60L Centrifugal Barrel Tumbler Machine

The strong centrifugal force can effectively remove heavy burrs, sharp edges to create safe surface. For polishing demands, parts are finished in high precision and high brightness. Centrifugal barrel finishing machine is ideally to prepare metal or non-metal parts.

Kafan Centrifugal Barrel Tumbler Features

The 60L centrifugal barrel tumbler is mounted with 4 pcs 15L tumbling barrels

The barrel inner wall is built with wWear resistant and long life polyurethanes to extend its service life.

An arc-shaped sliding cover shields the base, start the machine with cover closed to ensure safety and keep quiet.

Can be configured with variable speed meets different finish desires from light polishing to heavy deburring or edge cutting.

Centrifugal Barrel Tumbling Machine Specifications

We offer centrifugal barrel machines in a wide variety of sizes to fit any production need

| Model | Capacity | Motor Power | Speed | Inner Lining | Weight | Size(L*W*H) |

| KFW-15 | 2*7.5L | 1.1kw | 185r/min | 5-8mm | 200kg | 850*880*980mm |

| KFW-30 | 4*7.5L | 1.5kw | 185r/min | 5-8mm | 350kg | 970*990*1175mm |

| KFW-40 | 4*10L | 2.2kw | 165r/min | 6-10mm | 800kg | 1100*1000*1400mm |

| KFW-60 | 4*15L | 5.5kw | 165r/min | 8-12mm | 1000kg | 1150*1100*1700 |

| KFW-80 | 4*20L | 5.5kw | 145r/min | 8-12mm | 1200kg | 1300*1250*1815mm |

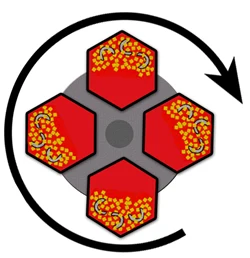

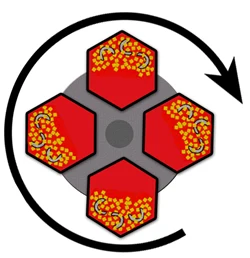

How does centrifugal barrel tumbler work?

Each centrifugal tumbling machine contains four barrels that are mounted to a drum. The operator fills the barrel with media, parts and compounds roughly up to 50-90% full. During operation the entire drum of the debur tool rotates like a Ferris wheel. As the speed increases, the media and parts rub against with each other randomly and repeatedly, removing even most tough imperfections. In a matter of minutes the finishing cycle is completed and the parts are ready to be separated from the media