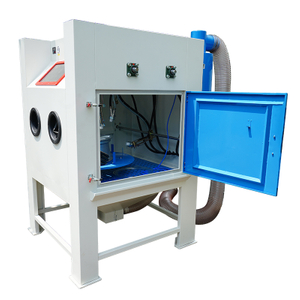

Turntable Sand Blast Cabinet with Automatic Cart

This custom-made automatic sandblasting cabinet is configured with 3pcs of auto guns, a turntable and a cart, achieving high processing efficiency and great labor saving. The specially designed automatic cart is to drive the workparts in and out of the cabinet, which facilitates the operation of heavy workparts.

Automatic Turntable Sand Blast Cabinet Application

Loaded the workparts on the turntable, the cart will automatically drive it into the cabint, as a group of auto guns blasting and oscillating, the turntable rotates automatically at the same time, thus all surfaces and corners of the object can be cleaned thoroughly and evenly. The automatic sand blaster is effective for removing rust and stripping old paints or roughing an adhesive surface before powder coating.

Turntable Sand Blasting Cabinet Features

Automatic Blast Guns

Configured with 3 pcs of automatic blast guns can be adjusted for fixing blasting or oscillating blasting.

The work of each blast gun is individually controlled. You can choose the optimal setting to meet your surface finishing needs. Also can be configured a manual blast gun helps for more precise repair blasting.

Automatic Turntable

The heavy-duty turntable is ideal for loading big and irregularly shaped workpieces, also can be fitted with fixture for handling small and light workparts.

The turntable can be set to automatic rotating working along with automatic guns for increased efficiency and uniformity. While it also can be set for manual operation for more precise cleaning jobs.

Cyclone Separator

The automatic blast machine can be optionally equipped with a cyclone device, which is used to separate ultrafine abrasives from dust, increasing the recycling rate of pure abrasives.

Filter Dust Collector

Each of our sandblasting cabinet is designed with a dust removing system, including a piece of cartridge filter and a set of fan motor. The high-precision filter is made of 100% polyester to absorb even micro dust particulates, which ensures vented airflow back to the workshop is dustfree .

Turntable Sand Blasting Cabinet Specifications

Model: | KF-1212-3A |

Working chamber dimension(L*W*H): | 1200mm*1200mm*850mm |

Power supply: | 220V, 50HZ (voltage can be customized as local) |

Machine light power: | 220V, LED* 2 |

Compressed air source: | 5-7bar(kg/㎡) |

Air flow: | 0.8-3m3/min dry and clean compressed air |

Separator air volume: | 8.5m3/min |

Dust removal method | Cartridge Filter Type |

Blasting Gun Qty | 3 pcs |

Blasting Nozzle | Boron Carbide |

Why choose Kafan Automatic Sandblasting Cabinet?

1. Fully automatic operation reduces labor cost while ensures efficiency and quality consistency.

2. Each cabin style blast machine is configured with filter cartridge dust collector, effectively remove dust from the working chamber, ensure only the clean air is vented to the workshop.

3. Our popular automatic blast machines are widely needed as we sold for many years with proved quality and performance.

4. Support full customization of blasters according to your being finished objects and productivity requirements. We have professional and experiencd technical team to design the custom-built blast machine.

5. Allows customers posting their samples for testing with our automatic sandblasting machines, we have a variety of standard automatic sandblasters suits for different finishing applications.

6. Each blast system is built in-house at our 4000m^2 production base, for necessary quality-control and cost-control.