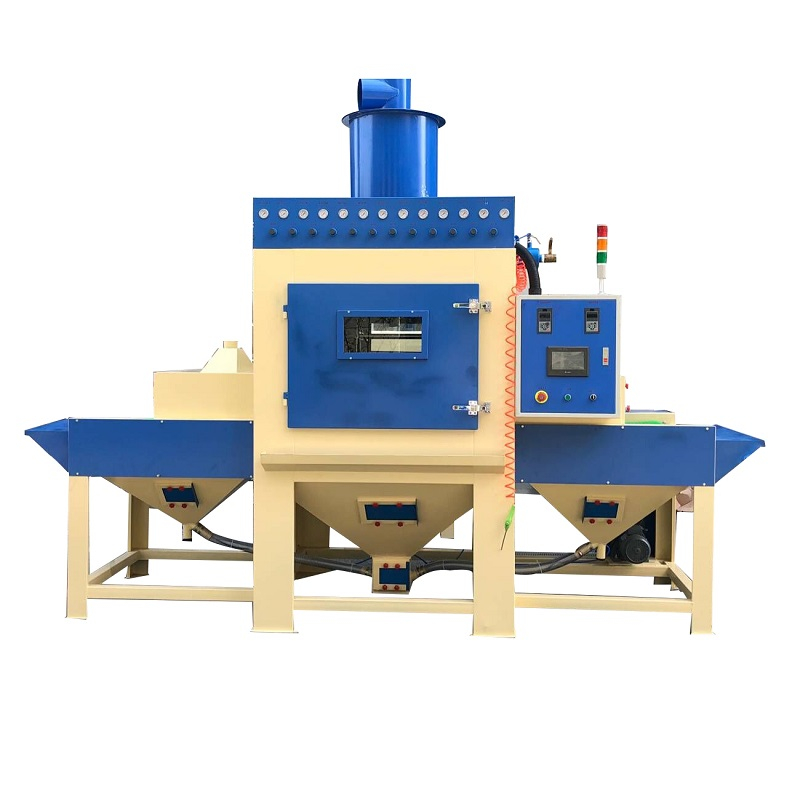

Horizontal Conveyor Automatic Sandblasting Machine

In our pass through conveyor blasting machines, workparts are continuously presented to an array of pre-positioned guns, the certain quantity of suction-blast guns are bracketed to sweep parts in linear motion synchronized with continuous movement of the belt. As the parts are conveyed in and out of the blast chamber on an adjustable-speed rubber or steel mesh belt.

How to use the horizontal conveyor sandblasting machine?

Operator puts the products on the one side of the conveyor, the belt will transport them into the sandblasting room for automatic sandblasting. After blasting, the products will be delivered to be cleaned by air blowing gun.Finally conveyor belt automatically bring the product out of the machine.The entire process is automatically and continuously completed.

Horizontal Conveyor Automatic Sandblasting Machine Features:

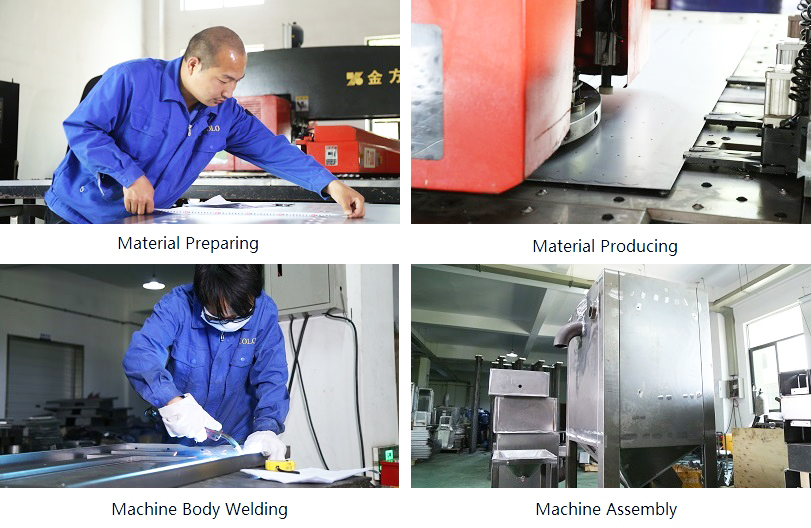

The Kafan conveyor sandblasting machine body is made of cold-rolled steel plate by electrostatic powder spraying, featuring long lifespan, durable, anti-rust and not easy to scratch.

