Indexing Turntable Automated Sand Blaster for Batch Cyclindrical Parts

This automated sand blaster is configured with a large indexing turntable and fitted with multiple small turntables inserted with workparts. The indexing turntable intermittently rotates to present the workparts in accurate position in front of the automatic blast guns for process, while each small turntable rotates itself ensure all the surface to be covered with abrasive flow.

Why Choose an Indexing Turntable Automated Sand Blaster

1) The highly-efficient automated sandblasting machine designed with an opening stand for operators loading and unloading and a closed cabin with a group of guns for blast processing, these simultaneous jobs greatly reduces task times.

2) The 360 degree indexing turntable and multipe small turntables allows processing workparts in complex shapes and provides optimum blast coverage for all sides surfaces.

3) Higher volumes, increased productivity and a drive to safe automated systems demands makes this sandblasting system a rapid, repeatable and reliable equipment.

Multi-turntable Automatic Sandblasting System Features:

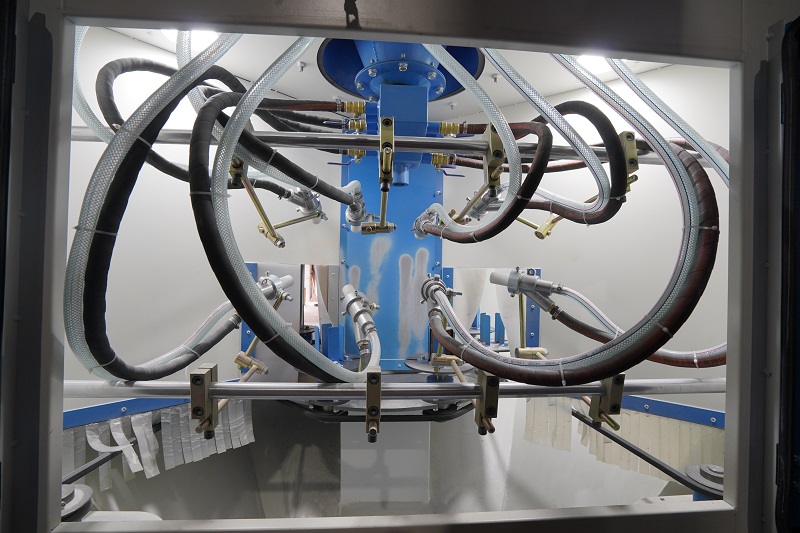

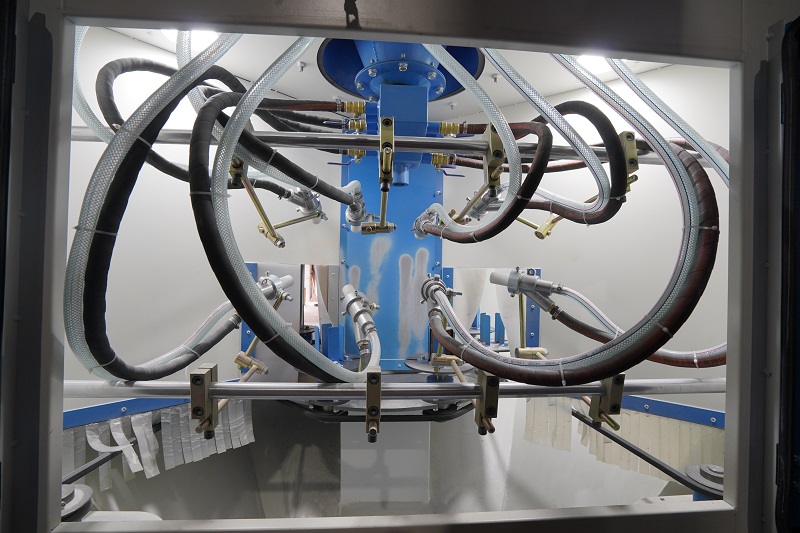

Automatic Blast Guns

Workparts are rotated to the blasting area where they are processed by a group of automatic sandblasting guns.

Each blast gun is individually controlled for working by demands. Depending on the parts shapes and dimensions, the blast guns can be set for fixed blasting or oscillating blasting with adjustable angles.

