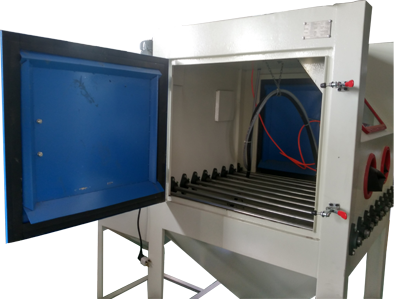

Heavy-duty Manual Sand Blasting Machine

Heavy-duty Manual Sand Blasting Machine

Roller type sand blast machine is customized for applying to heavy-duty products such as: like marbles, granite, molds. The working cabinet is specially designed with roller conveyor, which provides an easy movement for parts.

The manual suction blast machine often features simple operation and limited budget, yet also regarded as a versatile model, cleaning contaminants, removing rust and scale, light deburring and decorating, all can be achieved in one sandblasting machine.

Features of Roller Sand Blasting Machine

With two-side doors opening can achieve easy loading and unloading of big or heavy products.

Cartridge filter dust collector effectively remove dust from the working chamber to ensures high visibility.

An abrasive reclaim system is incorporated for continuous recycling of abrasive, saving cost.

Well sealed blasting cabinet with no abrasive and dust leakage is no harm to operators.

Equip an durable blasting gun with boron carbide nozzle, diameter 6mm, 8mm, 10mm, 12mm for choice.

Safe foot pedal switch to control the work of blasting gun, reduces the user’s fatigue and facilitates the operation.

Sand Blasting Machine Working principle

The blast machine use compressed air as the driving force forming a high-speed jet to blast the abrasive on the target surface. Due to the impact of abrasive the surface gets certain cleanliness and different roughness based on requirements. In this case, the mechanical properties of the surface changed, for example, increasing the adhesion before powder coating, painting or plating.

Roller Sand Blasting Machine Specifications

| Model | KF-1010C |

| Working Dimension(mm) | L1000 x W1000 x H800 |

| Roller Count | 9 pcs |

| Door | 2 sides opening |

| Power Supply | 380V 50Hz |

| Seperator Motor | 380V 50Hz 5.5kw |

| Seperator Air Flow | 10m^3/min |

| Compressed Air Source | 2-8bar (kg/cm^2) |

| Operation | Manual

|

| Lighting | 50w LED |

| Standard load capacity | 100kg |

| Nozzle | Boron Carbide |

| Blast Gun Control | Food Pedal. |

Why choose kafan sand blasting machine?

With a sand blasting machine, you will easily prepare metals, glass, ceramic, wood products considering less commissioning and maintenance. The blasting equipment allows abrasives penetrate into awkward corners and cavities making it perfect to operate irregular shaped parts, while it is tough jobs for manpower.

With over 10 years manufacture experience, Kafan always offer customer-based practical equipment, you can find manual blasting cabinet, wet blast cabinet, automatic sandblasting machine, pressure blaster in Kafan. Using the latest technology for our blast components, fully welded with 2mm steel for the cabinets, our blast machine has proven the reliability. We design and manufacture in-house.