Intelligent Automatic Sandblasting Cabinet

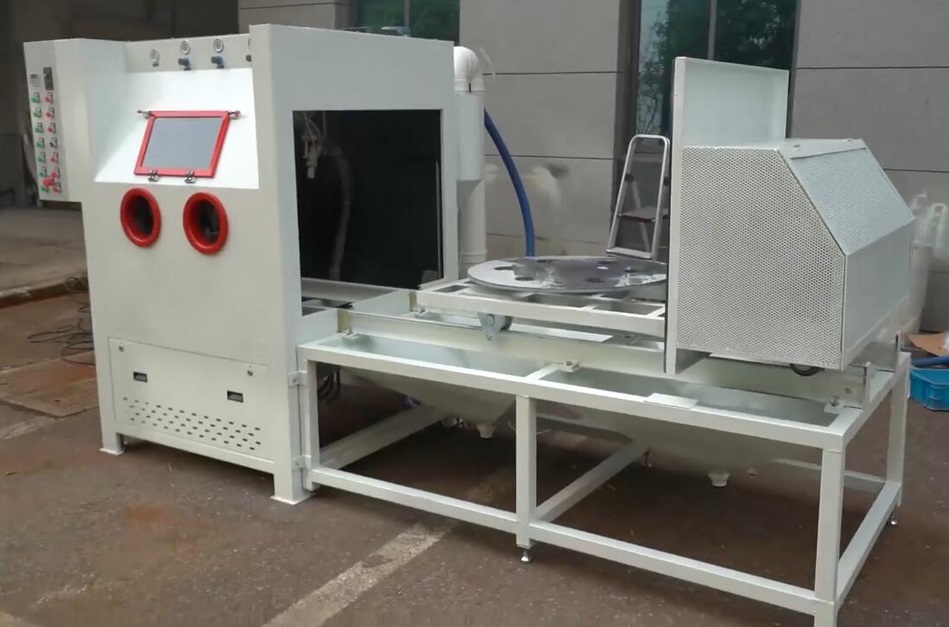

This is an intelligent sandblasting cabinet developed by Kafan which applies to any blasting requirements with great efficiency and flexibility.

From manual to fully automatic with multiple moving guns and flexible work turntable, whether for heavy wheels, small cylinders or complexs shaped moulds, this blasting cabinet provides full-scale and uniform surface finishing effect.

