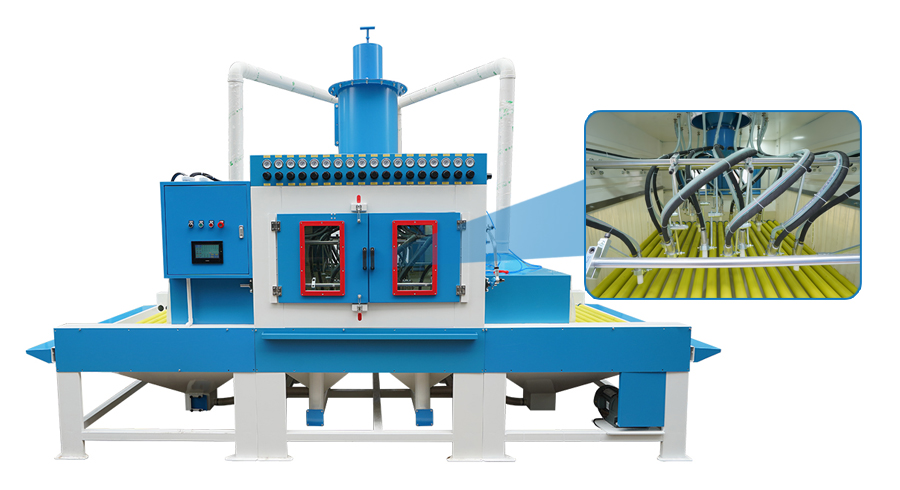

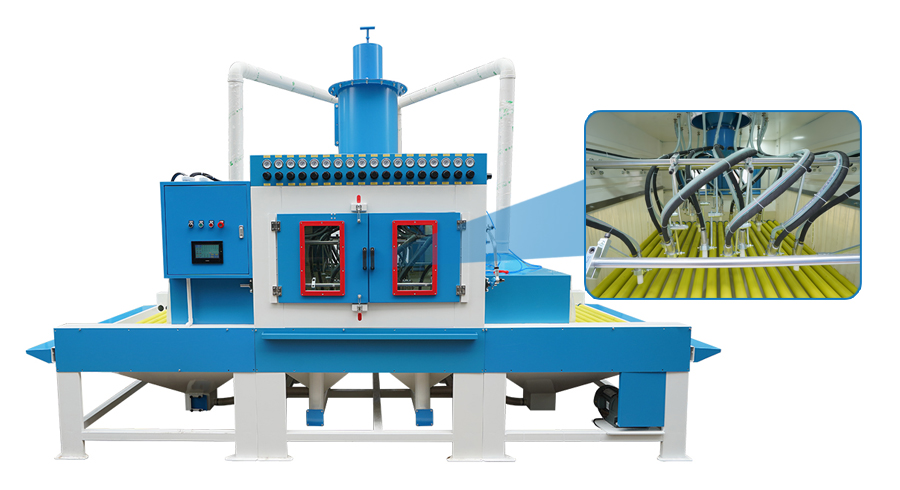

Automatic Sandblasting Machine with Roller Conveyor

The roller conveyor type automatic sandblasting machine handles everything from stainless steel sheets, glass panels, stone panels, and baking trays to heavy structural parts, profiles, pipes, beams, etc.

Heavy-duty roller conveyors help to move those parts to the sandblasting station for finishing, cleaning, rust-removing or paint removing, achieving high productivity and consistent finishing quality

How roller conveyor automatic sandblasting machine works?

During the cleaning process, the electrically controlled roller conveys the parts into the blast working room, and all sides of its body are hit and cleaned by abrasives flow from different coordinate positions, making the oxide scale, old paints or unwanted layer quickly fall off, and the surface of the workparts has a certain roughness and hardness.

Roller Conveyor Automatic Sandblasting Machine Features:

Automatic Blast Guns

Workparts are conveyed to the sandblasting area where they are processed by a group of automatic guns. Each blast gun is individually controlled for working by demands. Depending on the parts' shapes and dimensions, the automatic guns can be set for fixed blasting or oscillating blasting with adjustable angles.

