About installation, testing, training

Q: I understand that this machine is easy to install and use. However, I have some questions about the installation, testing, and training, do you need to send staff to associated with them? And what is the additional cost?

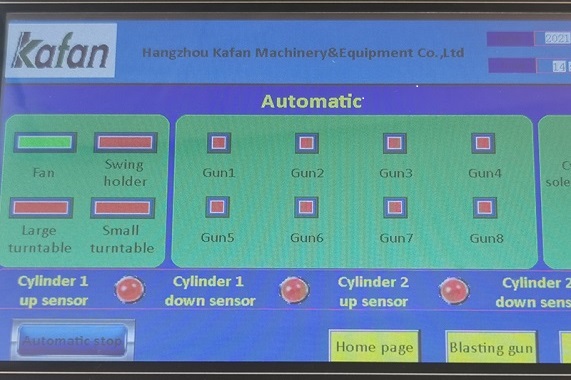

A: We will debug and test the machine well before shipment, the cabinet and dust collector are assembled for shipment. When you receive the package, you just need to connect the cabinet and dust collector by pipes. Then, prepare appropriate power source and air source, place the machine at flat ground of interior space, it can be started.

For testing and training, We provide clear videos, user manuals, layout drawings circuit diagrams, etc. All our clients can manage to work the machine well after getting guidance from us.

We can provide online training, this is free. Assigning engineers to your site is also available, there is additional cost. Their salary is USD150 per day, and the tickets, food and hotel for them are also borne by clients.

About abrasive media

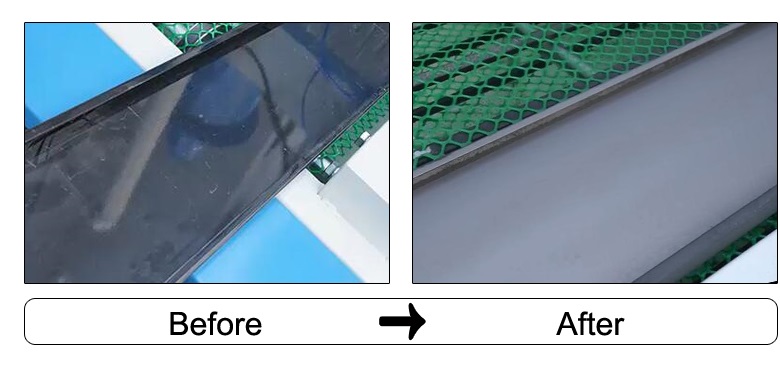

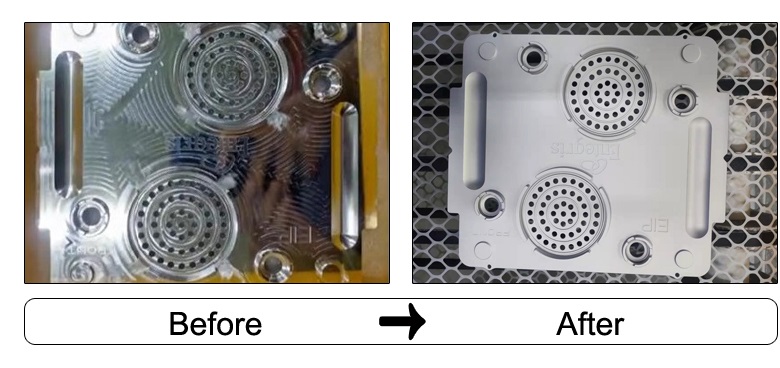

Q: What abrasives can be used if sandblasting stainless steel parts by this machine?

A: As usual, to blast stainless steel, there are three common options of abrasives for using, glass beads, brown aluminium oxide and white aluminium oxide. All three can treat the parts with good finishing. The difference is processing speed and the objects’ surface brightness.

Q: About the blast material, why "brown aluminum oxide”for stainless steel is more recommended , why not glass bead media or stainless steel grit/ball?

A: Brown aluminum oxide is more suitable, because stainless steel grit/ball is little harder and may bring scratches on the surface, glass bead media can also be applied, but spot welding removal speed by glass bead is slower than brown aluminum oxide.

Q: About the abrasive material, such as brown aluminium oxide, for a work cycle of 8hours/day, what is the consumption value for this automatic blasting machine?

About abrasive consumption, if 16 guns work at the same time, it will consume about 70KGS each 8 hours.

About machine working

Q: What is the maximum speed of the conveyor and how about the blasting width of each gun?

The max. conveyor speed is about 2m/min. Each gun' s blasting area is about 25-30cm

Q: What's the air consumption of the this automatic sandblasting machine?

A: About 1m³/min for each gun, and 8 bar of pneumatic pressure line.

Q: Is it possible to adjust the air pressure of blasting?

A: The air pressure of blasting can be adjusted by valves on the front panel. One valve control one blasting gun and can be adjusted independently.

Q: How thick is the steel plates for blasting machine chamber?

A: The steel plates for machine chamber is 2.5mm. It is strong enough to be resistant against collision of abrasive medium.

Q: Chamber sealing against dust is very important for us. Are there any options in your product to protect against environment against dust?

There are rubber strips for well sealing at the door area.

Q: Is it possible to decrease the work sound of machine?

A: Soundproof cotton can be used around the fan motor to decrease the noise of machine.

Q. What are the consumables of the conveyor sandblaster?

A: The blast gun nozzles, rubber hose, abrasive media, and the dust filters.

About sample testing

Q: Is there a possibility for us to send a sample to your company and give us a test of the equipment?

A: We are glad to test the sample for you. Our information for receiving is: Hangzhou Kafan Machinery & Equipment Co.,Ltd

Factory address: Building 34th, Shunfeng Road NO.536, Tangqi Town, Linping District, Hangzhou City, Zhejiang Province, China

Recipient: Skye Wang / Mobile: 0086 133 5719 2103 / Zip code: 311106