Crawler Belt Automatic Sand Blasting Machine

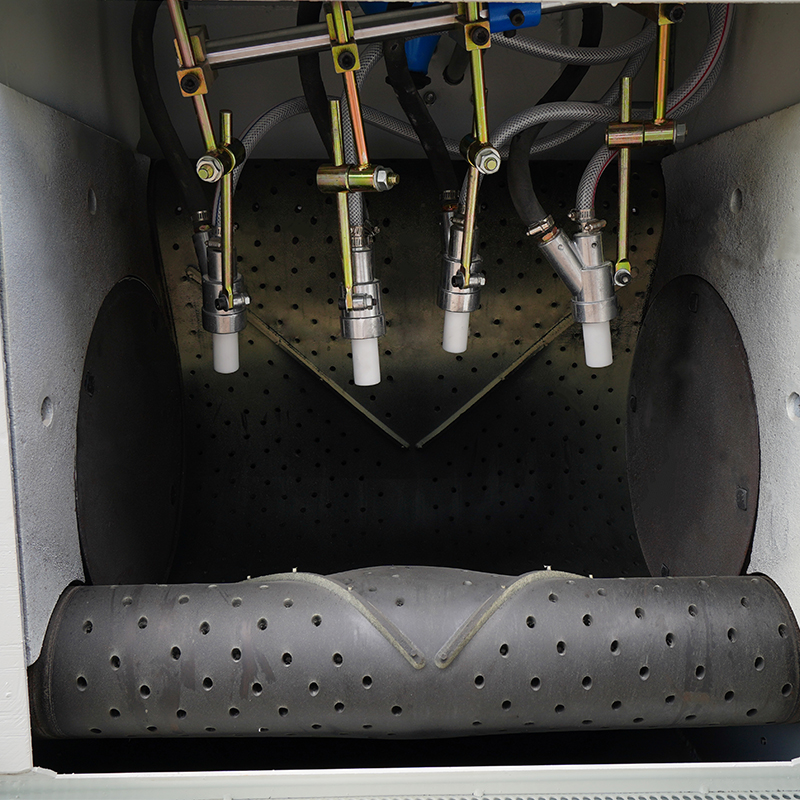

The space-saving crawler belt blast machine achieves automatic procesing of batch pieces at a time. The rubber belt keeps parts gently tumbling as they are exposed to blast abrasives on all surfaces, which Simplifies the surface treatment of small to medium sized, hard-to-hold pieces. even delicate parts.

Crawler Belt Blasting Machine Features

1. Long life, wear-resistant rubber belt with a loading capacity of 100kgs.

2. Blasting guns are composed of boron carbide nozzles, which is the most durable materials in the market.

3. Easy-to-use electric control to adjust blasting pressures, belt tumbling speed, and blasting cycle time, etc.

4. Blast media is continuously separated from dust by a cyclone device, returning only pure blast media in good shape back to the blast nozzles for optimal results.

5. Configured a pulse filter cartridge for dust removal system, features high removal efficiency and requires easy installation and maintenance.

6. The blast guns quanity, swing speed, rubber belt size, all can be tailored to the customers specifications to address all process constraints and for optimal results and productivity.

Crawler Belt Blasting Machine Specifications

Model

| KF-A100

|

Working cabinet: | L900*W600*H600 (mm) |

Cabinet outsize: | L1160*W1000*H2800 (mm) |

Dust collector dimensions: | L1200*W900*H2140mm |

Productivity:

| 0.3-0.5 T/H |

Load capacity: | ≤200KGS |

Tumbling motor power:

| 1.5KW |

Dust collection motor power:

| 3.0KW |

Automatic blasting gun: | 6pcs Aluminium alloy blasting guns, with 4pcs boron carbide nozzles, dia 8mm. |

Voltage: | 380V/220V 50HZ (can be customized)

|