It is configured with an cyclone separator and an Independent cartridge filter dust removal system with effective dust extraction and ventilation, which ensure environmental-friendly standards There are three abrasive funnels at the bottom of the blaster, ensures all used abrasives are recycled, reduce consumption and save cost

The style and specifications of conveyor sandblasting machine can be customized according to the size, shape, productivity of actual production needs.

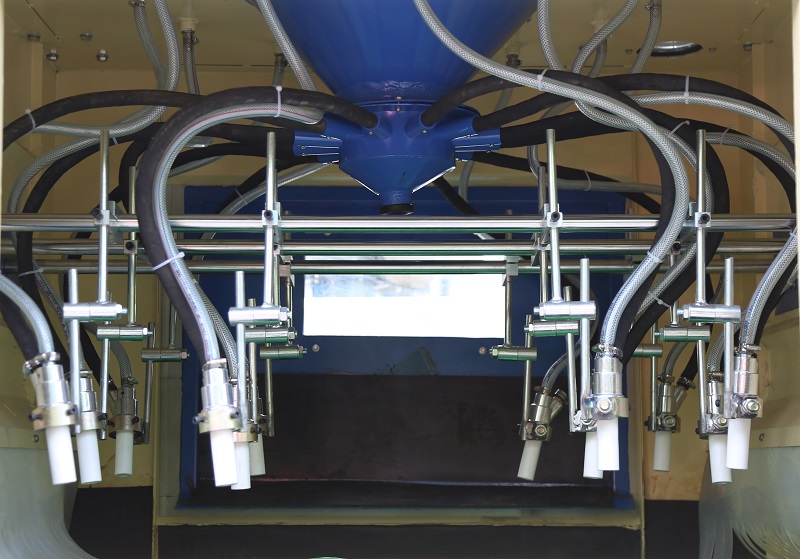

Automatic Blasting Gun

The conveyor blast machine consists of 12pcs(quantity can be customized) blast gun which is casting aluminum alloy, and the nozzle is high-quality wear-resistant boron carbide material. Nozzle diameter: Ф8mm. The gun distance, swinging angle and position can be adjusted according to the actual products, you can also choose full swinging or non-swinging for the gun. Each blast gun is individually controlled.

Belt Conveying System

The motor of the conveyor is Taiwan brand, three-phase gear motor, power 0.75kw. The motor is controlled by frequency converter, the conveyor speed can be steplessly regulated by the inverter within the range of 0 ~ 2m / min. The conveyor speed can be set based on actual products and requirements to achieve optimal finishing results.