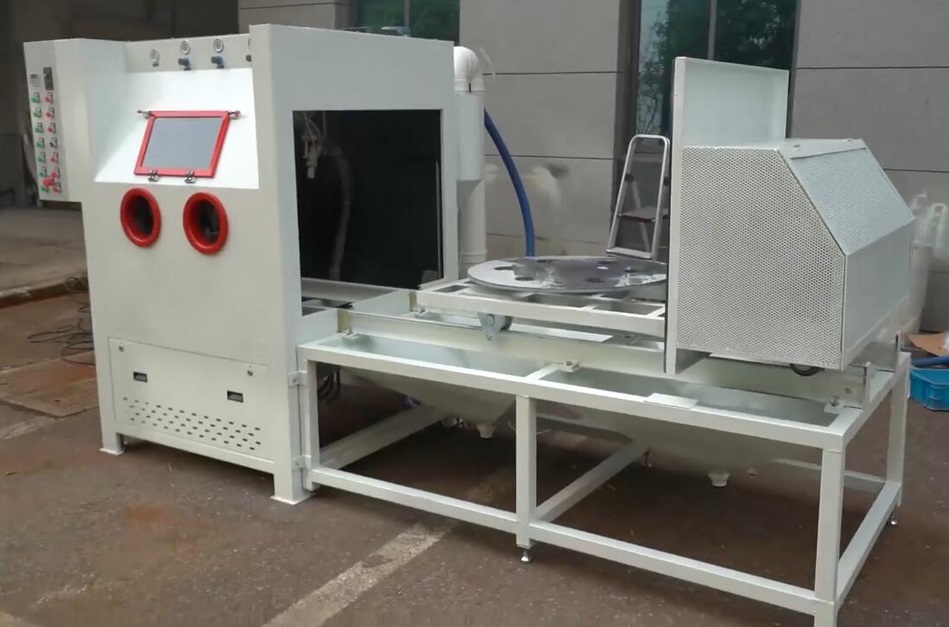

Multi-functional Sandblasting Cabinet for Both Manual and Automatic Application

It realizes flexible switch of Manual and Automatic operation to meet different finishing requirements, through blast gun settings, turntable settings, blasting time settings.

Manual Operation Mode: Using the manual gun and manually rotating the turntable, you can sandblasting more meticulously.

Automatic Operation Mode: Pre-set all parameters on PLC, it achieves automatic gun blasting, turntable rotating, dust collecting. The machine will automatically stop when time arrives for a efficient, unmanned process

