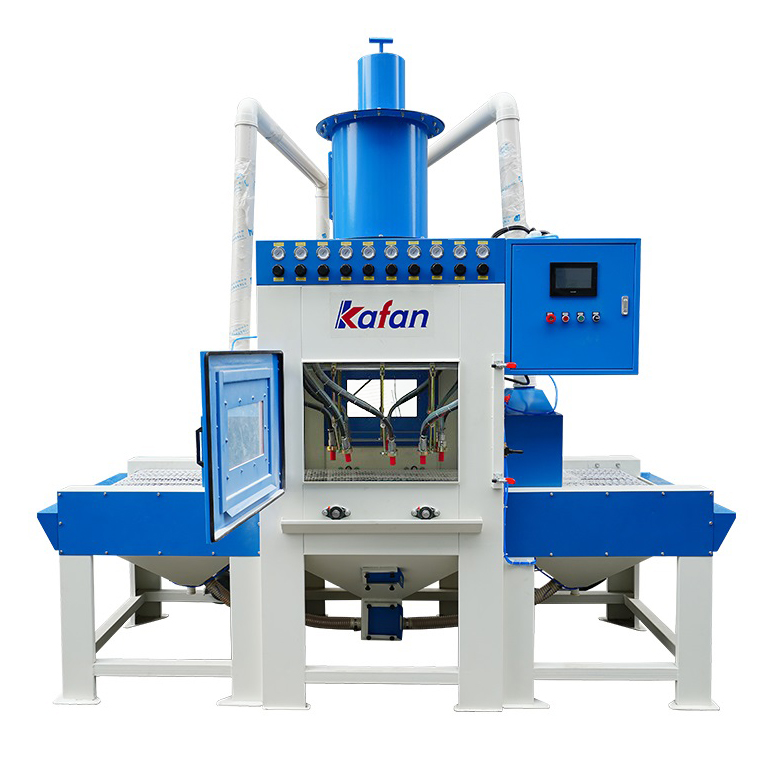

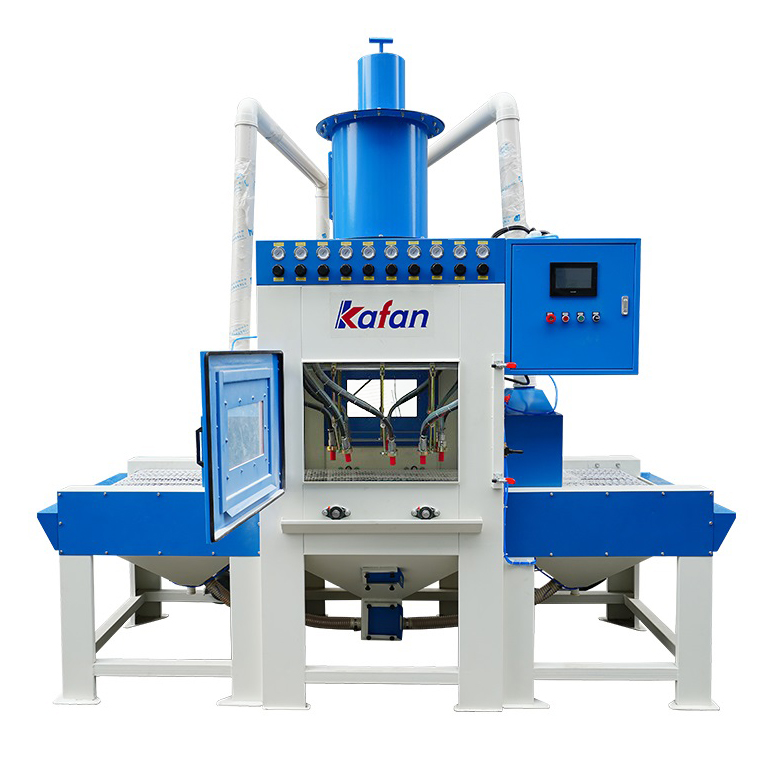

Automatic Conveyor Sandblaster for Sheet Metal

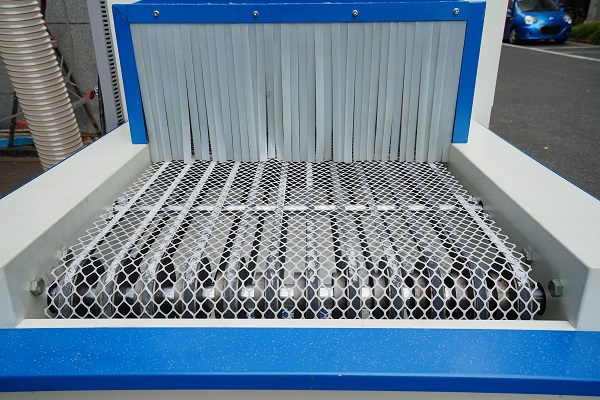

In our conveyor sandblasting machines, sheet-formed metal workparts are continuously presented to an array of pre-positioned guns, a certain quantity of blast guns are bracketed to sweep parts in linear motion synchronized with continuous movement of the belt.