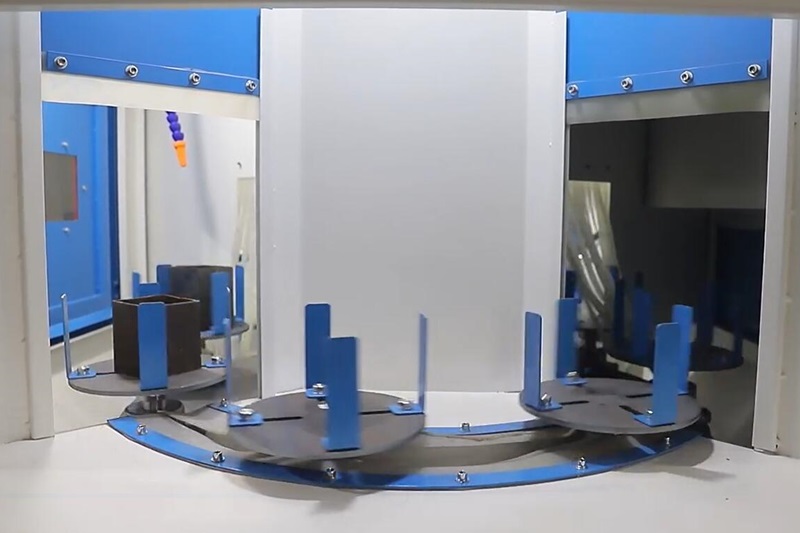

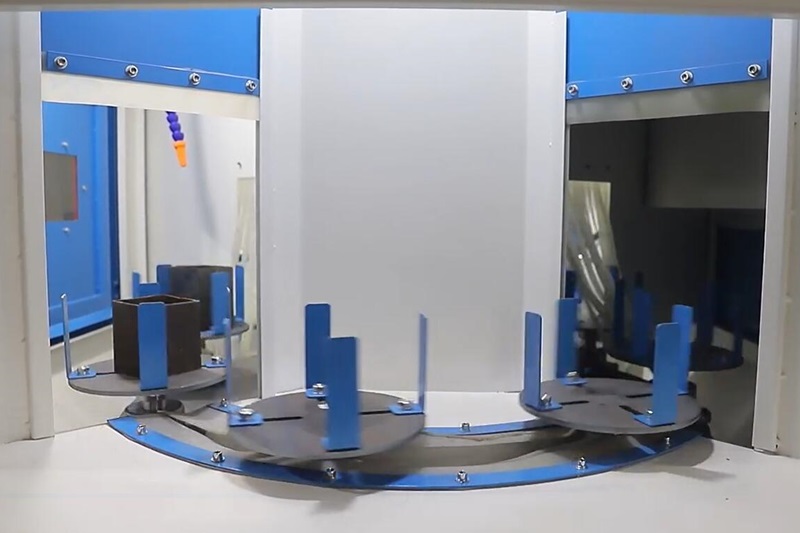

Multiple Working Platforms - Small Turntables

Multiple small working turntables loading workparts are evenly spaced on the big index turntable.

The big turntable present small turntables in front of blast gun for automatic processing.

Adaptable turntable with fixture can be configured to suit your workparts and processing requirements.

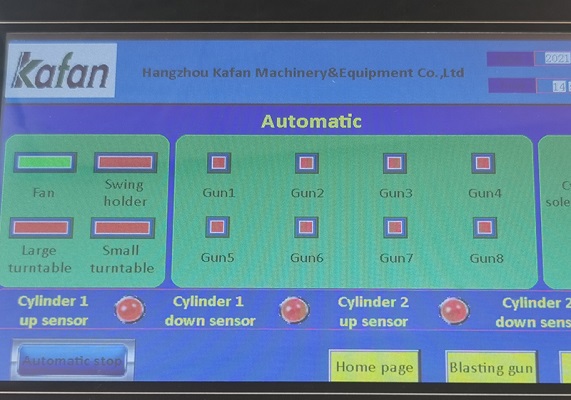

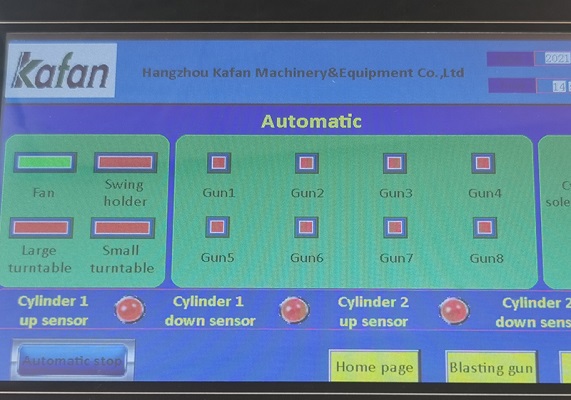

PLC Control with Touching Screen

High automation and accuracy task controlled by PLC system, guarantee the balanced uniform blasting effect, as well as safe production.

The touching screen offers user-friendly interface to manage the blast working, such as adjust the rotating speed, set blast time, control each blast gun and set the dust collector.

Dust Removing & Media Recycling

Designed with cyclone separator for effectively separation of abrasives from dusts. Along with an independent cartridge filter dust removal system with excellent effect of dust extraction and ventilation. Blast-removed dust particles are exhausted to the dust collector while blast media is collected at the bottom of the cabinet, then returned to the storage hopper for further use.