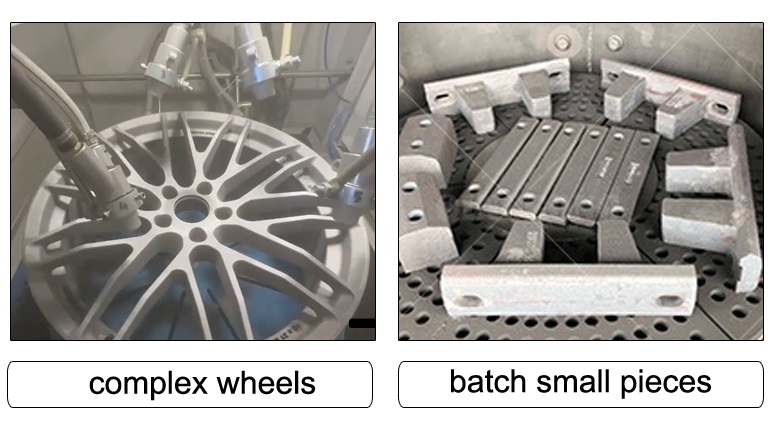

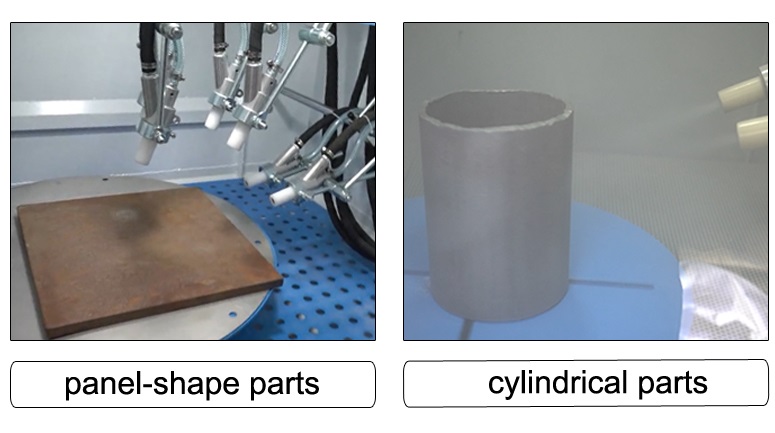

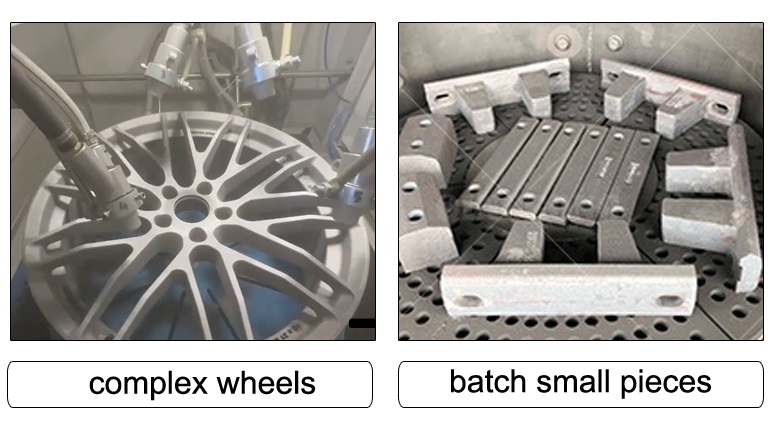

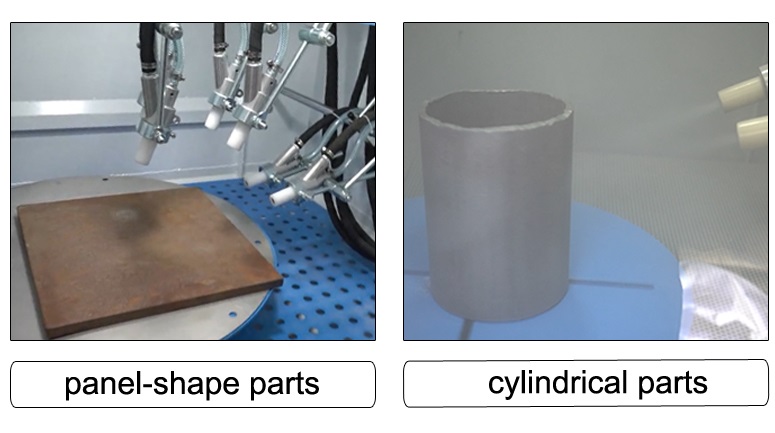

Multi-functional Automated Sandblasting Cabinet Applications

This blasting cabinet has a wide application for a diversity of workparts, such as alloy wheels, small pieces, cylindrical and panel shaped parts, with a group of oscillating guns blasting abrasives from multi-dimensional directions, it provides more precise and uniform cleaning, and effectively stripping old paints, rust, or roughing an adhesive surface.

Flexible, Precise Sandblasting Cabinet Suits Different Parts' Sizes, Shapes

1 piece manual gun, a group of automatic guns, each blast gun is individually controlled for saving medias

Designed with a flexible fixture on the turntale to fix objects in different sizes

The automatic gun group can be set for fixed blasting or oscillating blasting with adjusted angles, appropriately handling different shaped objects.

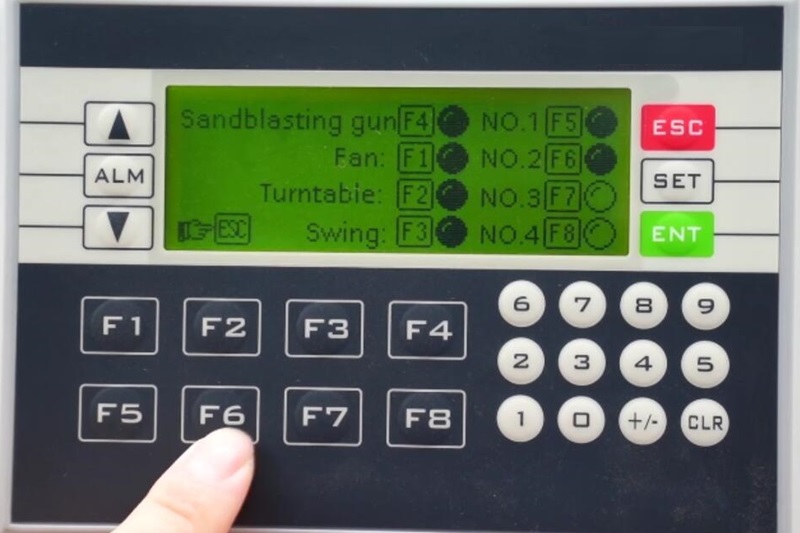

Applies PLC system achieving a reliable, easy-to-control, fully automatic process.

Embedded glass window facilitates operators observe the blasting process at any time.