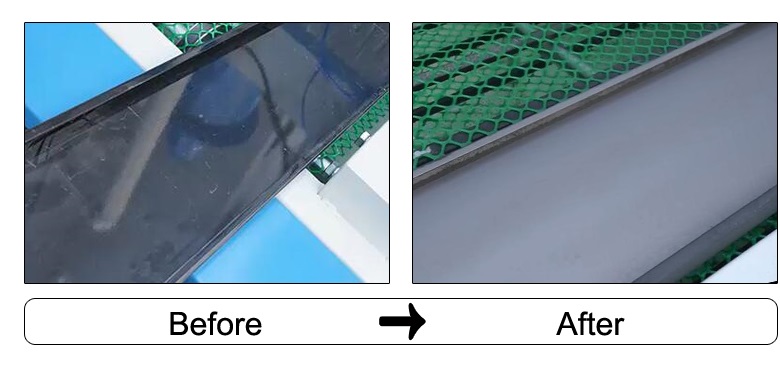

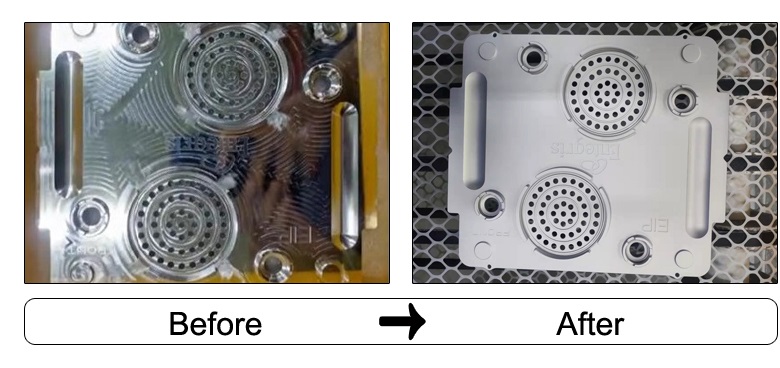

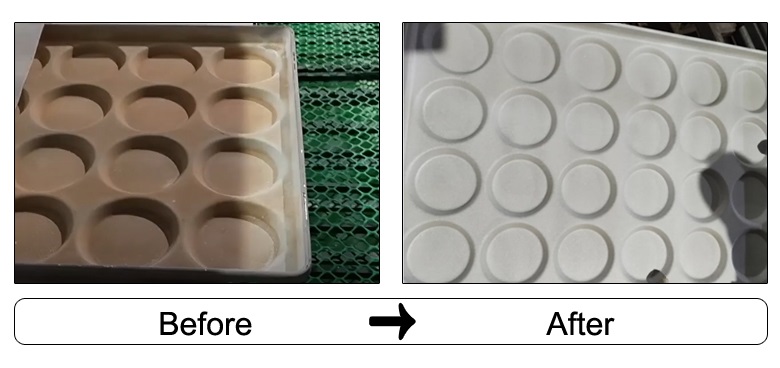

It allows a batch of workparts continuously passing through the work chamber for automatic sandblasting. Batch processing increases quality consistency, avoids the uneven blasting effect, chromatic aberration and quality problem.

