Continuous Rotary Sandblasting Machine, Automatic Batch Blasting System

The rotary automatic sandblasting machine is built with multi-independently rotating work stations on an indexing table, both rotating in 360 degree. Continuous rotary type automatic blasting system is ideal for processing bar shaped workparts to refurbish surfaces, significantly increasing work efficiency and production ouput.

How Continuous Rotary Automatic Sandblasting Machine Works?

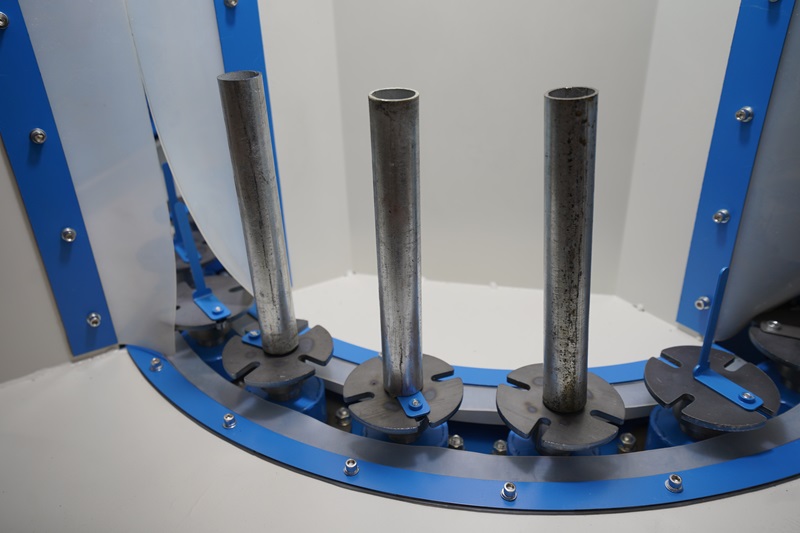

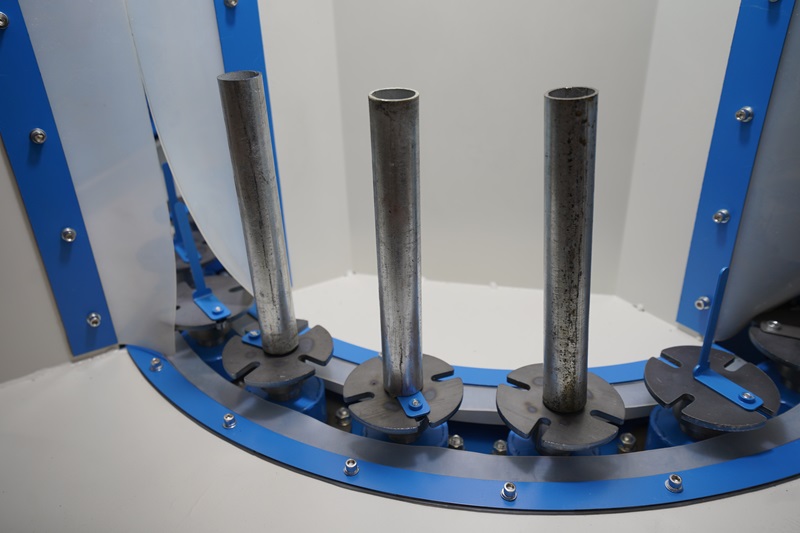

There are several small turntable evenly spaced on the indexing table, each small turntable is a working platform which will be fixed with one piece of workparts. Multiple platform ensures high productivity and efficiency.

After operators fix the parts in the small turntables, the large table continuously drives them and presents them in front of blast gun for automatic processing, and automatic guns make fixed blasting or oscillating blasting to make a uniform and complete finish. After blasting, the blasted workparts will be sent to the blowing room for dust removing, then sent to the unloading station which is also the loading station.

Continuous Rotary Automatic Sandblasting Machine Features:

Automatic Blast Guns

Workparts are rotated to the blasting area where they are processed by automatic guns.

Each blast gun is individually controlled for working by demands. Depending on the parts shapes and dimensions, the blast guns can be set for fixed blasting or oscillating blasting with adjustable angles.

Multiple Working Platforms - Small Turntables

Small working turntables are evenly spaced presenting workparts in front of blast gun for automatic processing. They are driven through independent motors, stepless speed regulation by converter. Specially fixtures on the turntable can be customized for quick and solid clipping to improve efficiency.

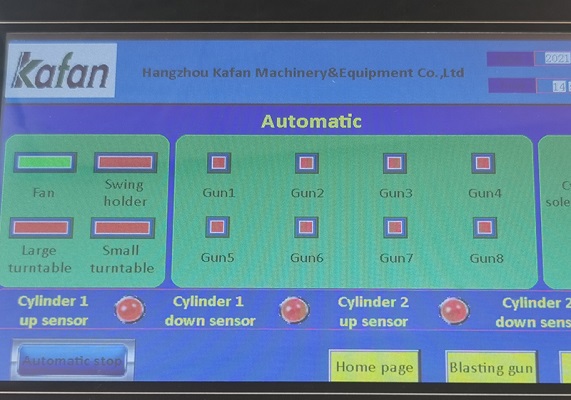

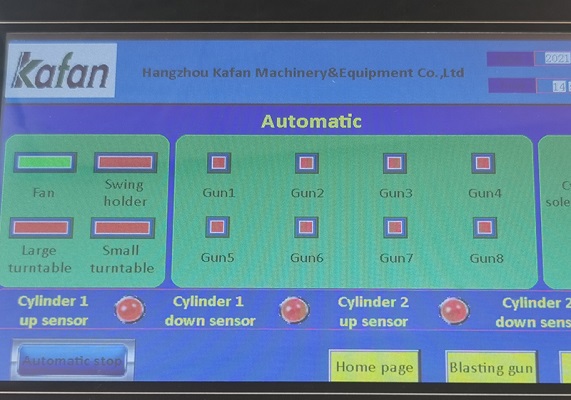

PLC Control with Touching Screen

High automation and accuracy task controlled by PLC system, guarantee the balanced uniform blasting effect, as well as safe production.

The touching screen offers user-friendly interface to manage the blast working, such as adjust the rotating speed, set blast time, control each blast gun and set the dust collector.

Dust Removing & Media Recycling

Designed with cyclone separator for effectively separation of abrasives from dusts. Along with an independent cartridge filter dust removal system with excellent effect of dust extraction and ventilation. Blast-removed dust particles are exhausted to the dust collector while blast media is collected at the bottom of the cabinet, then returned to the storage hopper for further use.

Continuous Rotary Automatic Sandblasting Machine Technical Parameters:

| Model: | KF-1618-12A |

| Overall Dimension | 1600x1800x2300mm |

| Dust Collector Size | 1200x1200x1700mm |

| Index Turntable Size | Dia 1000mm |

| Drive Motor Power | 1.1kw |

| Qty of Small Turntables | 8pcs |

| Drive Motor Power | 0.75kw |

| Max. Size of Parts Allowed | Dia 350mm x Height 400mm |

| Qty of Blast Guns | 12 pcs |

| Blast Gun Nozzle | Durable Boron Carbide |

| Power Supply | 380V/220V As required |

| Separator Power | 5.5kw |

| Compressed Air Source | 8-12 bar |