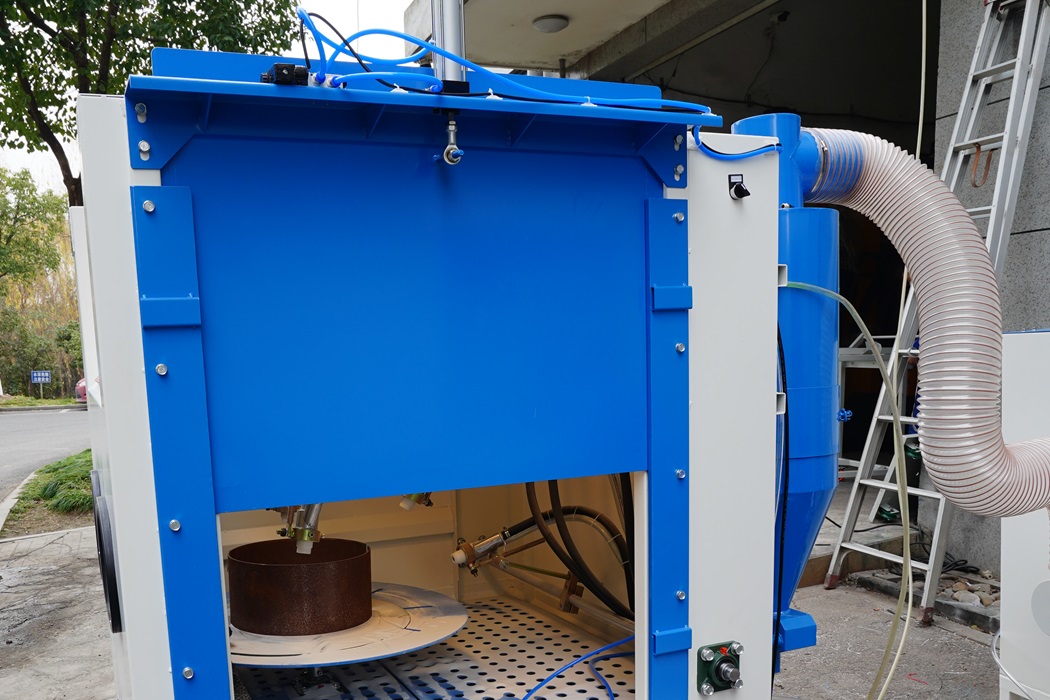

Enclosed cabin design with cyclone and filter dust collector provides an environmental-friendly workshop.

Intelligent Automated Sandblasting Cabinet Features

Manual & Automatic Blast Guns

Configured with a group of automatic blast guns and 1 piece of manual gun, the automatic blast guns can be adjusted for fixing blasting or oscillating blasting, and quantity is customized.

The work of each blast gun is individually controlled via PLC. You can choose the optimal setting to meet your surface finishing needs. A manual blast gun helps for more precise repair blasting.

