Direct Pressure Blast Cabinet, High Pressure Sandblasting Cabinet

Those blast cabinets are specially designed with a pressurized pot containing compressed air that pushes and accelerates the media to the nozzles through a media outlet valve, then blast them onto the target. The compressed air is the origial power source of both abrasive supply and speed accelerate.

Why Using a Direct Pressure Blast Cabinet?

As the abrasive is conveyed at a much higher velocity and blasted at stronger force. comparing with suction cabinets, pressure blaster has obvious advantages:

With less efforts and time for removing heavy burrs or stripping thick layers.

Large surface areas can be cleaned quickly.

Job is completed 3-5 times faster than siphon time, greatly increase the productivity.

Allows the use of heavy media or large mesh sizes for special needs

Direct Pressure Blast Cabinet Configurations

Blast Cabin

Cabinet design, enclosed type without dust and abrasive leakage, cause no pollution to environment and protect users' health.

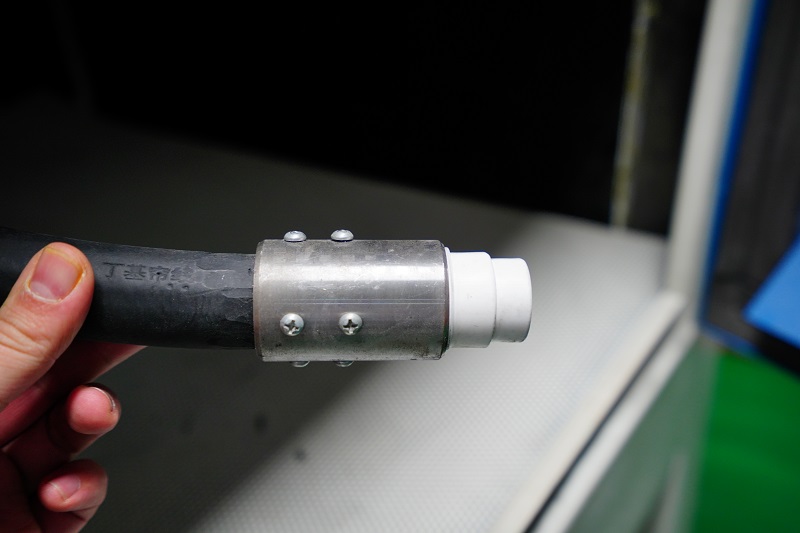

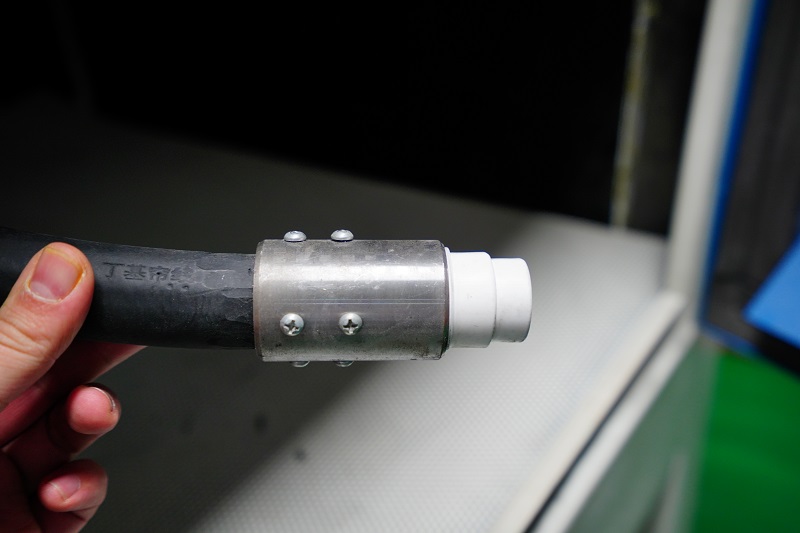

Sandblasting Gun

Each blast cabinet configures a blasting gun with alloy holder and durable boron carbide nozzle

Air Blowing Gun

Using after sandblasting process - removal of surplus dust and blasting media.

Foot Switch

Control the work of blasting gun, which reduces the user's fatigue, safe and reliable.

Pressurized Pot

The advanced pressure abrasive valve, improves processing quality, reduces the compressed air consumption.

Dust Collector

High precision filter cartridge effectively keeps dust away from the blast chamber for the operator's visibility.

Custom-made Direct Pressure Blast Cabinet

The size and configurations of pressure blast cabinet can be customized according to customer requirements, such as installing with turntable and loading cart for heavy duty products, or making with 2, 3, or 4 working cabins to operate oversized workparts.

Optional Turntable & Cart

Multiple Working Stations

Direct Pressure Blast Cabinet Specifications

Model

| KF-9080P |

| Outside Size | L1650*W1000*H21000mm |

| Work Cabin Size | L900*W800*H800mm |

| Max.Loading | 80-100kgs |

| Dust Collector Size | L430*W430*H1600mm |

| Pressure Tank | Diameter350mm, height450mm |

| Pressure Gauge | 2 pieces. |

| Number of gun | 1 set with boron carbide nozzle |

| Power supply | 110V/220V/380V/410V/450V/(50-60Hz), made as local. |

| Dust Collector motor | 0.55kw |

| Lighting | 18w fluorescent |

| Air source requirement:: | pressure 5-8bar (kg / square meter) |

Hot Sale Standard Modes of Direct Pressure Blast Cabinet

| Model | Working Cabinet Size | Loading Capacity |

| KF-9080P | L900*W800*H800mm | 80-100kgs |

| KF-1010P | L1000*W1000*H800mm | 80-100kgs |

| KF-1212P | L1200*W1200*H800mm | 100-120kgs |