Automatic Conveyor Sandblaster Applications

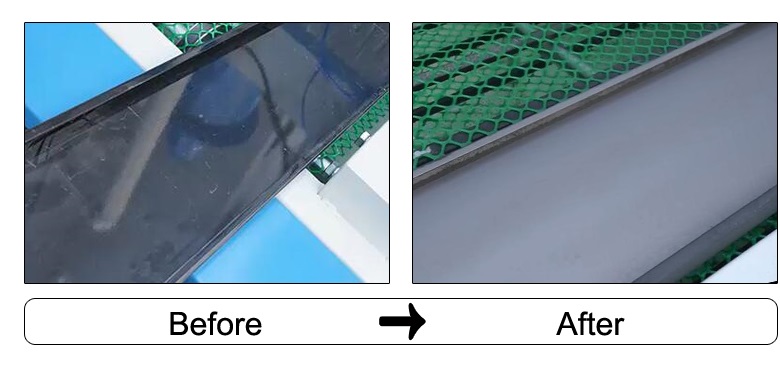

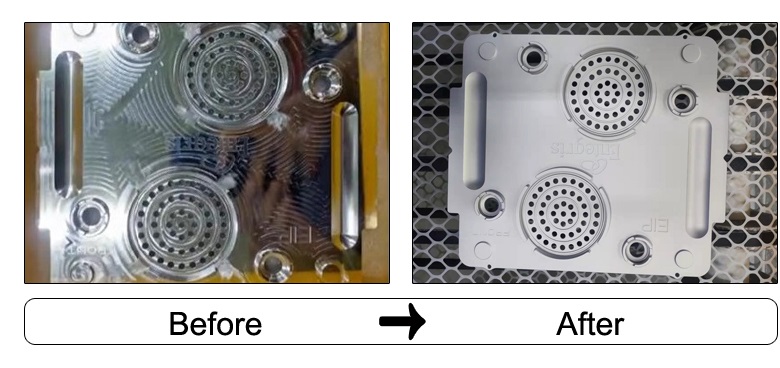

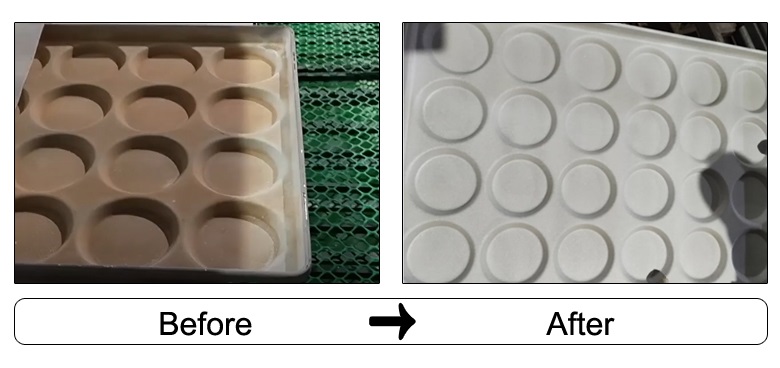

This automatic sandblaster is ideal for high-volume production of parts that cannot be subjected to part-on-part contact, recommended for processing flat shape workpieces, efficient for paint removing, rust-removing, matt-finishing with uiform quality.

How automatic conveyor sandblaster works?

The operators put or fix the workparts on the conveyor belt, when the workpiece is transported into the sandblasting chamber, the blasting guns automatically swinging and blasting, ensures the products is blasted entirely. Finally the workparts comes out from the other side of the conveyor to be discharged.

Automatic Conveyor Sandblaster Features

Automatic Blast Guns

Each blast gun is individually controlled for working by demands. Depending on the parts' shapes and dimensions, the automatic sandblast guns can be set for fixed blasting or oscillating blasting with adjustable angle and speed.

The quantity of automatic blasting guns can be customized for 4pcs, 6pcs, 8pcs, 12pcs, 16pcs, 20pcs, or more. The gun nozzle is made of durable borron carbide material.

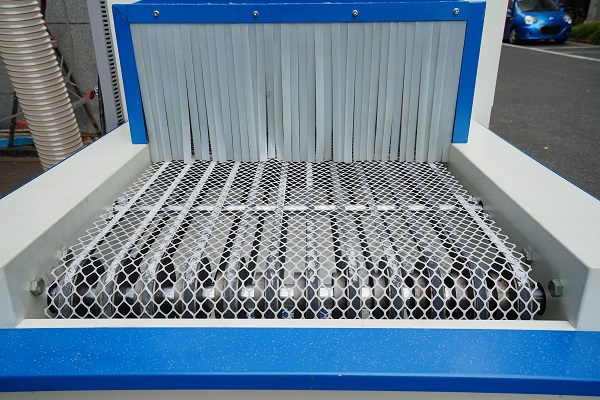

Continuous Conveyor Belt

The automatic sandblaster's conveyor motor is controlled by frequency converter, whose speed can be steplessly regulated by inverter within the range of 0 ~ 2m/min.