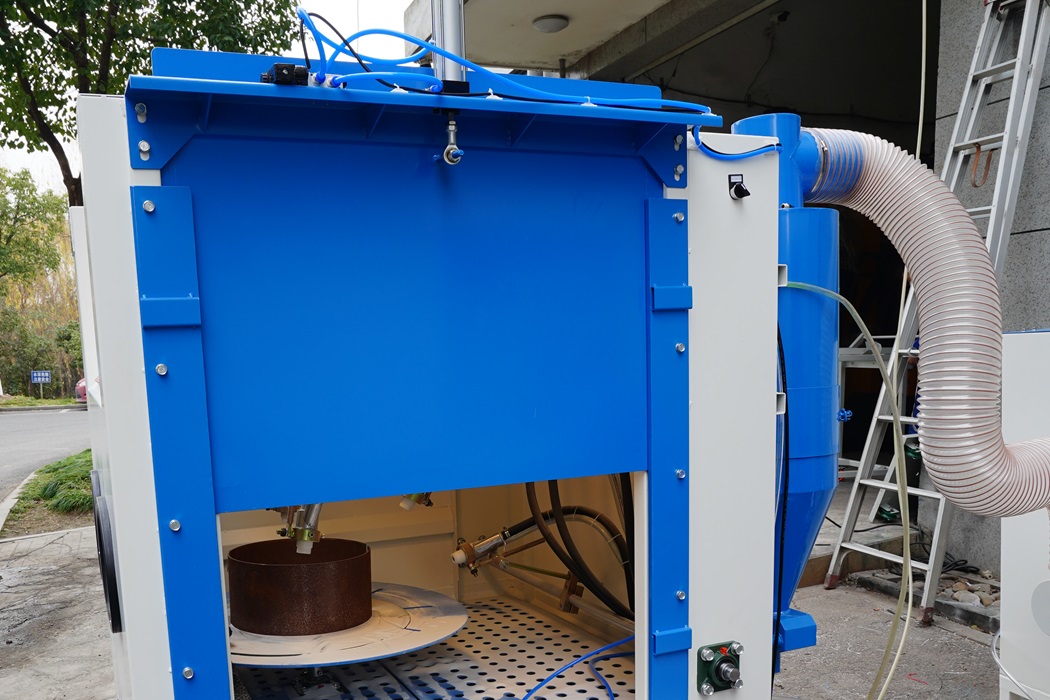

Automatic Turntable with Fixture

The heavy-duty turntable is ideal for loading big and irregularly shaped workpieces, fitted with fixture for handling small and light workparts.

The turntable can be set to automatic rotating working along with automatic guns for increased efficiency and uniformity. While it also can be set for manual operation for more precise cleaning jobs.

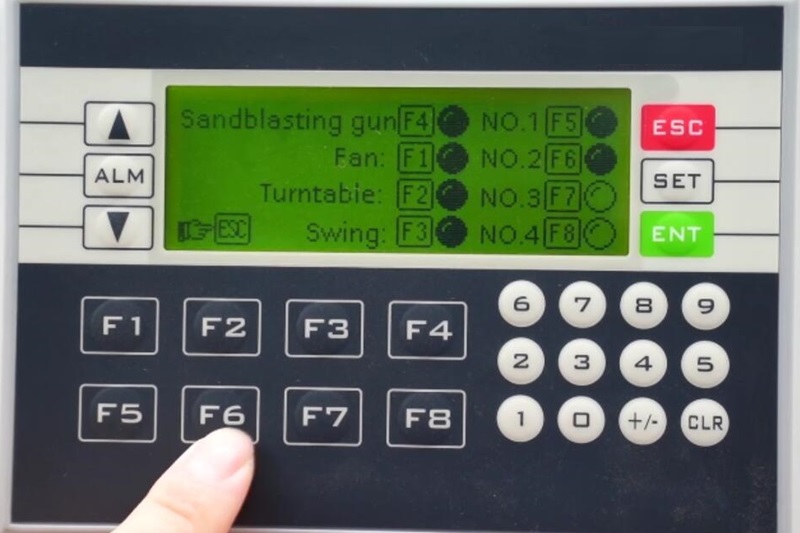

PLC Control

Through the PLC advanced system, you can easily control the work of each blasting gun, blasting time, turntable rotating, dust collector working. To achieve a fully automatic process, you can preset all working parameters on the panel, once the preset time has arrived, the machine will stop working immediately.

