KF-9080W

Kafan

| Availability: | |

|---|---|

The wet blasting machine works through a pump agitating the abrasive and water into 'slurry' which is then pressurized before delivering out to hit the surface you're treating. The water-based abrave flow removes the unwanted materials and washes them away, thus makes the surface smooth and clean. Our stainless steel made wet blast cabinet features durable, anti-rust and longlife.

Uses a high performance pump that involves the abrasive media mixed with water.

3mm Stainless steel made blast cabinet, features rigid and anti-rust.

Low voltage windscreen wiper and wash facility to maintain visibility throughout

Special wet blasting gun with big diameter boron carbide nozzles for wet blasting process,

Reliable foot pedal controlls the working to increase operation safety.

The granular blasting gloves is skidproof, features more reliable and efficient.

Wet Blasting Chamber

Slurry Pump

Pressure Regulaters

Window Washer

Wet Blasting Guns

Blasting Gloves

| Model | KF-6868W-S |

| Outer size | L680*W680*H1550mm |

| Work area | L600*W600*H500mm |

| Motor | 1.1Kw |

| Air requirement | flow 0.5-1.1m^3/min |

| Light | 1*18w saving lamps |

| Blast Gun | 1 pc of wet blast gun with 1 boron cabide nozzle (4-8mm) |

| Air consumption for 1 gun | 0.4-0.8Mbar |

| Volume of abrasive & water | 25L |

| Suitable abrasive | Glass beads (for aluminum, stainless steel) Brown Aluminum Oxide (stell or other)80#-320# |

| Feed abrasive | 4-6kg |

| Abrasive : Water | 1:3 |

| Voltage | 220V/50HZ (customized) |

| Model | KF-1610W (double gun) | KF-1212W | KF-1010W | KF-9080W |

| Size | 1600 * 1000 * 800mm | 1200 * 1200 * 600mm | 1000 * 1000 * 800mm | 900 * 900 * 800mm |

| Loading | 100-140 kgs | 80-120 kgs | 50-80 kgs | 30-50 kgs |

Other custom sizes pls contact with us!

Vapor blasting finish is produced through flow of water-based abrasive, giving a finer and cleaner finish as the flushing action of the water causes no media impregnated into the workparts.

The bringing of water reduces the dust leaving a clean working chamber and increase the visibility.

Due to the water's cushion, vapor blasting creates gentle but effective force for surface removal, it is more suitable for treatment of delicate art crafts, precise instruments or other high requirement applications.

Water' s buffering action reduce the broken to abrasives, and minimize wear to the equipment, saves production in long term.

The wet blasting machine works through a pump agitating the abrasive and water into 'slurry' which is then pressurized before delivering out to hit the surface you're treating. The water-based abrave flow removes the unwanted materials and washes them away, thus makes the surface smooth and clean. Our stainless steel made wet blast cabinet features durable, anti-rust and longlife.

Uses a high performance pump that involves the abrasive media mixed with water.

3mm Stainless steel made blast cabinet, features rigid and anti-rust.

Low voltage windscreen wiper and wash facility to maintain visibility throughout

Special wet blasting gun with big diameter boron carbide nozzles for wet blasting process,

Reliable foot pedal controlls the working to increase operation safety.

The granular blasting gloves is skidproof, features more reliable and efficient.

Wet Blasting Chamber

Slurry Pump

Pressure Regulaters

Window Washer

Wet Blasting Guns

Blasting Gloves

| Model | KF-6868W-S |

| Outer size | L680*W680*H1550mm |

| Work area | L600*W600*H500mm |

| Motor | 1.1Kw |

| Air requirement | flow 0.5-1.1m^3/min |

| Light | 1*18w saving lamps |

| Blast Gun | 1 pc of wet blast gun with 1 boron cabide nozzle (4-8mm) |

| Air consumption for 1 gun | 0.4-0.8Mbar |

| Volume of abrasive & water | 25L |

| Suitable abrasive | Glass beads (for aluminum, stainless steel) Brown Aluminum Oxide (stell or other)80#-320# |

| Feed abrasive | 4-6kg |

| Abrasive : Water | 1:3 |

| Voltage | 220V/50HZ (customized) |

| Model | KF-1610W (double gun) | KF-1212W | KF-1010W | KF-9080W |

| Size | 1600 * 1000 * 800mm | 1200 * 1200 * 600mm | 1000 * 1000 * 800mm | 900 * 900 * 800mm |

| Loading | 100-140 kgs | 80-120 kgs | 50-80 kgs | 30-50 kgs |

Other custom sizes pls contact with us!

Vapor blasting finish is produced through flow of water-based abrasive, giving a finer and cleaner finish as the flushing action of the water causes no media impregnated into the workparts.

The bringing of water reduces the dust leaving a clean working chamber and increase the visibility.

Due to the water's cushion, vapor blasting creates gentle but effective force for surface removal, it is more suitable for treatment of delicate art crafts, precise instruments or other high requirement applications.

Water' s buffering action reduce the broken to abrasives, and minimize wear to the equipment, saves production in long term.

What is wet abrasive blasting? The benefits and application.

This article will tells you the benefits and application of wet blasting in details,

Dry Sandblasting VS Wet Sandblasting

This article will help you make decision choose a wet blaster or dry blaster according to your products and requirements.

When you buy a wet sandblaster, this article will give your tips about instructions and attensions.

What is wet abrasive blasting? The benefits and application.

