Tumble Belt Automatic Sandblasting Machine

This automatic sandblasting machine allows parts tumbling on a thick, perforated rubber belt, a group of blast guns uniformly blast medias to all exposed surfaces to deliver a consistent finish.

Tumble belt type sandblasting machine is ideal for batch processing big quantity of small pieces at once, as well as relatively heavy, complex-shaped parts that would be hard to handle in a traditional manual blast cabinet

How Automatic Tumble Blasting Machine Works

Simply load parts on the rubber belt and set the timer, then return later to unload, you will get perfectly cleaned or finished parts. Nozzles are mounted on an oscillating blast guns to ensure maximum coverage of all parts. the oscillating speed and amplitude can be adjusted to address all process constraints and for optimal results and productivity.

Automatic Tumble Sandblasting Machine Features

Rubber Belt & Automatic Guns

1) Thick, perforated rubber belt with a loading capacity of 200kgs.

2) The endless rubber belt keeps parts gently tumbling as they are exposed to a group of oscillating blasting guns, which ensures abrasive flows cover all surfaces.

3) Each blasting gun is composed of boron carbide nozzles, which is the most durable material in the market.

4) The blast guns quantities can be tailored to suit your actual production needs.

Electric & Pneumatic

1) It is an easy system to control the working of each blast guns, as well as adjust belt tumbling speed at the side cabinet, set blasting cycle time and start/stop dust collector,

2) The air pressure of each blast gun can be flexibly regulated by pressure valves at the front of the machine with clear gauges.

Sandblasting Dust Collector

1) Configured pulse filter cartridge unit for dust removal system, features high removal efficiency and requires easy installation and maintenance.

2) Can be optionally equipped with cyclone separator for increased recycling of ultra-fine abrasives from dusts.

3) Closed cabin design with dust collector, keeps your workshop clean.

4) Compact design and easy maintenance.

Automatic Tumble Belt Automatic Sandblasting Cabinet Specifications

Model

| KF-A40

|

Working cabinet: | L600*W500*H500 (mm) |

Cabinet outsize: | L800*W650*H2720 (mm) |

Dust collector dimensions: | L800*W800*H2100mm |

Productivity:

| 0.3-0.5 T/H |

Load capacity: | ≤100KGS |

Rolling motor power:

| 1.5KW |

Dust collection motor power:

| 2.2KW |

Automatic blasting gun: | 4pcs Aluminium alloy blasting guns, with 4pcs boron carbide nozzles, dia 8mm. |

