Roller Conveyor Automatic Sand Blasting Machine for Double Sided Surfaces

The automatic sand blasting machine with roller conveyor and double working stations allows workparts' double faces or all dimentional surfaces to be cleaned with upper blast gun group and lower blast gun group, thus it reduces manual labor to turn over the workparts and greatly increases processing efficiency.

It is a fully automated sandblaster only requires operator loading and discharging the workparts, also can be conntected with existing production line.

Roller Conveyor Sand Blasting Machine Excellent Features

Specially built with upper and lower working station, each station has a group of 6pcs automatic guns, blasting surfaces from upper and bottom directions, designed with observation window, users can observe the entire process and ready to deal with unexpected situations.

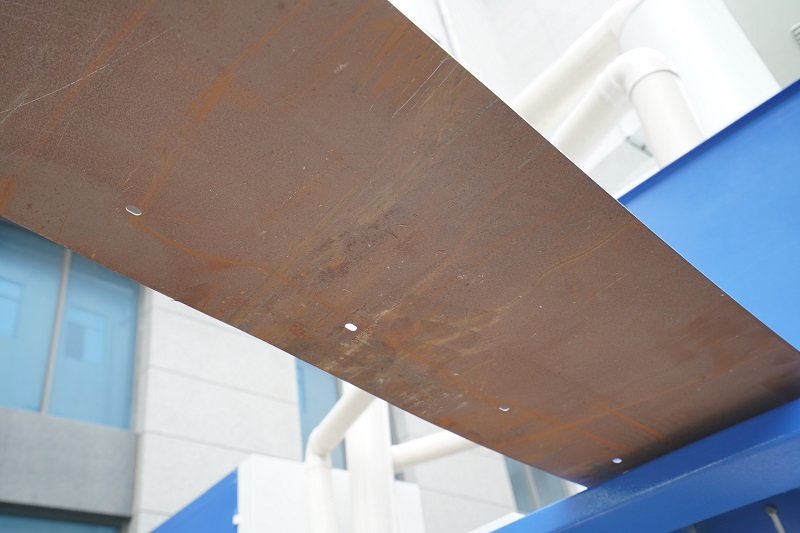

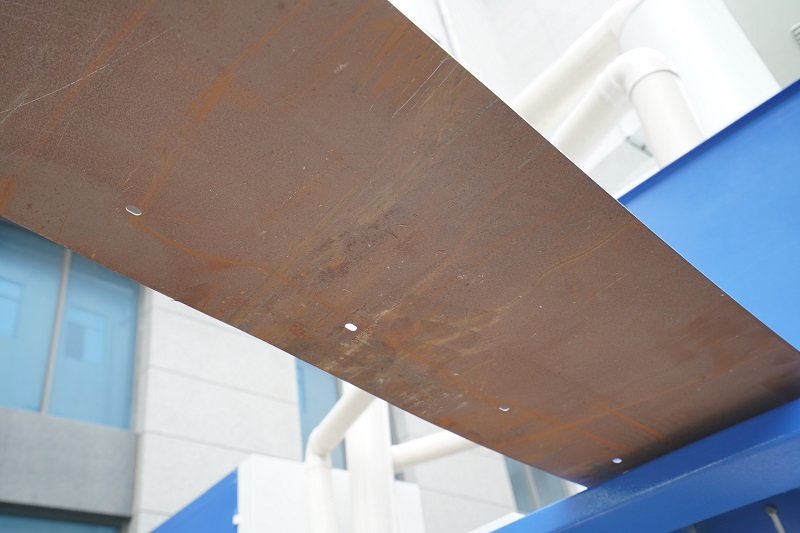

upper blast guns

lower blast guns

lower blast guns

Roller Conveyor Automatic Sand Blasting Machine Applications

The specially-designed roller conveyor sand blasting machine is ideal for surface treatment of steel plates, aluminium plates, square tube, round tube, aluminium profiles, etc, which require upper and uder suface to be cleaned, likes removing rust/old paints, repairing scratches or strenthening surface adhesion.

Roller Conveyor Sand Blasting Machine Configurations

Roller Conveyer

heavy-duty roller conveyor is driven by the motor controlled via frequency converter, and the conveyor speed can be steplessly regulated by the inverter within the range of 1 ~ 5m / min. The actual speed is set depending on process requirements of workpieces.

Automatic Blast Guns

The blast gun adopts linkage swinging mechanism, whose swinging angle and distance can be adjusted according to the requirements. Each blast gun can be individually comtrol via PLC. Aluminum alloy material with durable boron carbide nozzles ensures longer service life.

