-

Q how to polish metal to a mirror finish by vibratory finishing equipment

A Question from user

:What is the difference between a vibratory polisher and a magnetic polisher and a barrel polisher?

Can the workpiece be polished into a mirror finish?

All three vibratory finishing machines can get what kinds of finishing ?

Vibratory polisher, magnetic polisher, and barrel polisher and all types of other polishers.

Adding brighteners and polishing particles inside can make the mirror surface, but the mirror effect is very poor

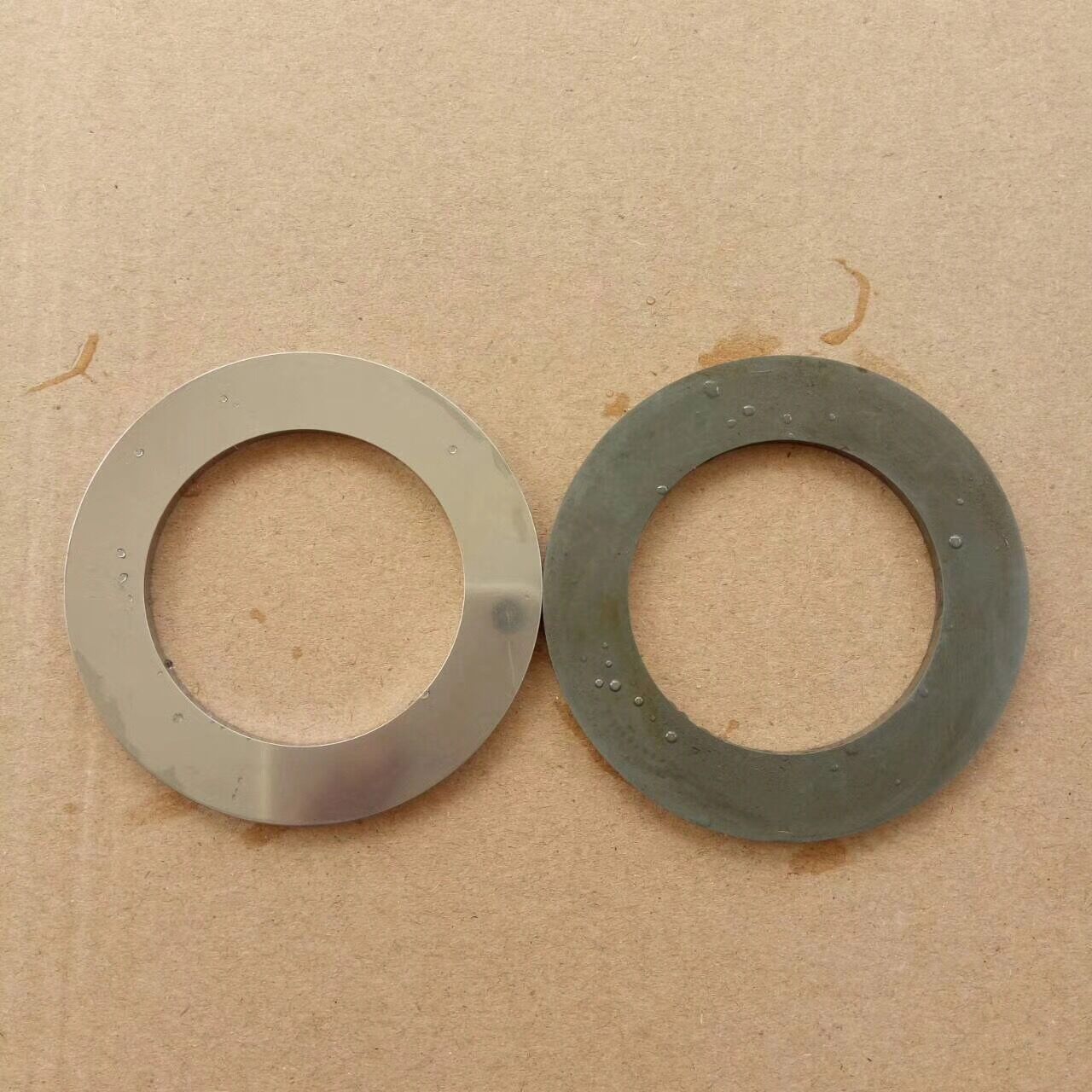

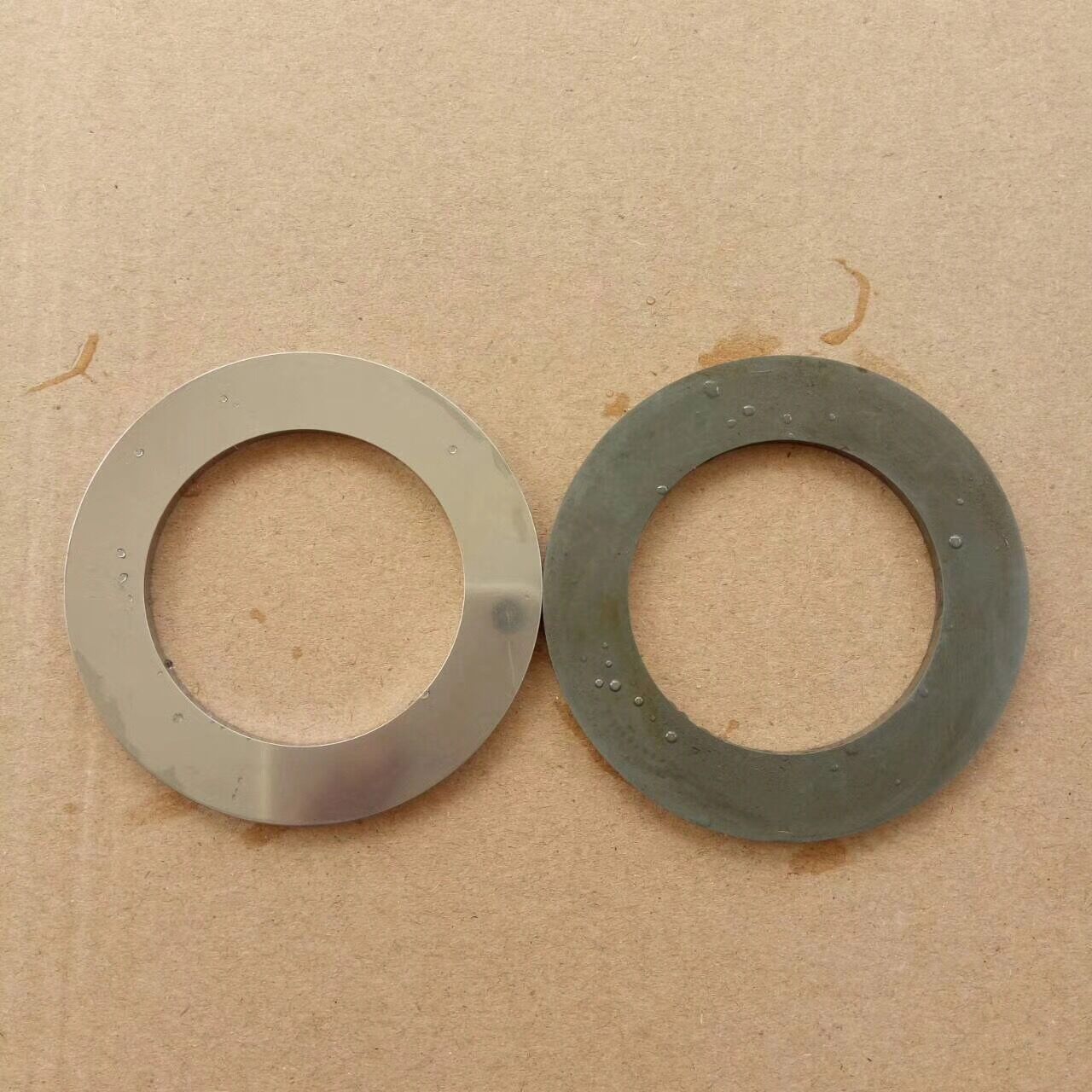

below is some photos of producted after polished for your reference

-

Q how to remove burrs by spiral vibratory finishing machine?

