Centrifugal Barrel Deburring Machine

Centrifugal barrel deburring machine provides extremely intensive processing, which tends to attack sharp edges, remove heavy burrs and round off corners more effectively than other mass finishing methods. By powerful centrifugal force, the deburring machine creates very safe surfaces, such as casting parts, stamping parts and other industrial accessories.

Centrifugal Barrel Deburring Machine Features

4 barrels in the inner cavity of the machine which can handle different workpieces at the same time to avoid collision.

Built with polyurethane lining that reduce impact damage during tumbling action.

The upper part of the machine is provided with an arc cover, which is a movable sliding door, with the cover closed during working to ensure safety.

Can be matched with the frequency converter, aims to the precisely adjusting rotational speed, supports different products and demands, optimize finishing effect.

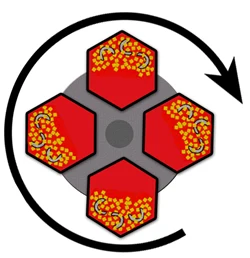

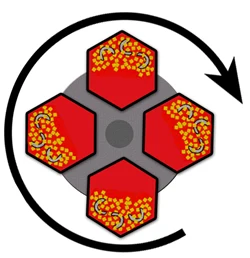

How does centrifugal barrel deburring machine work?

Each centrifugal barrel machine contains four barrels that are mounted to a drum. The operator fills the barrel with media, parts and water, roughly 50-90% full. During operation the entire drum of the debur tool rotates like a Ferris wheel. As the speed increases, the media and parts rub against one another randomly and repeatedly, removing smallest imperfections. In a matter of minutes the finishing cycle is complete and the parts are ready to be separated from the media

Centrifugal Barrel Deburring Machine Specifications

We offers centrifugal barrel finishing machines in a wide variety of sizes to fit any production needs

| Model | Capacity | Motor Power | Speed | Inner Lining | Weight | Size(L*W*H) |

| KFW-15 | 2*7.5L | 1.1kw | 185r/min | 5-8mm | 200kg | 850*880*980mm |

| KFW-30 | 4*7.5L | 1.5kw | 185r/min | 5-8mm | 350kg | 970*990*1175mm |

| KFW-40 | 4*10L | 2.2kw | 165r/min | 6-10mm | 800kg | 1100*1000*1400mm |

| KFW-60 | 4*15L | 5.5kw | 165r/min | 8-12mm | 1000kg | 1150*1100*1700 |

| KFW-80 | 4*20L | 5.5kw | 145r/min | 8-12mm | 1200kg | 1300*1250*1815mm |

Centrifugal Barrel Deburring Machine Applications

For batch processing of complex surface of the small and medium-sized workpiece.

Remove the workpiece surface of the burrs, oxide, oil, flash, rough throw, fine throw.

Suitable for copper, iron, aluminum, steel and other micro-metal parts

The use of centrifugal movement working principle improves work efficiency 10-20 times, especially for heavy and tough jobs.

If you want to find difference between centrifugal barrel finisher & vibratory finisher, visit

Centrifugal Barrel Finishing VS Vibratory Finishing