Several types of conveyor can be choosen to move your workparts through the blasting area, such as anti-rust stainless steel belt, durable rubber belt, or heavy-duty roller conveyor for blasting upper and lower surfaces

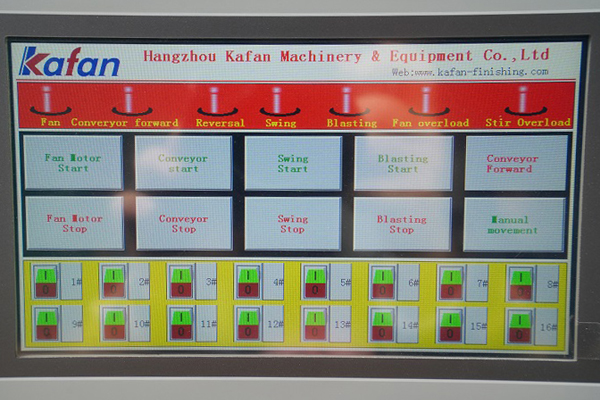

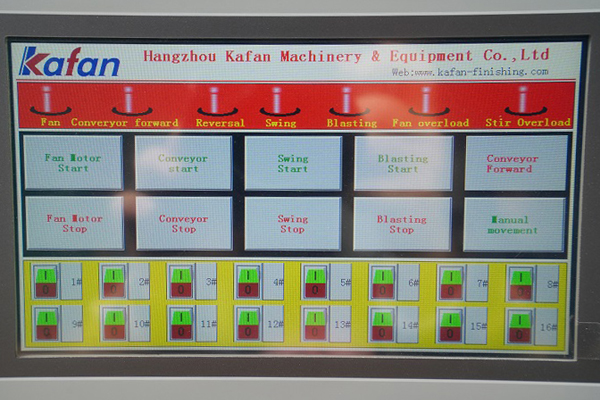

PLC Control

Applies PLC system for easy operation of electric and pneumatic controls, with a high degree of flexibility and stability. High automation guarantees the balanced uniform blasting effect, safe production

Blast working time can be easily adjusted on panel, each gun can be individually controlled, as well as adjust conveyor speed, start the dust collector.

Dust Removing & Media Recycling

Designed with cyclone separator for effectively separation of abrasives from dusts. Along with an independent cartridge filter dust removal system with excellent effect of dust extraction and ventilation.

Blast-removed dust particles are exhausted to the dust collector while blast media is collected at the bottom of the cabinet, then returned to the storage hopper for further use.

Automatic Conveyor Sandblaster Specifications

| Model | KF-2706-8A |

| Working Chamber Size | L900 x W1000 x H922mm |

| Overall Size | L2700 x W1000 x H2059mm |

| Pass Thru Size | 600 x 300mm |

| Dust Collector Size | L800 x W800 x H1300mm |

| Blasting Gun QTY | 8 pcs |

| Blasting Gun Spec. | 0.4KW |

| Dust Collector Fan Power | 5.5kw |

| Dust Collector FIlters | 6 pcs |

| Conveyor Speed | 0-5m/min adjustable |

| Conveyor Motor Power | 0.75kw |

| Compressed air | 35CFM/Per Gun, 3-8bar(kg/cm2) |

Why Choose an Automatic Conveyor Sandblaster?

1) High efficiency and high degree of automation: Enables continuous operation, significantly reducing manual intervention and loading/unloading time, with production efficiency 5-10 times higher than traditional manual sandblasting.

2) Stable and uniform processing quality: Due to fixed conveyor speed and sandblasting parameters, consistent processing results are ensured for every workpiece in the same batch, making quality controllable.

3)Improved working environment: Fully enclosed operation, with efficient dust collection and filtration, and noise isolation, is environmentally friendly and protects worker health.

4) Reduced labor intensity and costs: Operators are mainly responsible for loading, unloading, and monitoring, requiring less physical exertion and having low reliance on skilled workers.

5) Abrasive recycling: Equipped with a highly efficient abrasive separation and recycling system, abrasives can be reused, reducing consumable costs.