KF-1719-12A

Kafan

| Availability: | |

|---|---|

This automatic sandblasting machine is designed with multiple small turntables evenly distributed on an indexing rotary table, all in a satellite arrangement. Inside the closed cabinet there are group of automatic guns sweeping workparts for cleaning and finishing

As each workpart is independently clamped on a turntable and got full coverage of abrasive flow, it is ideal for batch processing of small cylindrical or complex shaped products

This automatic blasting system only requires one operator stand at the front opening station to load and unload the products

This automatic blasting machine activates through a large turntable taking a quantity of small turntables, both rotating in 360 degree. After operators clip the parts in the small turntables, the large turntable drives them to the automatic blasting stations, and automatic guns swing and blasting to make a high quality finish.

It allows blasting parts getting an exact quality or design standard, production supervisors can be assured of every part on every shift being blasted in exactly the same way with an Rotary Tabel Automatic Sand Blasting Machine

(the video shows how the automatic blaster works and application for cooking pot)

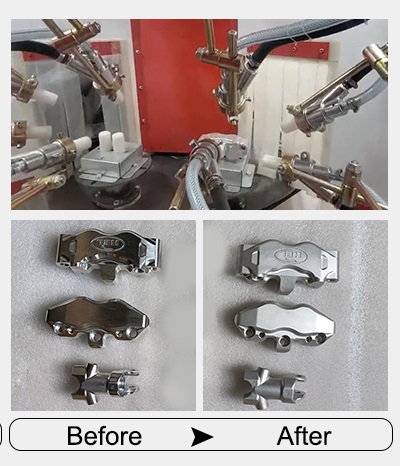

Automatic Blast Guns

Small turntables fixed with workparts are rotated to the blasting area where they are processed by a group of automatic guns.

Depending on the parts shapes and dimensions, the blast guns can be set for fixed blasting or oscillating blasting with adjustable angles and speed.

Blasting time, blasting distance between parts and gun also can be adjusted to optimize processing.

Multiple Working Platforms - Small Turntables

Small working turntables are evenly spaced in the big index table, They will be presented in front of automatic blast guns. They are driven through independent motors, stepless speed regulation by converter.

Specially fixtures on the turntable can be customized for quick and solid clipping to improve efficiency.

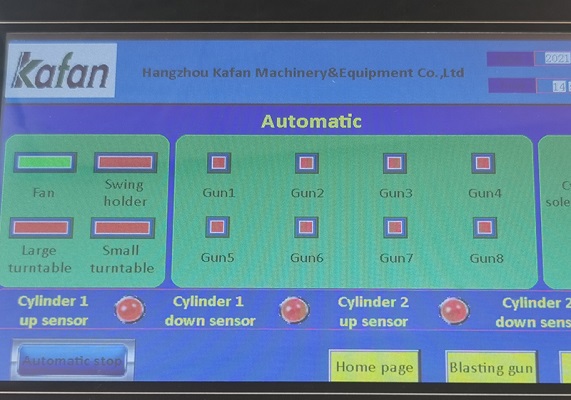

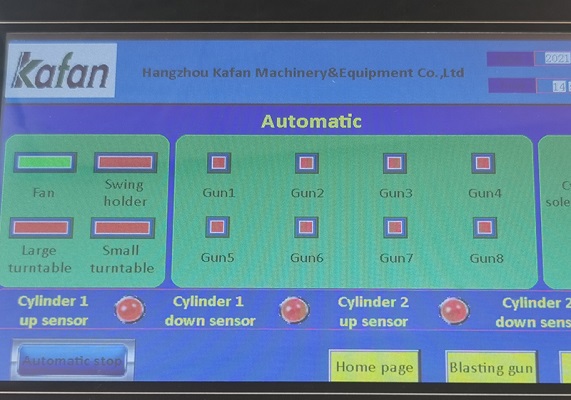

PLC Control with Touching Screen

High automation and accuracy task controlled by PLC system, guarantee the balanced uniform blasting effect, as well as safe production.

The touching screen offers user-friendly interface to manage the blast working, such as adjust the rotating speed, set blast time, control each blast gun and set the dust collector.

Dust Removing & Media Recycling

Designed with cyclone separator for effectively separation of abrasives from dusts. Along with an independent cartridge filter dust removal system with excellent effect of dust extraction and ventilation.