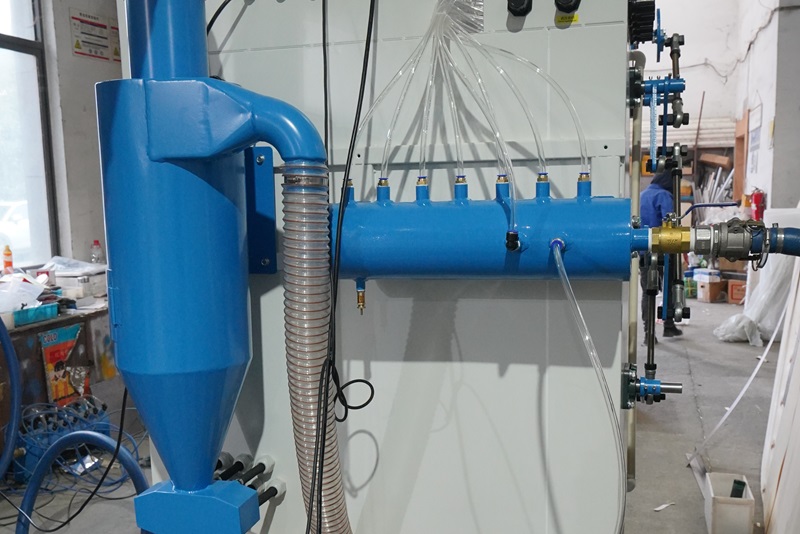

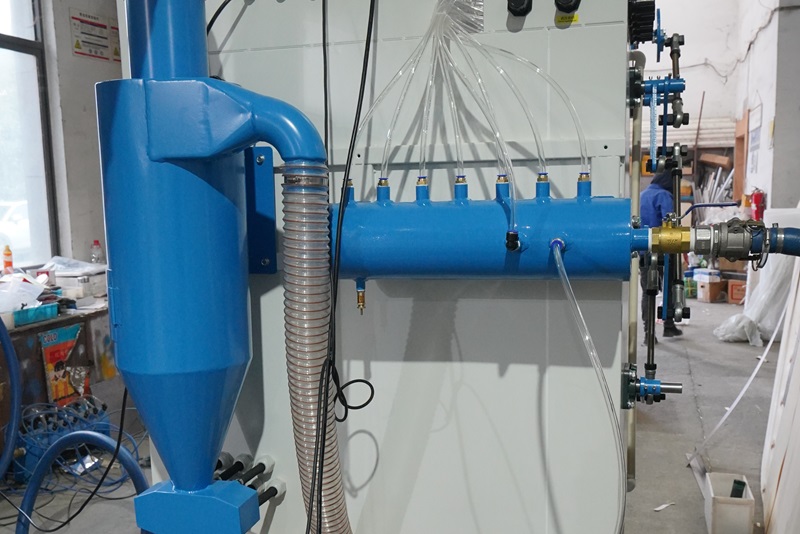

Cyclone Separator

The automatic blast machine can be optionally equipped with a cyclone device, which is used to separate ultrafine abrasives from dust, increasing the recycling rate of pure abrasives.

Filter Dust Collector

Each of our sandblasting cabinet is designed with a dust removing system, including 2 pieces of cartridge filter and a set of fan motor. The high-precision filter is made of 100% polyester to absorb even micro dust particulates, which ensures vented airflow back to the workshop is dustfree .

Automatic Door (optional design)

The automatic sand blasting cabinet can be designed with an automatic opening/shutting door controlled to facilitate your operation

Automatic Cart (optional design)

The sandblasting cabinet can be added with an outside cart for easy loading and unloading of heavy workparts, the cart can be designed for automatically driving the workparts in and out of the cabinet, which further facilitates the operation

KF-1212-4A Automatic Sandblasting Cabinet Specificatios

Model: | KF-1212A-4A |

Working chamber dimension(L*W*H): | 1200mm*1200mm*850mm |

| Qty of Blast Gun | 4pcs auto gun, 1pc manual gun |

Power supply: | 220V, 50HZ (voltage can be customized as local) |

Machine light power: | 220V, LED* 2 |

Compressed air source: | 5-7bar(kg/㎡) |

Air flow: | 0.8-3m3/min dry and clean compressed air |

Separator air volume: | 8.5m3/min |

Dust removal method | Cartridge Filter Type |

kafan is a professional manufacturer with great design capability and a wealth of customization practice with over 10 years experience. Pls feel free to contact us for any surface finishing requirments.