Custom-made Pressure Feed Blast Cabinet

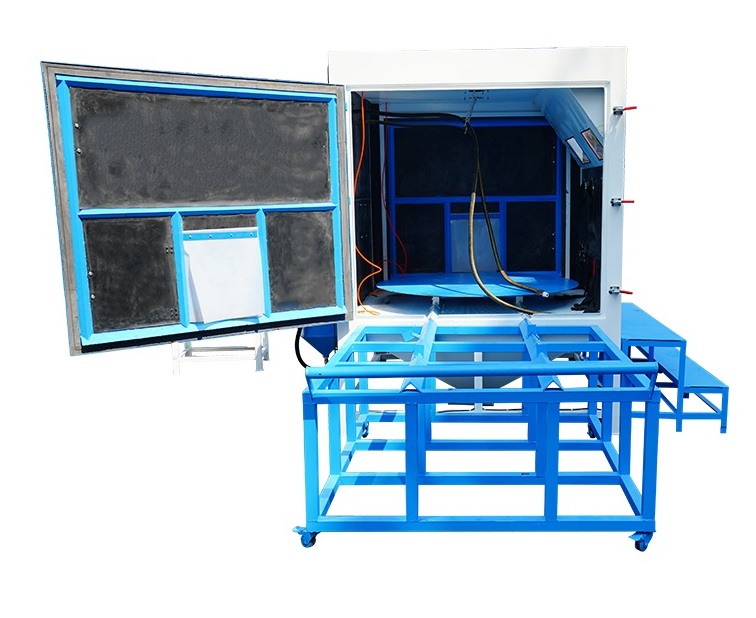

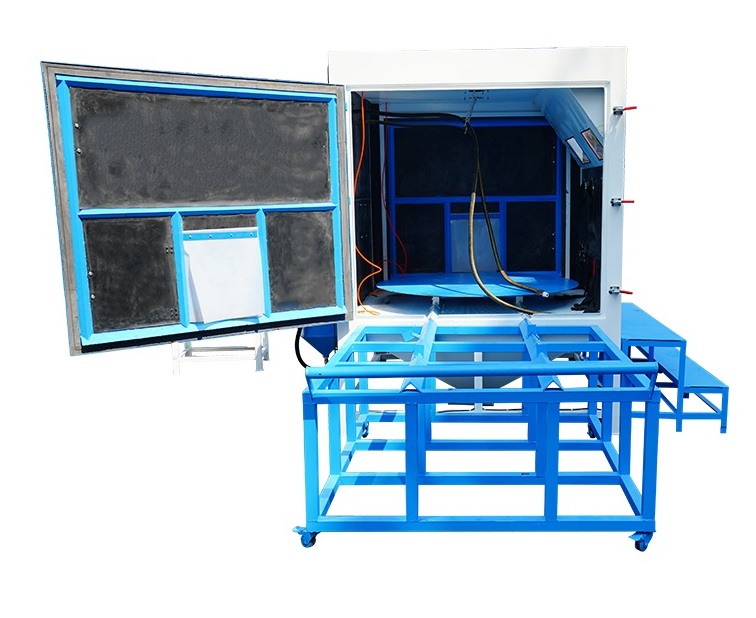

This pressure feed blast cabinet is specially designed with dual working stations in 2 layers , which is required to efficiently operate larger workparts. Works by directly pushing and accelarating the medias to target surfaces through hose and nozzle, this blaster delivers media at a much higher velocity that causes poweful cutting force.

Pressure blast cabinet is ideal for tough cleaning jobs, such as removing heavy rust, thick coating layers, also makes it easy to handle hard stuffs, work can be done 3-5 times faster than a suction blast cabinet

Pressure Blast Cabinet Features

Enclosed cabin design without dust leakage during blasting, cause no pollution to environment and is safe to operators.

Filter cartridge dust collection system is designed to keep dust away from the operator's window for increased visibility and accuracy when cleaning.

Used abrasives are collected in the funnel that can be recycled for many times, reducing consumption and save cost.

Newly-developed pressure abrasive valve improves processing quality, reduces compressed air consumption.

Pressure type blast gun with boron carbide nozzle are extremely durable that guarantees long service life.