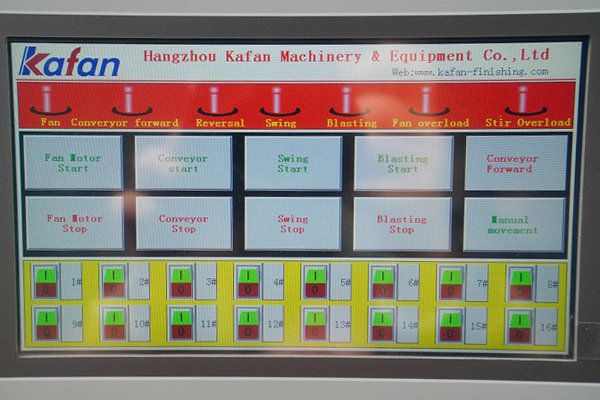

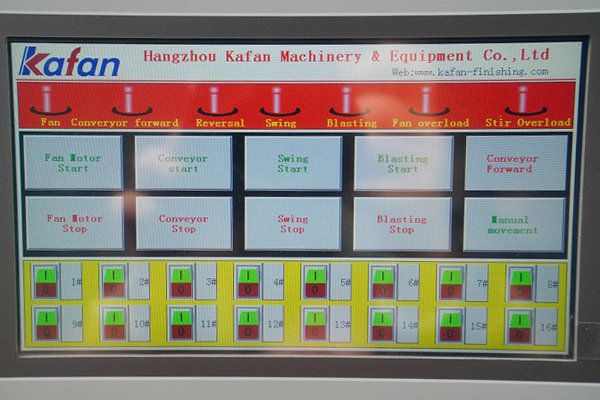

PLC Automatic Control System

Using advanced PLC system for electric and pneumatic control, a high degree of automation, good stability, low failure rate. The touching screen offers user-friendly interface to manage the blast working, adjust conveyor speed or start the dust collector. High automation guarantees the balanced uniform blasting effect, as well as safe production.

Horizontal Conveyor Automatic Sandblasting Machine Specifications:

| Model: | KF-3510ZS-12A |

| Machine dimensions: | Length3500 * Width1100 * Height3200mm |

| Working room size: | Length3200 * Width1000 * Height650mm |

| Dust collector size: | Length1000 * Width1150 * Height1800mm |

| Dust fan motor power: | 3KW 380V 50HZ |

| Blast gun swing motor: | 370W 380V 50HZ |

| Lighting: | 18W fluorescent lamps, 2pcs |

| The number of blast nozzles: | 12pcs (aluminum alloy body with boron carbide nozzle) |

| Machine Shell: | 2.5mm-6mm cold-rolled steel plate welded |

| Perspective window: | 2 frames |

| Abrasive funnel | 3pcs |

| Pressure | 5-8 bar (kg / cm2) |

| Air compressor | 6.8 cubic meter |

| Conveyor loading capacity: | 50 kg |

| Total power: | 4.75KW |

| Total weight: | 1.55 tons |

Automatic conveyor sandblasting machine application:

