High Pressure Sand Blasting Cabinet

The high pressure blasting machine utilize a pressurized vessel that directly pushes the abrasives to the nozzle then blast onto the part's surface. This method accelerates the abrasive conveying and creates much more powerful blasting force.

Pressure Sand Blasting Cabinet Applications

Pressure blasting cabinet is extremely supportable for tough cleaning jobs, like remove heavy burrs, sharp edges, thick oxide layers and paintings that are difficult for suction blaster, moreover, large surface areas will be quickly cleaned with a pressure blaster. Pressure sandblast cabinet is also ideal for operating hard materials, like alloy wheels, marbles, stones, castings, car parts, etc.

High Pressure Sand Blasting Cabinet Features

Cabinet design, enclosed type without dust and abrasive leakage, cause to pollution to environment and protect users' health.

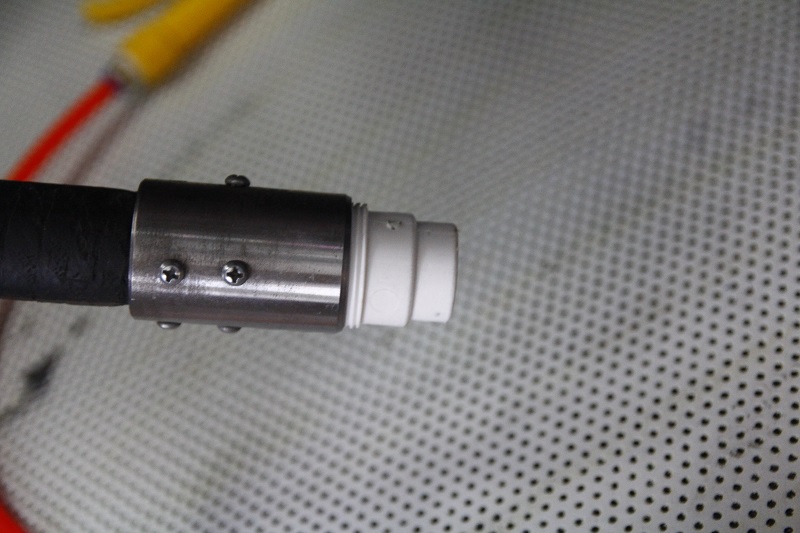

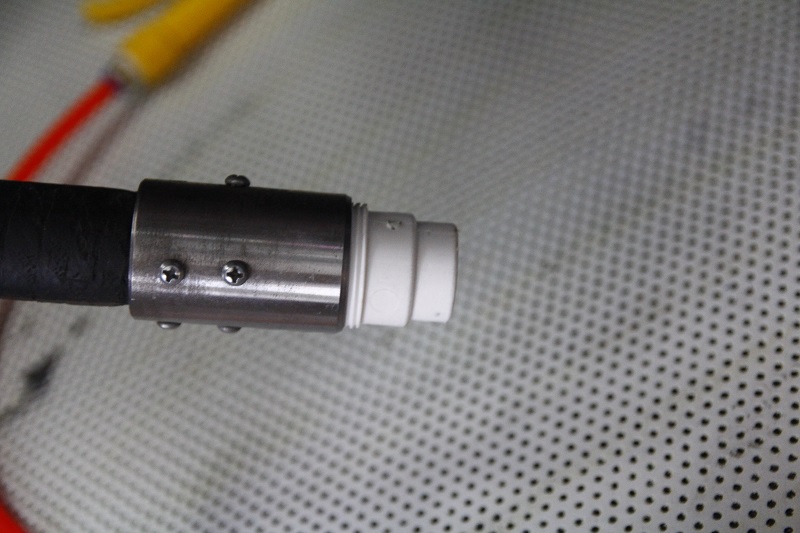

Configures a piece of aluminum casting sandblasting gun with boron carbide nozzle, as well as an air blowing gun for removing impregnated dusts.

The blast gun on/off is controlled via foot switch, and the pressure is regulator by valves at the front panel.

The advanced developed pressure abrasive valve improves processing quality and reduce the compressed air consumption.

Designed with a cartridge filter dust collector effectively removes dust, creates clear observation during blasting and ensures only dustless air discharged to the atmosphere.

Work Cabin

Sandblasting Gun

Air Blowing Gun

Pressure Regulators

Pressurized Pot

Dust Collector

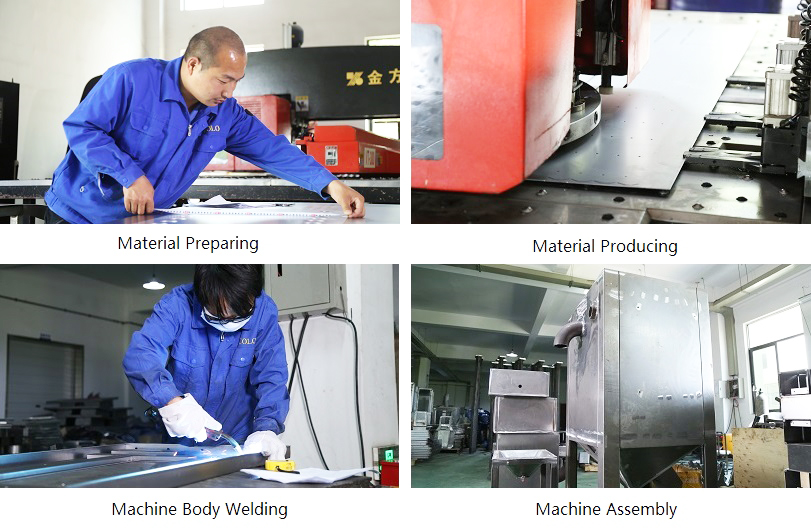

Custom-made Pressure Blast Cabinet

The size and configurations of pressure blast cabinet can be customized according to customer requirements, such as installing with turntable and loading cart for heavy duty products, or making with 2, 3, or 4 working cabins to operate oversized workparts.

Optional Turntable & Cart

2 Working Stations

High Pressure Sand Blasting Cabinet Specifications

Model

| KF-1010P |

| Outside Size | L1650*W1000*H21000mm |

| Cabin Size | L1000*W1000*H800mm |

| Max.Loading | 80-100kgs |

| Dust Collector Size | L430*W430*H1600mm |

| Pressure Tank | Diameter350mm, height450mm |

| Pressure Gauge | 2 pieces. |

| Number of gun | 1 set with boron carbide nozzle |

| Power supply | 110V/220V/380V/410V/450V/(50-60Hz), made as local. |

| Dust Collector motor | 0.55kw |

| Lighting | 18w fluorescent |

| Air source requirement:: | pressure 5-8bar (kg / square meter) |

Hot Sale Standard Modes of Pressure Sand Blasting Cabinet

| Model | Working Cabinet Size | Loading Capacity |

| KF-9080P | L900*W800*H800mm | 80-100kgs |

| KF-1010P | L1000*W1000*H800mm | 80-100kgs |

| KF-1212P | L1200*W1200*H800mm | 100-120kgs |