Automatic Inline Sandblasting Machine with Continuous Conveyor

Automatic inline sandblasting machine with U-shape conveyor belt has continuous flow production with seamless integration with the production line.

This system is suitable for high-volume production of parts varying in shape, size, and complexity, especallly for relatively sheet-form parts – such as metal panels.

Automatic conveying and blasting ensures high output, increases quality consistency, avoids the uneven blasting effect, chromatic aberration and quality problem.

How automatic inline sandblasting machine works?

In the automated blasting system, components are continuously presented to an array of pre-positioned guns as the parts are conveyed in and out of the blast chamber on an adjustable-speed belt. Up to 8 (or more) suction-blast guns are bracketed to sweep parts in linear motion synchronized with continuous movement of the belt.

Continuous Conveyor Automatic Sandblasting Machine Features

Automatic Blast Guns

Workparts are conveyed to the blasting area where they are processed by automatic guns. Each blast gun is individually controlled for working by demands.

Depending on the parts' shapes and dimensions, the blast guns can be set for fixed blasting or oscillating blasting with adjustable angles.

The quantity of blasting guns can be configured 8pcs, 12 pcs, 16 pcs or more, Nozzles in wear-resistant boron carbide material.

Continuous Conveyor Belt

The conveyor motor is controlled by frequency converter, whose speed can be steplessly regulated by inverter within the range of 0 ~ 2m/min. Several types of conveyor belt are available to move your parts through the blasting area, such as stainless steel belt, rubber belt, or roller conveyor for blasting top and bottom surfaces

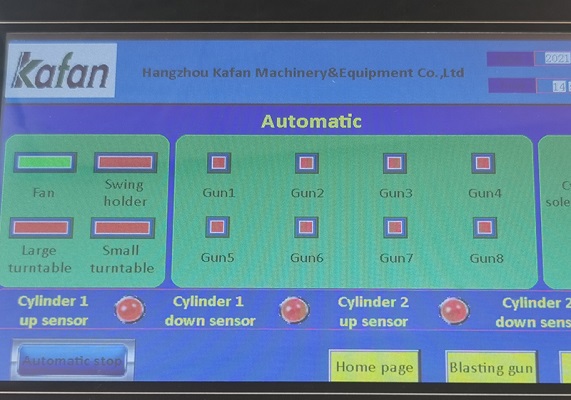

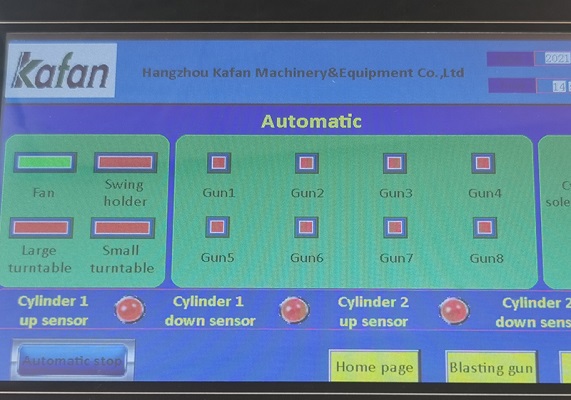

PLC Control with Touching Screen

The sandblaster applies advanced PLC electric control system, with a high degree of flexibility and stability. The touching screen offers user-friendly interface to manage the blast working, adjust conveyor speed or start the dust collector. High automation guarantees the balanced uniform blasting effect, as well as safe production

Dust Removing & Media Recycling

Designed with cyclone separator for effectively separation of abrasives from dusts. Along with an independent cartridge filter dust removal system with excellent effect of dust extraction and ventilation, Blast-removed dust particles are exhausted to the dust collector while blast media is collected at the bottom of the cabinet, then returned to the storage hopper for further use.

