Double Station Pressure Sand Blast Cabinet

The large sandblast cabinet is customer-made with 4 working stations, which is required to operate extremely long workparts, such as aluminum profiles. Unlike normal blaster sucking medias, this blast cabinet works through a pressurized pot directly pushing and accelarating the medias for blasting jobs.

What is the benefit of pressure sandblasting cabinet?

As the medias are delivered at a much higher velocity that causing poweful cutting force, work can be done 3-5 times faster than a suction blast cabinet. Moreover the pressure blast cabinet ideally supports for tough cleaning jobs, such as removing heavy burrs, stripping thick coatings or oxide layers, and allows using heavy abrasives(like steel ball) to clean hard surfaces such as casting parts, stamping parts, etc.

Large Pressure Sandblast Cabinet Features

The 4 working-station blast cabinets can be operated from both sides, means there are 8 inspection window, 8 blasting guns and 8 pair of blasting gloves. The inner chamber is built with rollers for easy moving of heavy workparts.

Pressure Sandblast Cabinet Configurations

Enclosed cabin design without dust leakage during blasting, cause no pollution to environment and is safe to operators.

Built with filter cartridge collector to capture even ultrafine dust, filter is automatically cleaned by pulse valve. It ensures vented air is clean.

Newly-developed pressure abrasive valve improves processing quality, reduces compressed air consumption.

Pressure type blast guns with boron carbide nozzles are extremely durable that guarantees long service life.

Using abrasives are stored in the bottom funnels for easy recycling, thus reduce your handling cost.

Pressure are simple to adjust by regulators and read on guage, blasting gun can be controlled by foot padel that is safe and effortless for operators.

Large Pressure Blast Cabinet Specifications

Model

| KF-4411D-4A |

| Working Chamber Size | L4400*W1100*H850mm |

| Overall Size | L4450*W1650*H2150mm |

| Dust Remove | Filter Cartridge Dust Collector |

| Body Material | 2.0mm Cold-rolled Steel Plate Welded |

| Pressure Vessel | Diameter350mm x Height450mm, 4pcs |

| Anti-explosion Inspection Window | 8 pcs |

| Blasting Gloves | 8 pcs |

| Blast Gun | High Pressure Blast Guns, 4pcs |

| Blast Gun Nozzle | Boron Carbide Nozzles, 10mm, 4pcs, |

| Dust Collector motor | 1.5kw |

| Lighting | LED, 18w |

| Air Source | Pressure 5-8bar (kg / square meter) |

| Voltage | made as local. |

We can design sandblast cabinet in different sizes and configurations as your precise requirements.

Why choose Kafan sandblasting cabinet?

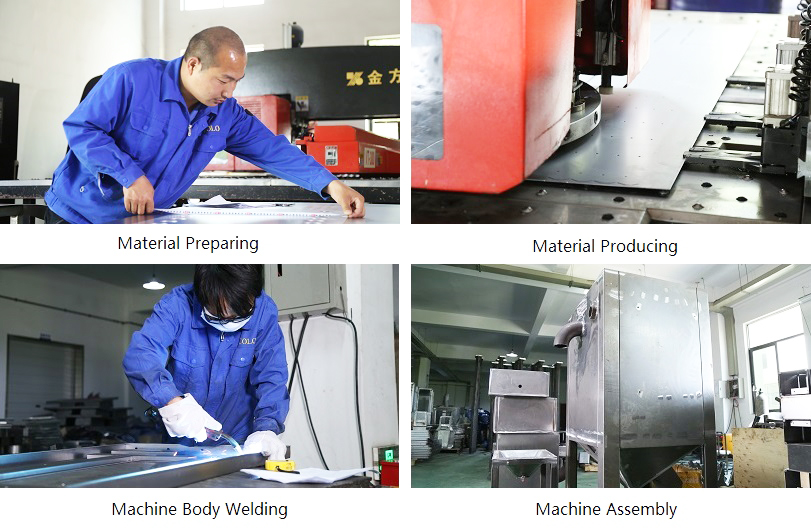

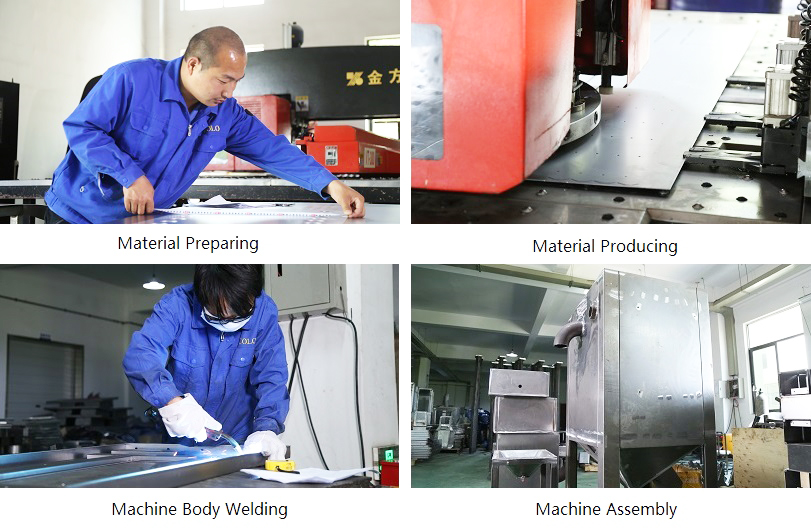

Devoted to world market for over 10 years, Kafan offer you factory-direct manufactured sand blasting machine in high quality and competitive price. With professional sales, techinical, production team, we provide blasting equipments in a variety of specifications and styles based on customers' requirements. Such as suction blast machine, pressure blast machine, portable blaster, wet blasting machine, automatic conveyor blast machine.

To pursue best performance, we use the latest technology for our products, each cabinets are fully welded with 2mm steel plate with powder-coated surfaces, equipped with premium quality components that both have been designed and tested by us for optimal performance., by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.