Blast-removed dust particles are exhausted to the dust collector while blast media is collected at the funnel of the cabinet, then returned to the storage hopper for further use.

| Model: | KF-1719-12A |

| Main Dimension | 1700x1900x2350mm |

| Dust Collector Size | 1400x1400x1700mm |

| Large Turntable Size | Dia 1400mm x Thick 15mm |

| Qty of Small Turntables | 12pcs |

| Small Turntable Size | 150/180mm |

| Loading Capacity of Small Turntable | 20kgs |

| Max. Size of Parts Allowed | Dia 350mm x Height 450mm |

| Qty of Blast Guns | 8pcs |

| Blast Gun Nozzle | Durable Boron Carbide |

| Power Supply | 380V/220V As required |

| Total Power | 7kw |

| Machine Weight | 4150kgs |

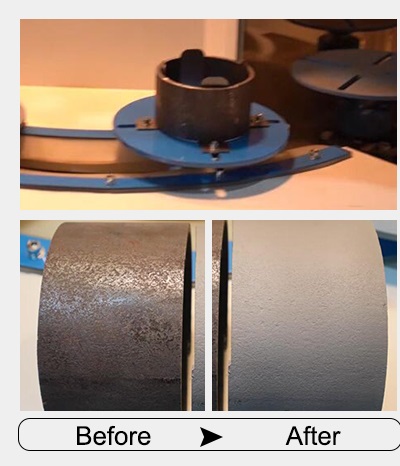

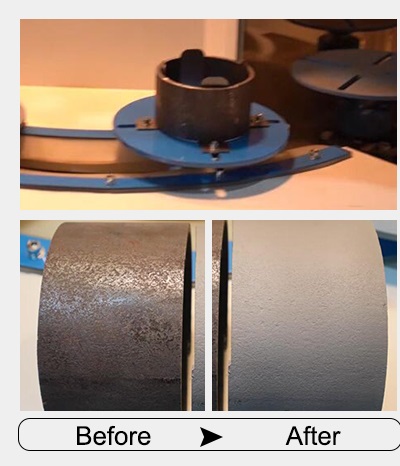

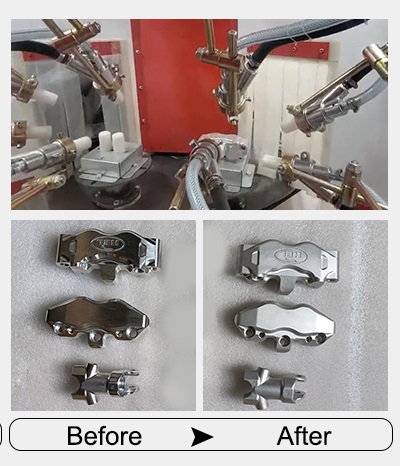

The automatic sandblasting machine is ideal for batch processing of irregular shaped parts, especially for cylindrical objects, such as non-stick pan, rice cooker, glass & metal lampshade,baking pan, stainless steel wash basin, wine bottle, glass cup, motorcycle or auto parts, etc. The sandblasting machine effectively remove rust, or roughs surfaces in great uniformity.

This automatic sandblasting machine is designed with multiple small turntables evenly distributed on an indexing rotary table, all in a satellite arrangement. Inside the closed cabinet there are group of automatic guns sweeping workparts for cleaning and finishing

As each workpart is independently clamped on a turntable and got full coverage of abrasive flow, it is ideal for batch processing of small cylindrical or complex shaped products

This automatic blasting system only requires one operator stand at the front opening station to load and unload the products

This automatic blasting machine activates through a large turntable taking a quantity of small turntables, both rotating in 360 degree. After operators clip the parts in the small turntables, the large turntable drives them to the automatic blasting stations, and automatic guns swing and blasting to make a high quality finish.

It allows blasting parts getting an exact quality or design standard, production supervisors can be assured of every part on every shift being blasted in exactly the same way with an Rotary Tabel Automatic Sand Blasting Machine

(the video shows how the automatic blaster works and application for cooking pot)

Automatic Blast Guns

Small turntables fixed with workparts are rotated to the blasting area where they are processed by a group of automatic guns.

Depending on the parts shapes and dimensions, the blast guns can be set for fixed blasting or oscillating blasting with adjustable angles and speed.

Blasting time, blasting distance between parts and gun also can be adjusted to optimize processing.

Multiple Working Platforms - Small Turntables

Small working turntables are evenly spaced in the big index table, They will be presented in front of automatic blast guns. They are driven through independent motors, stepless speed regulation by converter.

Specially fixtures on the turntable can be customized for quick and solid clipping to improve efficiency.

PLC Control with Touching Screen

High automation and accuracy task controlled by PLC system, guarantee the balanced uniform blasting effect, as well as safe production.

The touching screen offers user-friendly interface to manage the blast working, such as adjust the rotating speed, set blast time, control each blast gun and set the dust collector.