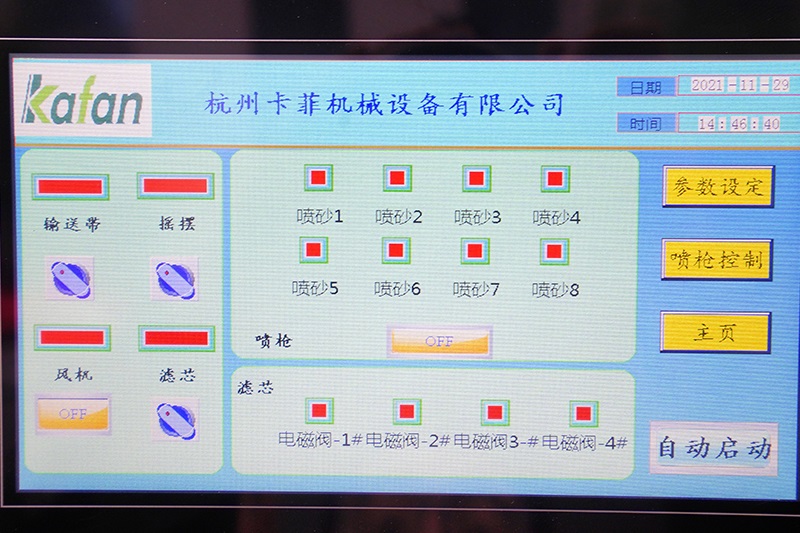

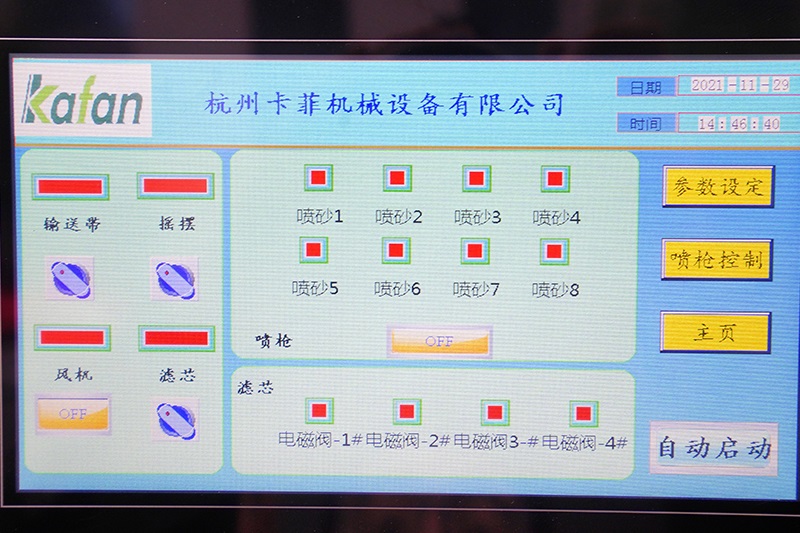

PLC Control System

The automatic sandblaster applies advanced PLC control system achieves high automation and stability, guarantees the balanced uniform blasting effect, as well as safe production. The user-friendly touching screen unterface facilitate the operation.

Filter Dust Collector Unit

Dust Collector: Independent dust collector consists of 6 pcs cartridge filter stage and 7.5kw fan motor for effectively dust removing, powerfully remove dust, keeps the working chamber a clear view and increases abrasive recyling rate, as well as ensures only dust-free air vented that causes no pollution for environment.

Roller Conveyor Sand Blasting Machine Specifications

| Overall size | Length3100mm * Width3692mm * Height3306mm |

| Dust collector size | 1000*1000*1750mm |

| Suitable workpiece | width≤600mm, height≤400mm, no limit to length |

| Conveyor speed | 1~5m/min, stepless speed regulation |

Conveyor motor

| 0.75kw, 2 sets |

| Blasting gun | 12pcs, each side with 6pcs |

| Gun swinging motor | 0.4kw, 2sets

|

| Nozzle material | Boron carbide nozzles. |

| Cartridge filter | 6pcs, 100% polyester |

| Dust collector motor | 5.5kw |

| Power supply | 380V, 50Hz, 3 phase(voltage can be made as local) |

| Total Power | 8kw |

Automatic Conveyor Sand Blasting Machine Benefits

Only requires to manually operate the control system, load and unload the workpiece.

Continuous conveying blasting features high working efficiency, increase output.

Allowing batch processing improve quality consistency, avoids the uneven quality problem.

Full-customization available, according to workparts' sizes, shapes and finishing requirements.

suitable for products whose width and height within a certain range, while mo limit with the length.