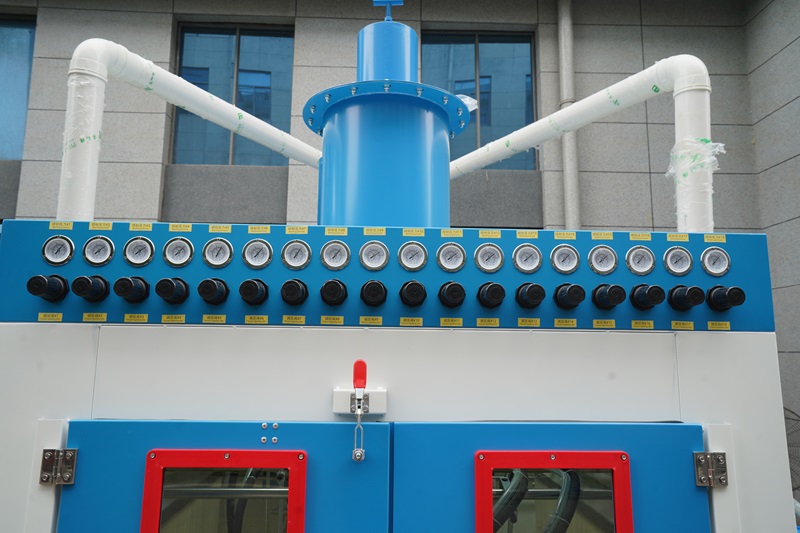

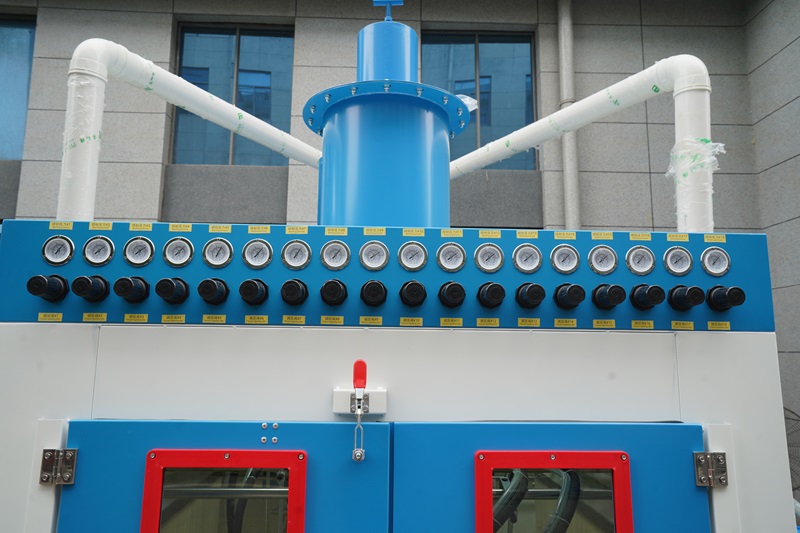

Air Pressure Regular of Each Gun

The air pressure for each blast gun is individually regulated by valves on the front of machine body. It is easy to operate and monitor. Each blast gun requires air pressure of 3-8bar(kg/cm2)

