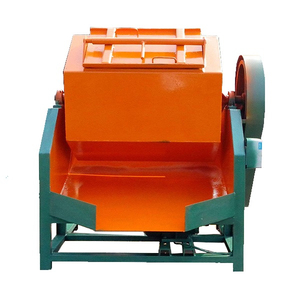

Barrel Tumbling Machine for Sale

Tumbling barrels are the most versatile option of parts finishing systems. Reasons of application for this equipment include heavy deburring, high polishing, degating, and parts cleaning.

Barrel Tumbling Machine Configurations

1. Barrel is locked with a simple cover and cam system, which is easy to open and close while ensues safety.

2. A specially designed discharging slope fully empty the barrel as well as facilitates the operation cycles.

3. With controller to monitor the whole process, as well as switch to operate the discharging after complete the polishing.

4. Can be applied with ffrequency adjustable motor to multiple cleaning and burnishing requirements while ensures the running stability.

Barrel Tumbling Machine Features & Advantages

1. The tumbling action of the entire load on the barrel produces uniform and even surface of parts while can not achieved by hand.

2. The tumbling equipment using parts and media grinding is an environment-friendly mass finishing solution with low noise.

3. With perfect polishing and deburring results, the barrel finisher is can operates a variety of metal or non-metal parts in batches, improving working efficiency 5-10 times.

4. Variable speed control allow these finishing machines to achieve whatever finish you desire, from a simple polish at low speed, to full scale deburring and edge radiusing.

Barrel Tumbling Machine Specifications

| Model | Capacity (L) | Barrel Size(mm) | Motor Power (kw) | Speed (r/min) | Weight (kg) |

| KF-50 | 50 | 40*45 | 0.75 | 33-39 | 100 |

| KF-100 | 100 | 50*50 | 1.1 | 33-39 | 150 |

| KF-150 | 150 | 60*60 | 1.5 | 33-39 | 200 |

| KF-200 | 200 | 65*65 | 2.2 | 33-39 | 250 |

| KF-300 | 300 | 65*100 | 3 | 33-39 | 350 |

| KF-400 | 400 | 70*100 | 3 | 33-39 | 400 |

| KF-500 | 500 | 90*100 | 4 | 33-39 | 500 |