * Width1300 * Height1000 mm |

| Through Size | Length800 * Width300 mm |

| Dust collector size: | Length1200 * Width700 * Height1900mm |

| Dust Collector Filter Qty | 6pcs |

| Dust fan motor power: | 5.5kw |

| Blast gun swing motor: | 370W 380V 50HZ |

| Lighting: | 18W fluorescent lamps, 2pcs |

| The number of blast nozzles: | 10pcs ( boron carbide nozzle) |

| Machine Shell: | 2.5mm-6mm cold-rolled steel plate welded |

| Perspective window: | 2 frames |

| Abrasive funnel | 3pcs |

| Pressure | 5-8 bar (kg / cm2) |

| Air compressor | 6.8 cubic meter |

| Conveyor loading capacity: | 300 kg |

| Total power: | 8.8KW |

| Total weight: | 1.55 tons |

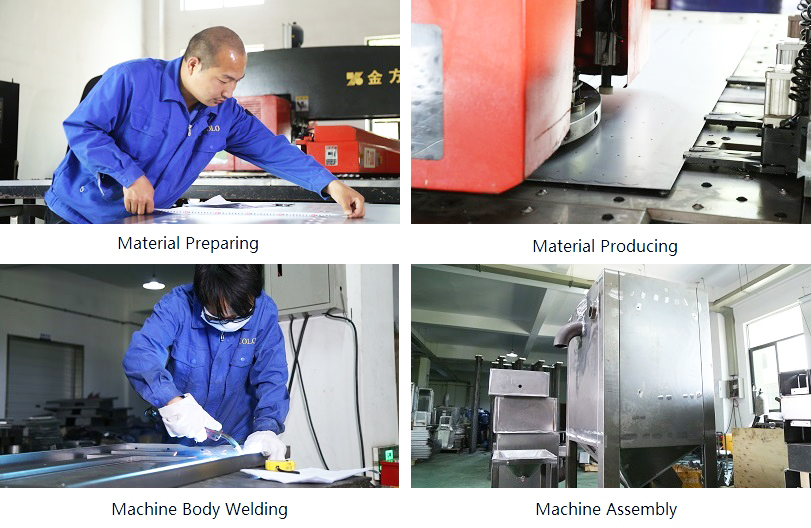

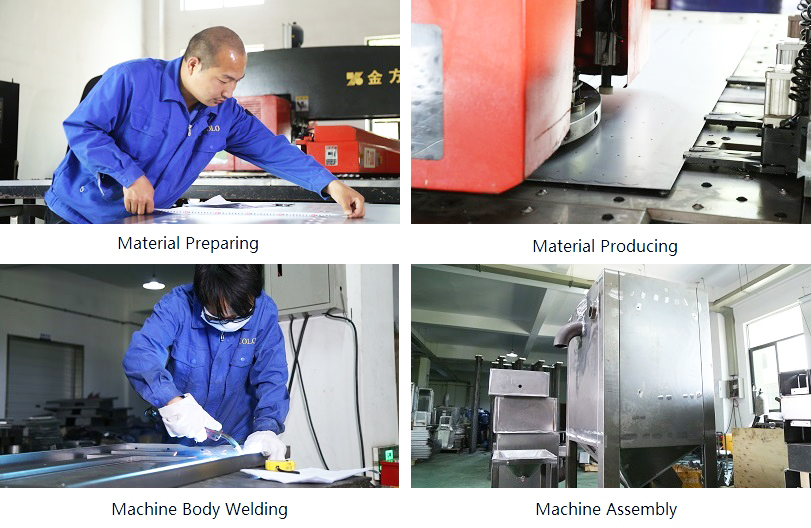

Why choose Kafan sandblasting equipment?

All sandblasting machines were made in house by rich experienced production team of Kafan, we can directly control the cost and quality.. To pursue best performance, each machine body is steel plate welded with powder coated surface, durable, wear-resistant and long lifespan, and the main components are imported, by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.