1. How much time does it take to sandblasting for one piece cooking pan approximetly?

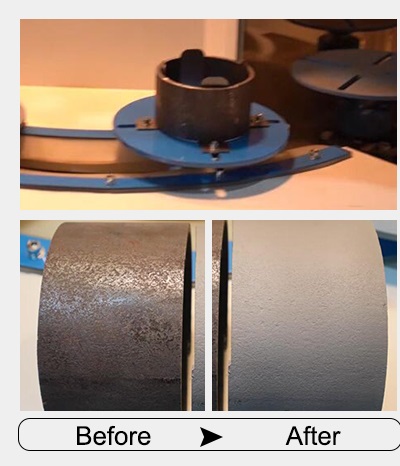

About the cycle time, it takes about 20-30 seconds to blast one pan according to the feedback from our clients who bought the automatic blast machine working with pans.

2. After we buy this automatic sandblaster, just giving power and loading the sand will be enough for using this machine?

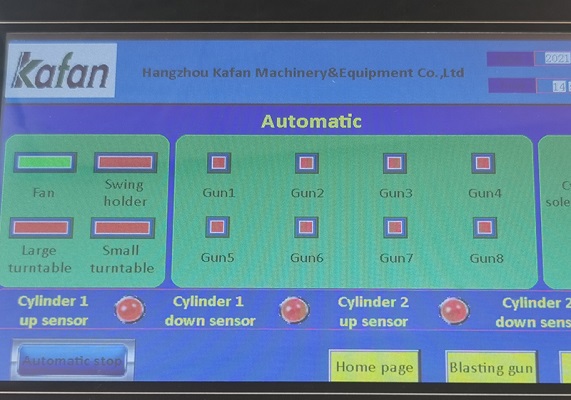

Yeah, the offer includes all parts. Ready to use. After connecting with air source and power source. It can begin to work after loading the sand.

3. In this picture, the machine has a square cabinet which stands behind or beside it. what is it?

For the one standing behind or beside the machine, it is the catridge filter dust collector. The filter unit keeps the environment clean and dustless.

4. Which type of sand could be used in this machine?

The machine can work with various sands, size from mesh 16 to mesh 320, like glass beads, aluminum oxide, garnet, steel grit, corundum, etc.

5. Is this rotary indexing machine blasting just cover the cap or it sanding outer and inner side at the same time?

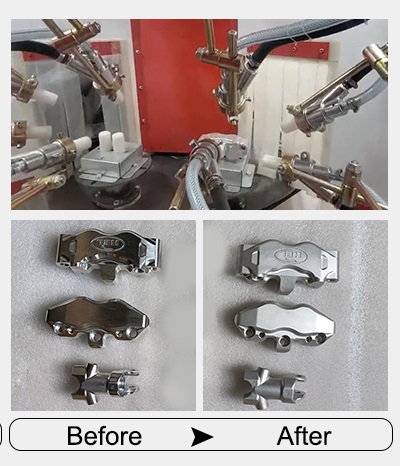

The machine can blast both outer and inner side of the pan at the same time, actually cover all surfaces of objects.. The Oscillating nozzles can be adjusted on a vertical or horizontal axis.

6. As we know it consumes sand. How much sand consuming in this process? How often should we change the whole sand?

The sand consumption is about 200kgs for 8 blasting guns each week if continuous work for 6-8 hours each day. The quantity changes as per the working time and different sand. There is no need to change the sand, just add some more when find out it is less.

7.Could we send you samples to sandblast in this automatic machine? We want to see the results.

It is good idea to send us a sample for testing in our automatic sandblasting machine. Please also send good sample for reference so that we can know what surface condition you required. If any possibility, welcome to visit our factory.