Indexing Turntable Automated Sand Blaster Specifications

| Model: | KF-1512-8A |

| Main Dimension | 1500x1200x2000mm |

| Dust Collector Size | 1200x1200x1700mm |

| Large Turntable Size | Dia 900mm |

| Drive Motor Power | 1.1kw |

| Qty of Small Turntables | 8 sets |

| Drive Motor Power | 0.75kw |

| Max. Size of Parts Allowed | Dia 250mm x Height 350mm |

| Qty of Blast Guns | 8 pcs |

| Blast Gun Nozzle | Durable Boron Carbide |

| Power Supply | 380V/220V As required |

| Separator Motor | 5.5kw |

| Compressed Air Source | 2-8bar (kg / cm2) |

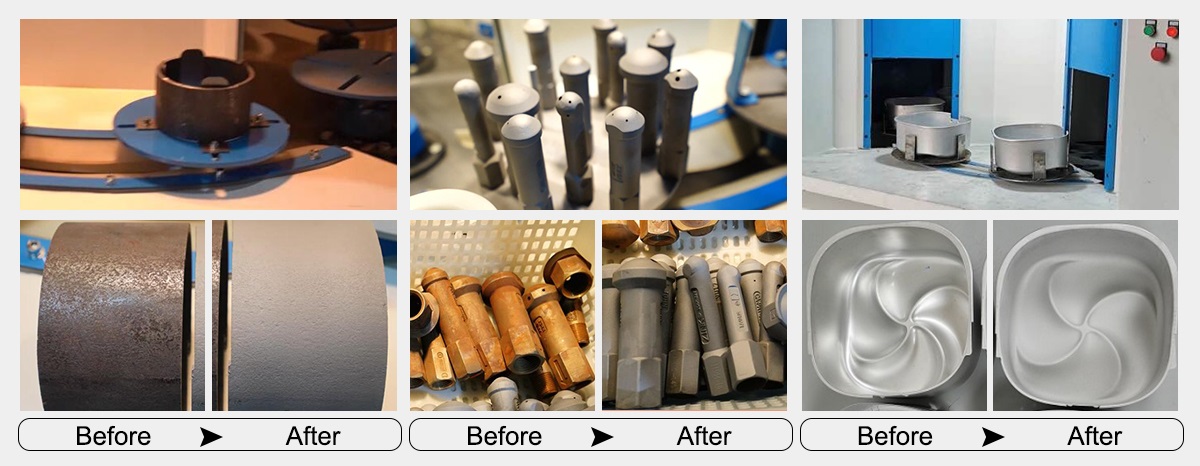

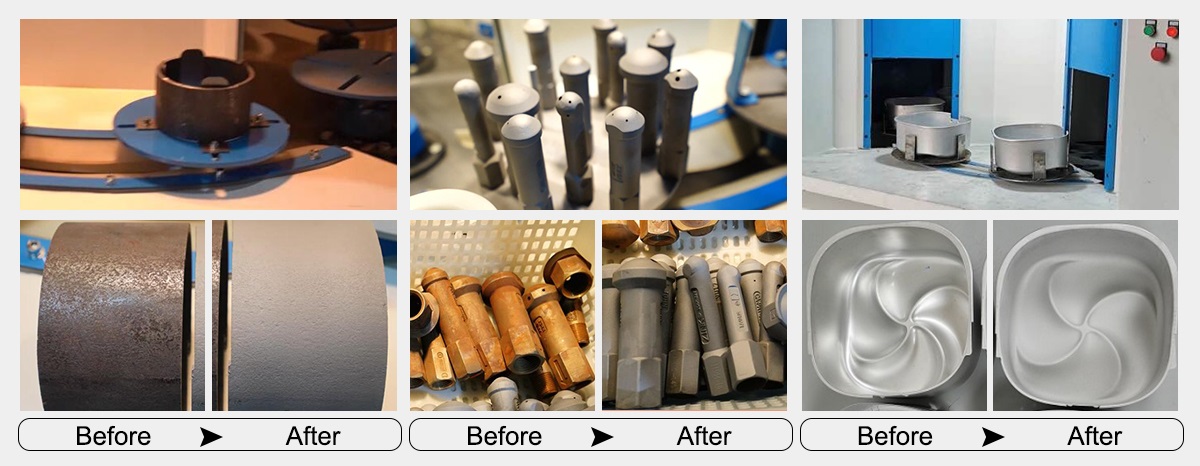

Indexing Turntable Automated Sand Blaster Application

It is suitable for mass production of discs, cylinders and polygonal shape parts, such as: rice cookers, non-stick pan, heating plates, baking pan (furnace), air cylinders castings, lampshade, wash pots, wine bottles, glass bottles, resin handicrafts, aluminum corridors, handicrafts, decorations and other products. Based on actual production needs, the automated sand blaster can be customized with specially turntables, different gun quantities, etc.