This article will tells you the benefits and application of wet blasting in details,

Dry Sandblasting VS Wet Sandblasting

This article will help you make decision choose a wet blaster or dry blaster according to your products and requirements.

When you buy a wet sandblaster, this article will give your tips about instructions and attensions.

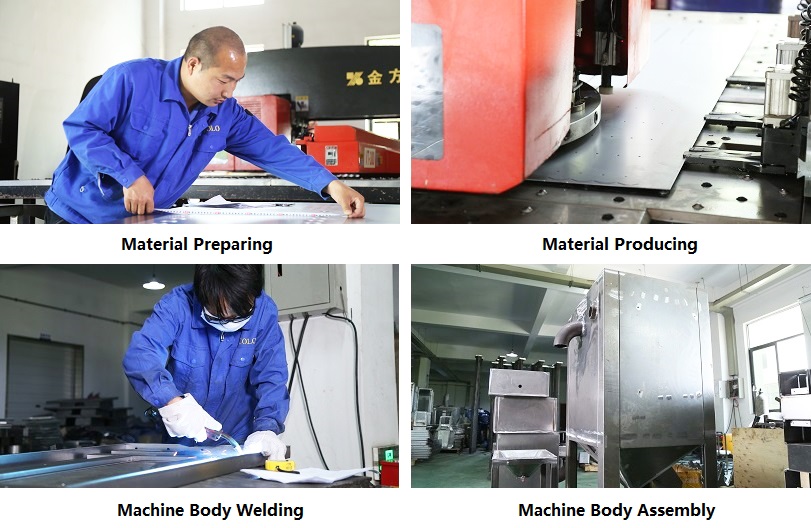

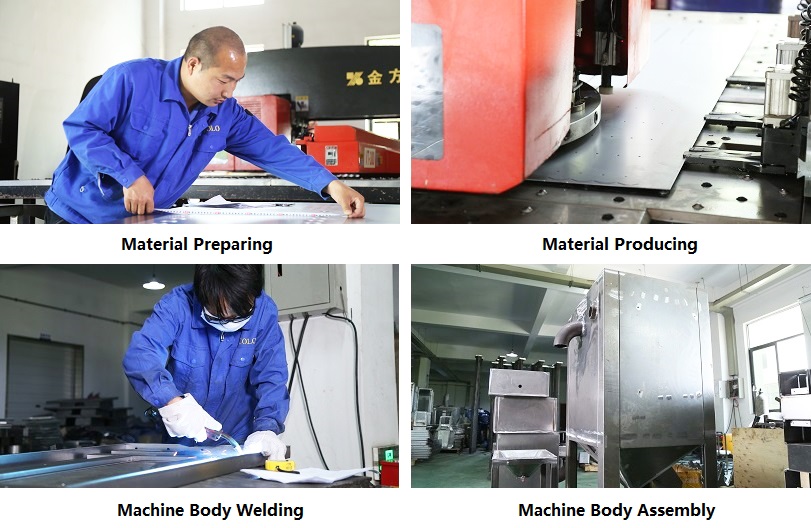

Located in Hangzhou, China, we we own a manufacturing base of 3600 square meter, around 100 employees and 24 sets production equipment, dividing into technical department, sales department, after-sale department, production department, QC department, manage and finance department, etc. As a fast growing company in supplying sandblasting equipment and mass finishing equipment, we devoted all ourselves to offering solution for any surface finishing problems.

All sand blasting machines were made in house by rich experienced production team of Kafan. To pursue best performance, each blast machine body is steel plate welded with powder coated surface, durable, wear-resistant and long lifespan, and the main components are famouse European brand imported, by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.

Our products can be divided into two main parts, sandblasting equipment and mass finishing machines.

Sandblasting equipment including: manual sandblasting machine, suction sand blast cabinet, pressure blasting machine, wet abrasive blasting equipment, portable blaster pot, automatic conveyor blast system, tumbler blaster, rotary table blast machine, crawl blast machine.

Mass finishing system including: vibratory polishing & deburring bowl, vibratory bowl with separator, centrifugal barrel tumbling machine, centrifugal disc finishing system, mass finishing media.

We offer service: Standard Production Models, Customized Design, Before-order Technical Support, Engineer Oversea Installing & Training, Free Sample Testing, 24 hour On-line Consulting, ODM, OEM.

Located in Hangzhou, China, we we own a manufacturing base of 3600 square meter, around 100 employees and 24 sets production equipment, dividing into technical department, sales department, after-sale department, production department, QC department, manage and finance department, etc. As a fast growing company in supplying sandblasting equipment and mass finishing equipment, we devoted all ourselves to offering solution for any surface finishing problems.

All sand blasting machines were made in house by rich experienced production team of Kafan. To pursue best performance, each blast machine body is steel plate welded with powder coated surface, durable, wear-resistant and long lifespan, and the main components are famouse European brand imported, by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.

Our products can be divided into two main parts, sandblasting equipment and mass finishing machines.

Sandblasting equipment including: manual sandblasting machine, suction sand blast cabinet, pressure blasting machine, wet abrasive blasting equipment, portable blaster pot, automatic conveyor blast system, tumbler blaster, rotary table blast machine, crawl blast machine.

Mass finishing system including: vibratory polishing & deburring bowl, vibratory bowl with separator, centrifugal barrel tumbling machine, centrifugal disc finishing system, mass finishing media.

We offer service: Standard Production Models, Customized Design, Before-order Technical Support, Engineer Oversea Installing & Training, Free Sample Testing, 24 hour On-line Consulting, ODM, OEM.

content is empty!