Tumble Belt Shot Blasting Machine

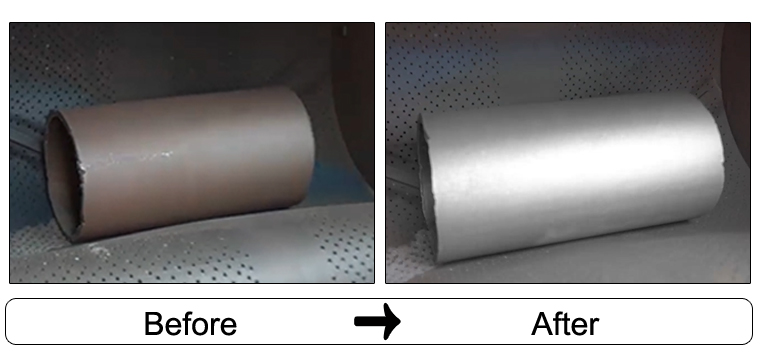

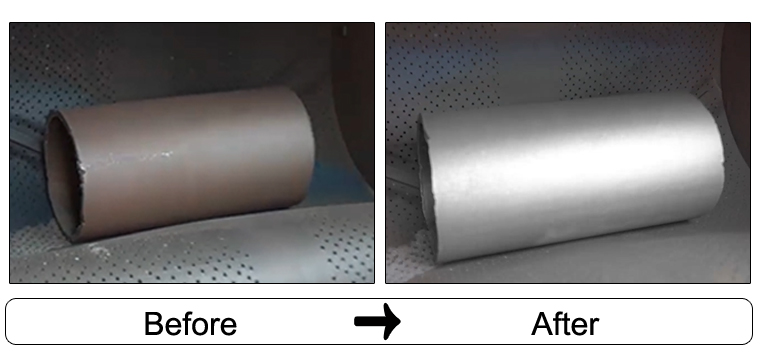

The tumble belt shot blasting machine is suited for surface treatment of small and medium sized parts in batches, such as forged, cast, pressed, heat treated components that can be finished to the highest standard.

The endless steel belt keeps parts gently tumbling as they are exposed to shot streams on all surfaces, steel shots are continuously thrown in high flow by a high speed rotating impeller.

Comparing with pneumatic tumble sandblaster, this shot blaster projectile throwing driven by a reliable electric motor which processes parts with extremely higher efficiency.

How does tumble belt shot blasting machine work?

Shot blasting machine is powered by electromechanical not by compressed air, it works through a high-speed rotating impeller to throw out steel shots in high speed and high flow, thus creates more forceful impact to surface. In the tumble belt blaster, the parts are placed in a half cylinder shaped volume by swiveling through the belt motion. At the same time, turbines located at appropriate angles blasts steel particles to cleans part surfaces.

Tumble Shot Blasting Machine Features

Perforated steel belt

The shot blasting chamber is steel and plate riveted welding structure and laid with alloy guard plates, all peform wear-resistant, impact-resistant and long lifespan.

The thick, perforated, durable belt ensures reliable tumbling of high volume workparts.

Electric control

An electric controller for easily monitor the blast process, and equipped with safety protection devices to ensure safe and effective work.

Media lifting elevator

Designed with media lifting elevator, the heavy blasting media such as steel shots after using can be lifted and delivered back to the system by the elevator.

Filter Dust Collector

Configured a pulse filter cartridge for dust removal system, features high removal efficiency and requires easy installation and maintenance;

Tumble Shot Blasting Machine Specifications

| Model | KF-S4065 |

Cabinet worksize: | Diameter 400mm * Length 650mm |

| Overall diamension | 1300*1600*2500mm |

Impeller type:

| Double-disc

|

Impeller head power: | 4.0KW |

Belt drive motor: | 0.75KW |

Dust removal system fan motor: | 1.5KW |

Shot lifting system: | 0.75KW |

| Abrasive Flow Rate | 60kg/min |

| The diameter of holes in the tumble belt | 3mm |

Tumble Shot Blasting Machine Applications

Shot blasting performs extraordinary effective for oxide removal, core removal, rounding and other cleaning purposes. The tumble belt blast machine allows processing small parts in batches or big sized objects in cylindrical shape.