Can be designed with an optional turntable and cart to easily roll the workparts in and out through the track, with minimum force to blast finishing the workparts.

Three Station Pressure Blast Cabinet Specifications

Model

| KF-1818P-2 |

| Working Chamber Size | L1800 * W1800 * H1600mm |

| Body Material | 2.0mm Cold-rolled Steel Plate Welded |

| Pressure Vessel | Diameter350mm x Height450mm, 2pcs |

| Pressure Regulator | 2 pcs |

| Blast Gun | High Pressure Blast Guns, 2pcs |

| Blast Gun Nozzle | Boron Carbide Nozzles, 8mm, 2pcs, |

| Dust Collector motor | 1.5kw |

| Air Source | Pressure 5-8bar (kg / square meter) |

| Voltage | made as local. |

Why choose Kafan sandblasting cabinet?

Devoted to world market for over 10 years, Kafan offer you factory-direct manufactured sand blasting machine in high quality and competitive price. With professional sales, techinical, production team, we provide blasting equipments in a variety of specifications and styles based on customers' requirements. Such as suction blast machine, pressure blast machine,portable blaster, wet blasting machine, automatic conveyor blast machine.

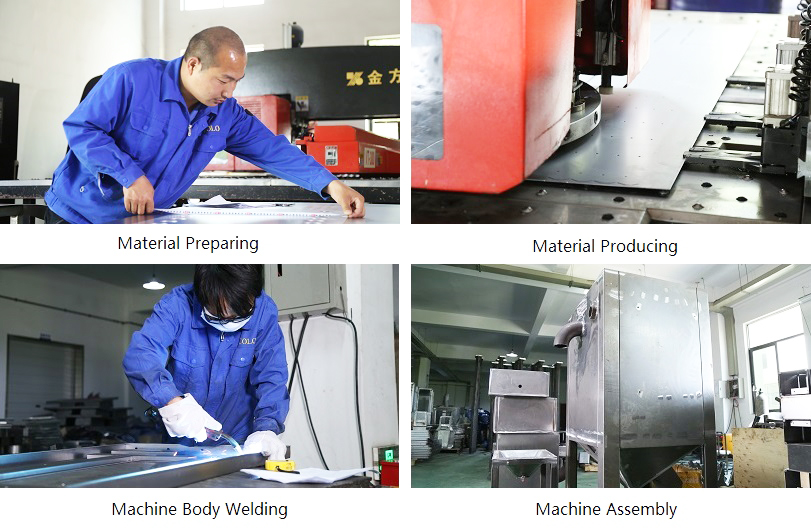

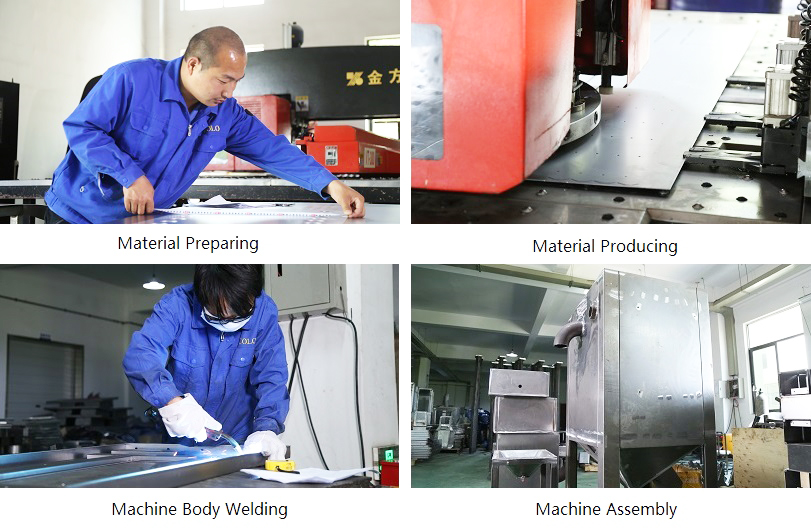

To pursue best performance, we use the latest technology for our blast components, our cabinets are fully welded with 2mm steel. Each component has proven reliability, we design and manufacture in-house. Each cabinet is fully equipped with high quality components that both have been designed and tested by us for optimal performance., by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.