A If you need to remove burrs by vibratory finishing machine

The following things are needed

1), Tumbling Media for Barrel and Vibratory Finishing Equipment

Brown Aluminum Oxide Grit is usually inclined triangular, triangular or round ball shape,

and more suitable for iron, stainless steel, plastic grinding is usually conical, more suitable

for aluminum alloy, zinc alloy softer material needs to be based on the product Select the

type, shape, specifications.

2), liquid mass finishing compounds for vibratory finishing systems.the grinding fluid,

according to the general use of iron material grinding fluid is alkaline, and other materials

used cleaning machine is acidic.

3): The volume ratio of product and abrasive is generally: 1 : 2.5 -

Q What are the differences of Barrel Finishing Machine, Vibratory Equipment and Centrifugal system?

A Barrel FInishing Machine usually remove heavy burrs, smooth sharp edges and round corners in effective cycles, but does not ideal to touch recesses.

Vibratory Finishing Equipment, perfect to create uniform and even surfaces by removing light burrs or scales, easily reach cavities and corners, Best choice for operating fragile and sensitive parts.

Centrifugal Tumbling System by using centrifugal force produces high grinding action for any polishing and deburring requirements, as well as in much shorter cycles while barrel tumbling can not beat.

-

Q What is tumbling finishing?

A Tumble finishing is technique of mass surface finishing for smoothing or deburring a rough surface on quantities of small parts.

-

Q What is surface finishing?

A Surface finihsing is a broad range of processing industry, making the manufactured items in required surface quality, such as sandblasting to removing rust and degrease before painting or powder coating, deburring and polishing to make workparts surface smooth and bright.

-

Q What is the polishing agent used for?

A 1, Enhance the tumbling and polishing effect.

2. Degreasing, cleaning.

3. Anti-rust and keep bright.

4. Lubricating, decrease the wastage of tumbling media.

5. Soften the liquid quality.

6. Soften the surface oxidation film.

The selection of polishing agents is mainly based on workparts material and the application.

-

Q How to choose right polishing media?

A There are 3 factors for refering to choose right polishing media and the proportion of media and workparts:

1. Shape: Polishing media manufactured in special shapes is to match different shapes of workparts, such as corners, holes, which required to be in good effect and avoid clipping into the workparts.

2. Material: the choice of polishing media material depends on the material and hardness of the workparts.

3. Delicacy: depends on the surface roughness before processed and required delicacy after processed.

-

Q Tumbling Media – Types and Choices

A 1, Ceramic Tumbling Media: has aggressive cutting force which is recommended for general purpose polishing, heavy, middle, light grinding and supports for hard metals

2 Plastic Tumbling Media: applicable for soft materials, like zinc, aluminu, copper or other alloy parts, fast and heaving cutting, geneally remove the burrs of the metal surface and produce a very smooth finishing but with very little shine.

3. Metal Polishing Media: mainly use steel, stainless steel as media, without cutting force, is recommended for the burnish of metal parts.

-

Q What's the benefit of mass finishing?

A As the equipments is available to process workparts in mass automatically and continuously, we can offer the optimum finishing solution for your demands.Manufacturers in a variety of industries get benefited from such method,

1. finishing media can be recycled, save the material cost

2 does not cause pollution on the environment.

3. reduce processing times

4. greatly enhance the working efficiency.

5. good polishing effect on surface

-

Q What is mass finishing?

A Most manufactured products require some surface improvement to ensure that they are in an good condition for the end-users. Mass finishing enables large quantities of products to be finished simultaneously and automatically.

The mass finishing equipment such as vibratory polisher, barrel finisher, centrifugal tumbling machine.