Dust Removing & Media Recycling

Designed with cyclone separator for effectively separation of abrasives from dusts. Along with an independent cartridge filter dust removal system with excellent effect of dust extraction and ventilation.

Blast-removed dust particles are exhausted to the dust collector while blast media is collected at the funnel of the cabinet, then returned to the storage hopper for further use.

| Model: | KF-1719-12A |

| Main Dimension | 1700x1900x2350mm |

| Dust Collector Size | 1400x1400x1700mm |

| Large Turntable Size | Dia 1400mm x Thick 15mm |

| Qty of Small Turntables | 12pcs |

| Small Turntable Size | 150/180mm |

| Loading Capacity of Small Turntable | 20kgs |

| Max. Size of Parts Allowed | Dia 350mm x Height 450mm |

| Qty of Blast Guns | 8pcs |

| Blast Gun Nozzle | Durable Boron Carbide |

| Power Supply | 380V/220V As required |

| Total Power | 7kw |

| Machine Weight | 4150kgs |

The automatic sandblasting machine is ideal for batch processing of irregular shaped parts, especially for cylindrical objects, such as non-stick pan, rice cooker, glass & metal lampshade,baking pan, stainless steel wash basin, wine bottle, glass cup, motorcycle or auto parts, etc. The sandblasting machine effectively remove rust, or roughs surfaces in great uniformity.

1. How much time does it take to sandblasting for one piece cooking pan approximetly?

About the cycle time, it takes about 20-30 seconds to blast one pan according to the feedback from our clients who bought the automatic blast machine working with pans.

2. After we buy this automatic sandblaster, just giving power and loading the sand will be enough for using this machine?

Yeah, the offer includes all parts. Ready to use. After connecting with air source and power source. It can begin to work after loading the sand.

3. In this picture, the machine has a square cabinet which stands behind or beside it. what is it?

For the one standing behind or beside the machine, it is the catridge filter dust collector. The filter unit keeps the environment clean and dustless.

4. Which type of sand could be used in this machine?

The machine can work with various sands, size from mesh 16 to mesh 320, like glass beads, aluminum oxide, garnet, steel grit, corundum, etc.

5. Is this rotary indexing machine blasting just cover the cap or it sanding outer and inner side at the same time?

The machine can blast both outer and inner side of the pan at the same time, actually cover all surfaces of objects.. The Oscillating nozzles can be adjusted on a vertical or horizontal axis.

6. As we know it consumes sand. How much sand consuming in this process? How often should we change the whole sand?

The sand consumption is about 200kgs for 8 blasting guns each week if continuous work for 6-8 hours each day. The quantity changes as per the working time and different sand. There is no need to change the sand, just add some more when find out it is less.

7.Could we send you samples to sandblast in this automatic machine? We want to see the results.

It is good idea to send us a sample for testing in our automatic sandblasting machine. Please also send good sample for reference so that we can know what surface condition you required. If any possibility, welcome to visit our factory.

1. How much time does it take to sandblasting for one piece cooking pan approximetly?

About the cycle time, it takes about 20-30 seconds to blast one pan according to the feedback from our clients who bought the automatic blast machine working with pans.

2. After we buy this automatic sandblaster, just giving power and loading the sand will be enough for using this machine?

Yeah, the offer includes all parts. Ready to use. After connecting with air source and power source. It can begin to work after loading the sand.

3. In this picture, the machine has a square cabinet which stands behind or beside it. what is it?

For the one standing behind or beside the machine, it is the catridge filter dust collector. The filter unit keeps the environment clean and dustless.

4. Which type of sand could be used in this machine?

The machine can work with various sands, size from mesh 16 to mesh 320, like glass beads, aluminum oxide, garnet, steel grit, corundum, etc.

5. Is this rotary indexing machine blasting just cover the cap or it sanding outer and inner side at the same time?

The machine can blast both outer and inner side of the pan at the same time, actually cover all surfaces of objects.. The Oscillating nozzles can be adjusted on a vertical or horizontal axis.

6. As we know it consumes sand. How much sand consuming in this process? How often should we change the whole sand?

The sand consumption is about 200kgs for 8 blasting guns each week if continuous work for 6-8 hours each day. The quantity changes as per the working time and different sand. There is no need to change the sand, just add some more when find out it is less.

7.Could we send you samples to sandblast in this automatic machine? We want to see the results.

It is good idea to send us a sample for testing in our automatic sandblasting machine. Please also send good sample for reference so that we can know what surface condition you required. If any possibility, welcome to visit our factory.