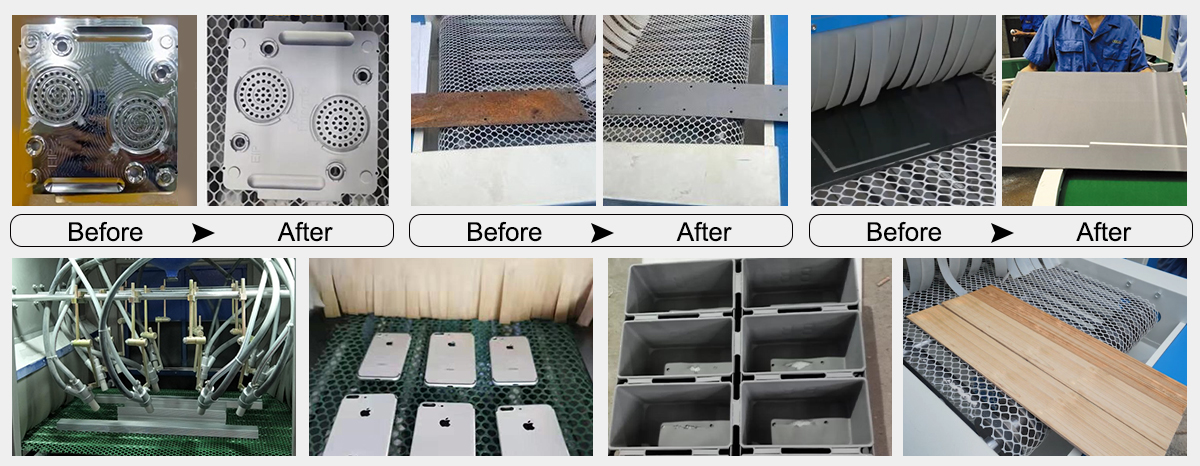

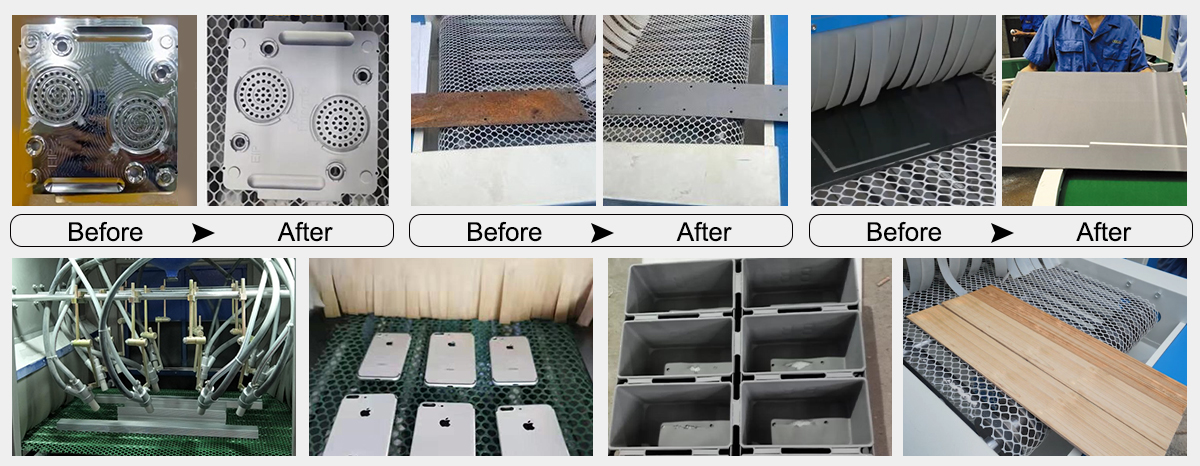

It is ideal for operating flat shaped workpieces such as: aluminum plate, glass, ceramic tile, steel plate, stainless steel plate, mobile shell, notebook computer shell. The blasting system can do the job including: cleaning contaminants, etching and decorating, roughing surface, descaling, removing burrs, stripping rust and old painting, improve the surface adhesion before painting and powder coating.

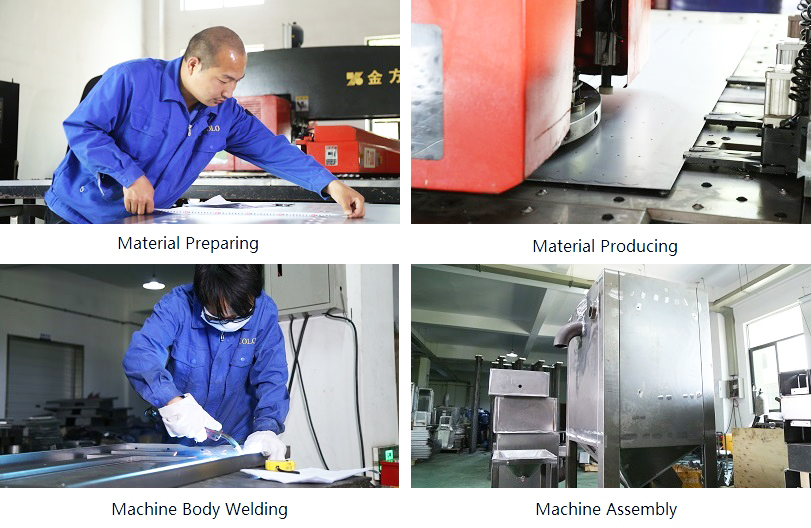

Why choose Kafan automatic sandblasting machines?

All sandblasting machines were made in house by rich experienced production team of Kafan, we can directly control the cost and quality.. To pursue best performance, each machine body is steel plate welded with powder coated surface, durable, wear-resistant and long lifespan, and the main components are imported, by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.