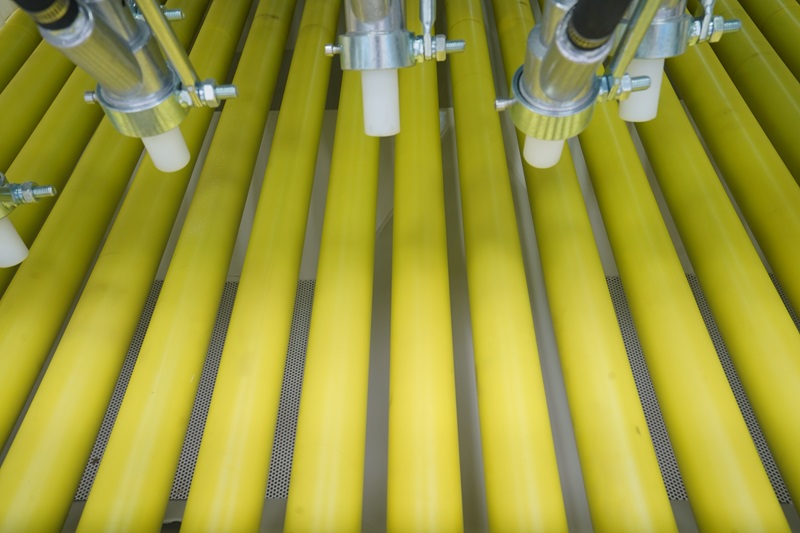

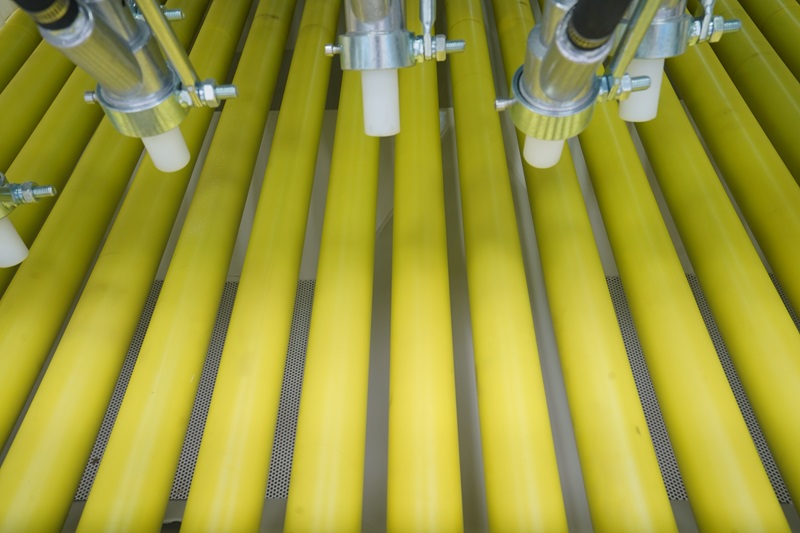

Roller Conveyor

The conveyor motor is controlled by frequency converter, whose speed can be steplessly regulated by inverter within the range of 0 ~ 5m/min. The stainless steel roller type conveyor is specially designed for loading and moving heavy workparts, such as steel beams, tubes, pipes, etc. It is wear-resistant and corrosion resistant.

PLC Control with Touching Screen

The sandblaster applies advanced PLC electric control system, with a high degree of flexibility and stability. The touching screen offers user-friendly interface to manage the blasting and the dust removing process. High automation guarantees the balanced uniform blasting effect, as well as safe production

Dust Removing & Media Recycling

Designed with cyclone separator for effectively separation of abrasives from dusts. Along with an independent cartridge filter dust removal system with excellent effect of dust extraction and ventilation, Blast-removed dust particles are exhausted to the dust collector while blast media is collected at the bottom of the cabinet, then returned to the storage hopper for further use.

Roller Conveyor Automatic Sandblasting Machine Specifications

| Model | KF-4622-28A |

| Working Cabinet Size | L1500 * W2180 * H1000 mm |

| Pass Thru Size | W1900*H300mm, |

| Overall Size | L4640 * W2200 * H2034mm

|

Total Power

| 7.8kw |

| Dust Collector Fan Motor | 7.5kw |

| Loading of Conveyor | 500kgs |

| Conveyor Speed | 0-5m/min, adjustable |

| Drive of Conveyor | 0.4kw speed adjustable |

| Gun Clamp | Automatic swing,

speed adjustable

Power 400W |

| Blast Gun QTY | 28pcs |

| Blast Nozzle | Durable boron cabide material |

| Compressed air Requirements | 35CFM/Per Gun 3-8bar(kg/cm2) |

| Body Material | Cold rolled steel plate |

*The dimension and blast gun quality and other parameters can be customized as requests.

Why Choose Kafan Automatic Sandblasting Machines?

1. High productivity and automation, reduced labor and time.

2. Batch processing increase quality consistency, avoids the uneven blasting effect, chromatic aberration and quality problem.

3. The blasting machine can be designed according to workparts of different sizes, different shapes and different finishing requirements.

4. Each sandblaster is made of durable steel materials with coated surface, and built with quality imported components, which maximize working performance.