Continuous Conveyor Automatic Sandblasting Machine Specifications

| Type: | Pass Though Conveyor Type |

| Model: | KF-2706-8A |

| Overall dimensions: | Length2700 * Width1000 * Height2059 mm |

| Working Space dimension: | Length900 * Width1000 * Height922 mm |

| Through Size | Length600 * Width300 mm |

| Dust collector size: | Length1200 * Width700 * Height1900mm |

| Dust fan motor power: | 5.5kw |

| Conveyor motor | 0.75kw, 0-2 m/min speed adjustable |

| Blast gun motor | 0.4kw, frequency adjustable |

| Machine material: | 2.5mm-6mm cold-rolled steel plate welded |

| Perspective window: | 2 frames |

| Abrasive funnel | 3pcs |

| Pressure | 7 bar (kg / cm2) |

| Air compressor | 8 cubic meter/min |

| Total power: | 7KW |

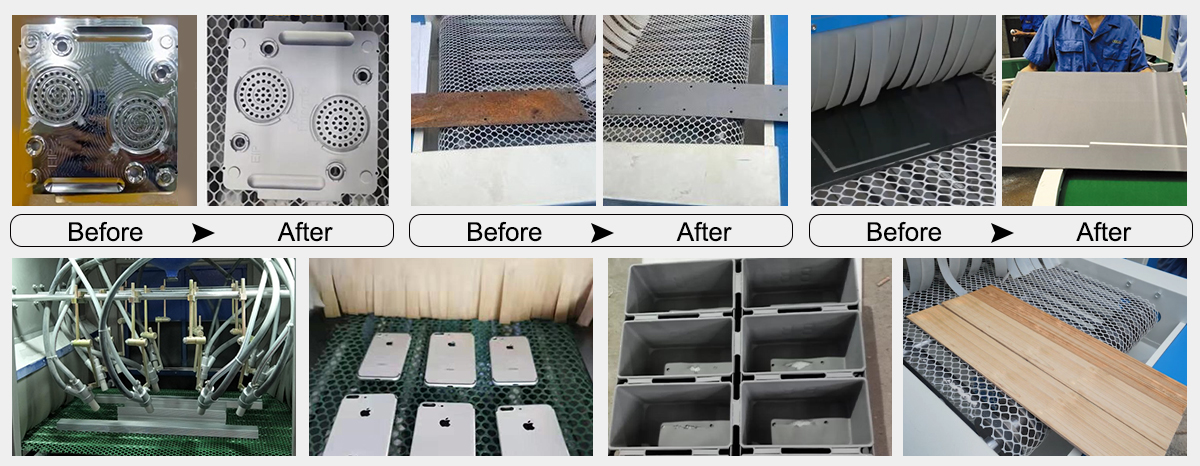

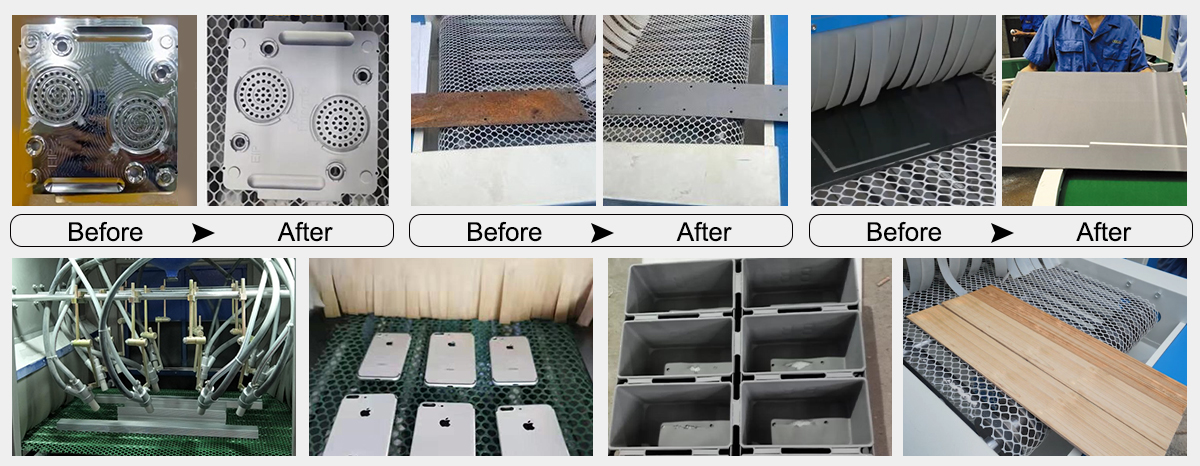

Continuous Conveyor Automatic Sandblasting Machine Applications

Application: ideal for processing flat shaped workpieces such as: aluminum plate, glass plates, ceramic tile, steel plate, stainless steel plate, mobile shell, notebook computer shell, etc Widely used for cleaning contaminants, removing rust and old coatings, etching and decorating, roughing surface, etc