Voltage: | 380V 50HZ |

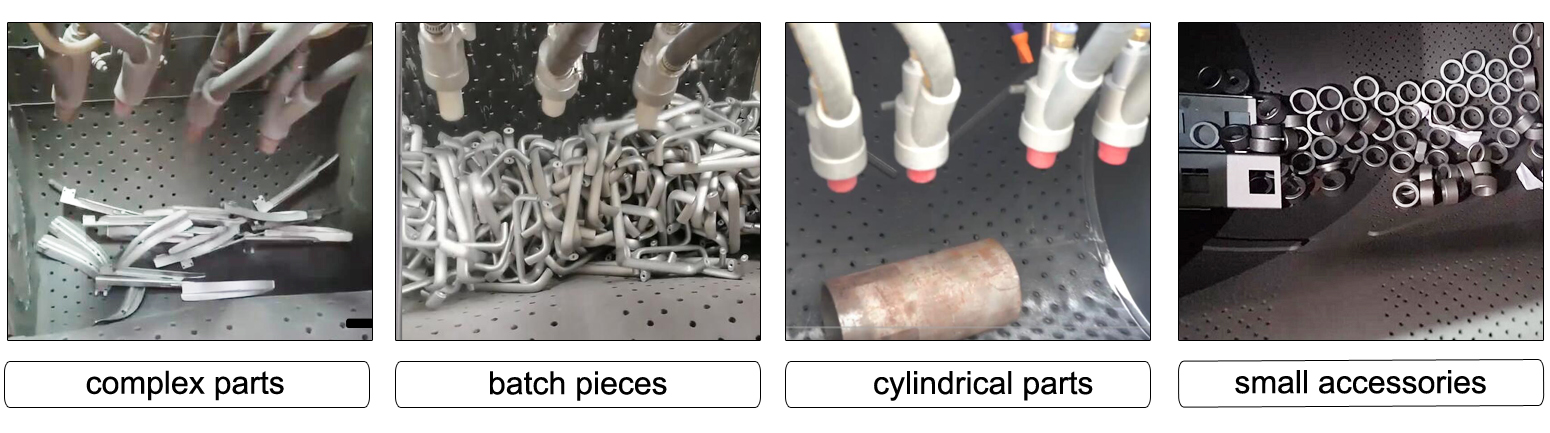

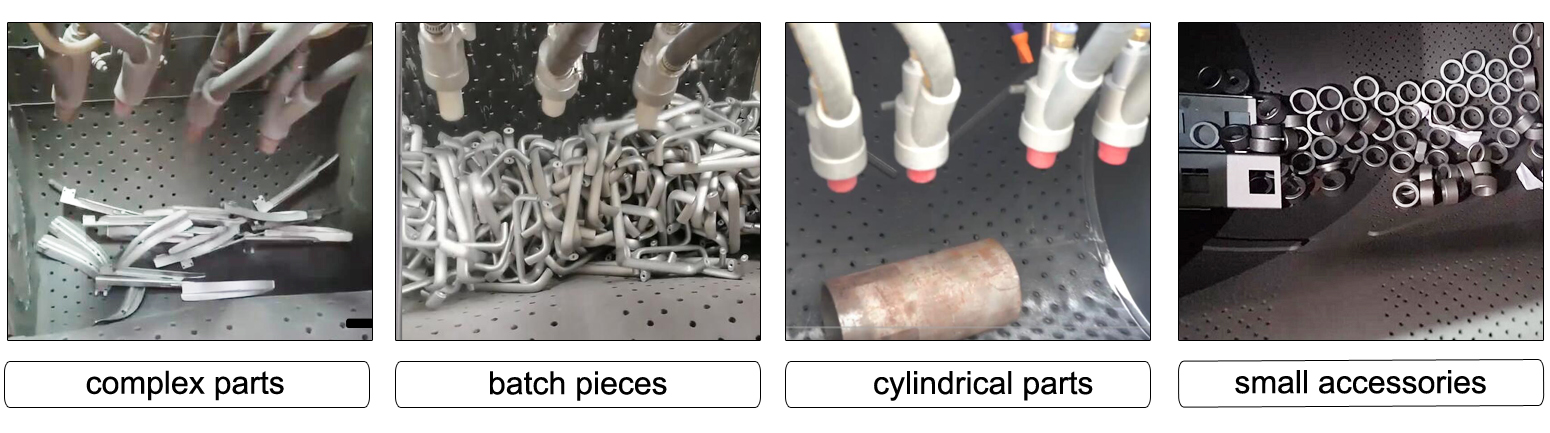

Tumble Belt Automatic Sandblasting Cabinet Applications

Tumble belt blasting machines are highly-efficient batch surface treatment equipment, which are best suited for small dimensional, regular-shaped metal workpieces that are not easily broken or tangled. These types of workpieces fully utilize the continuous, automatic, and batch processing advantages of the tumble sandblasting machines.

1. Small stamped parts, die-cast parts

Screws, nuts, bolts, washers, springs, small hardware, small automotive parts, electronic components, zinc/aluminum die-cast parts, etc.

Reasons: Small size, light weight, and able to tumble at the belt ensures that all surfaces are evenly blasted.

2. Regular-shaped parts that can tumble

Small or medium sized barrels, golf club heads, valve parts, gears, cutting tools (such as drill bits, milling cutters), etc.

Reason: The relatively regular shape, without deep holes or complex internal cavities, prevents them from jamming or snagging during tumbling, ensuring thorough sandblasting without blind spots.

3. Parts requiring removal of surface oxide scale, burrs, and rust

Heat-treated parts (oxide scale removal), machined parts (burr removal), forgings, and castings (rust removal).

Reason: Tumble sandblasting machines provide uniform impact force, efficiently cleaning these unwanted layers.