KF-1212P

Kafan

Pressure Sand Blasting Machine

| Availability: | |

|---|---|

Unlike suction blast cabinet, pressure blast cabinet utilizes a pressurized pot that directly pushes the abrasives to the gun then blast onto the target surfaces. This method accelerates the abrasive conveying and creates powerful cutting force.

The pressure sandblast cabinet is extremely supportable for tough blasting jobs, like remove heavy burrs, sharp edges, stripping heavy paintings that are difficult for suction blaster. The pressure blast cabinet can be configured with turntable and cart for easier operation when handing heavy objects.

Enclosed cabin desgn without dust leakage, cause to pollution to environment and protect users' health.

The advanced-developed pressure abrasive valve improves processing quality and reduce the compressed air consumption.

The pressure blast machine can be customized to installed with turntable and loading cart for heavy products.

Cartridge filter dust collector effectively removes dust, creating clear observation during blasting and ensures only dustless air vented back to the shop.

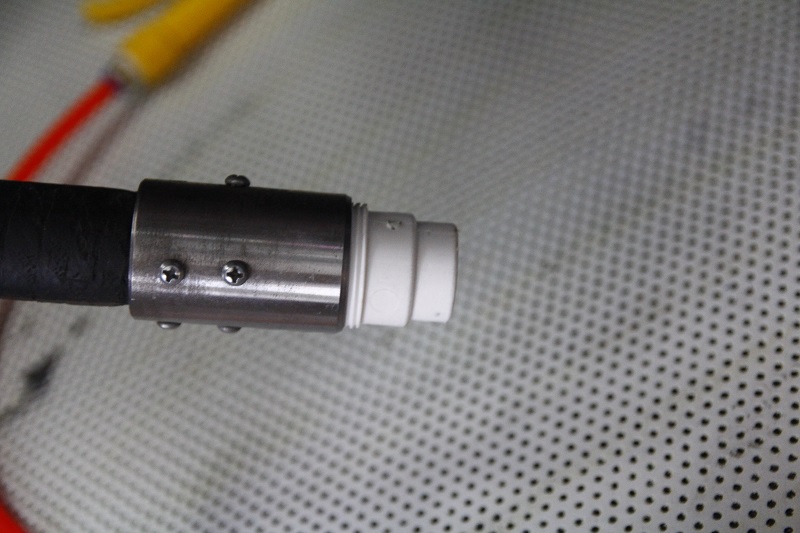

The blasting gun equipped with boron carbide nozzle, which is the most durable material in the market.

| Model | KF-1212P |

| Working Chamber Size | L1200*W1200*H800mm |

| Overall Size | L1650*W1200*H2100mm |

| Max.Loading | 100-120kgs |

| Dust Collector Size | L430*W430*H1600mm |

| Pressure Tank | Diameter350mm, height450mm |

| Pressure Gauge | 2 pieces. |

| Number of gun | 1 set with boron carbide nozzle |

| Machine Material | 2.0mm Cold-rolled Steel Plate Welded |

| Voltage | made as local. |

| Dust Collector motor | 0.55kw |

| Lighting | 18w fluorescent, 1pcs |

| Air source requirement:: | pressure 5-8bar (kg / square meter) |

| Model | Working Cabinet Size | Loading Capacity |

| KF-9080P | L900*W800*H800mm | 80-100kgs |

| KF-1010P | L1000*W1000*H800mm | 80-100kgs |

| KF-1212P | L1200*W1200*H800mm | 100-120kgs |

Unlike suction blast cabinet, pressure blast cabinet utilizes a pressurized pot that directly pushes the abrasives to the gun then blast onto the target surfaces. This method accelerates the abrasive conveying and creates powerful cutting force.

The pressure sandblast cabinet is extremely supportable for tough blasting jobs, like remove heavy burrs, sharp edges, stripping heavy paintings that are difficult for suction blaster. The pressure blast cabinet can be configured with turntable and cart for easier operation when handing heavy objects.

Enclosed cabin desgn without dust leakage, cause to pollution to environment and protect users' health.

The advanced-developed pressure abrasive valve improves processing quality and reduce the compressed air consumption.

The pressure blast machine can be customized to installed with turntable and loading cart for heavy products.

Cartridge filter dust collector effectively removes dust, creating clear observation during blasting and ensures only dustless air vented back to the shop.

The blasting gun equipped with boron carbide nozzle, which is the most durable material in the market.

| Model | KF-1212P |

| Working Chamber Size | L1200*W1200*H800mm |

| Overall Size | L1650*W1200*H2100mm |

| Max.Loading | 100-120kgs |

| Dust Collector Size | L430*W430*H1600mm |

| Pressure Tank | Diameter350mm, height450mm |

| Pressure Gauge | 2 pieces. |

| Number of gun | 1 set with boron carbide nozzle |

| Machine Material | 2.0mm Cold-rolled Steel Plate Welded |

| Voltage | made as local. |

| Dust Collector motor | 0.55kw |

| Lighting | 18w fluorescent, 1pcs |

| Air source requirement:: | pressure 5-8bar (kg / square meter) |

| Model | Working Cabinet Size | Loading Capacity |

| KF-9080P | L900*W800*H800mm | 80-100kgs |

| KF-1010P | L1000*W1000*H800mm | 80-100kgs |

| KF-1212P | L1200*W1200*H800mm | 100-120kgs |

Siphon Blaster VS Pressure Blaster, which do I choose?

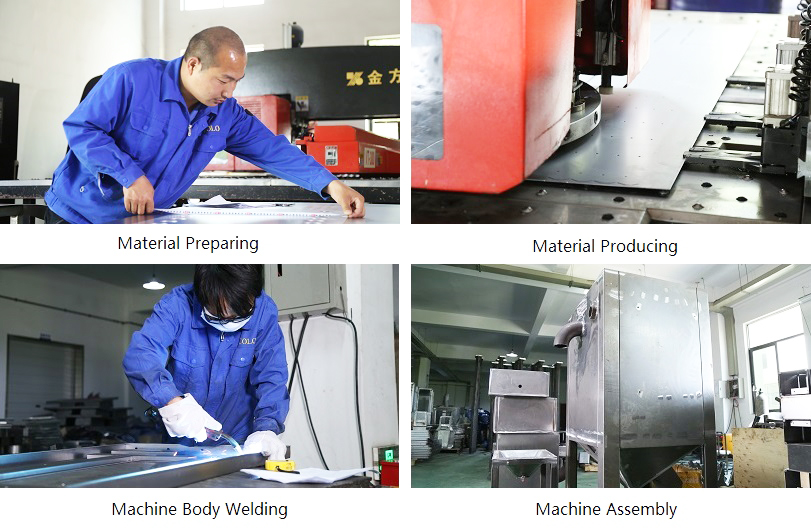

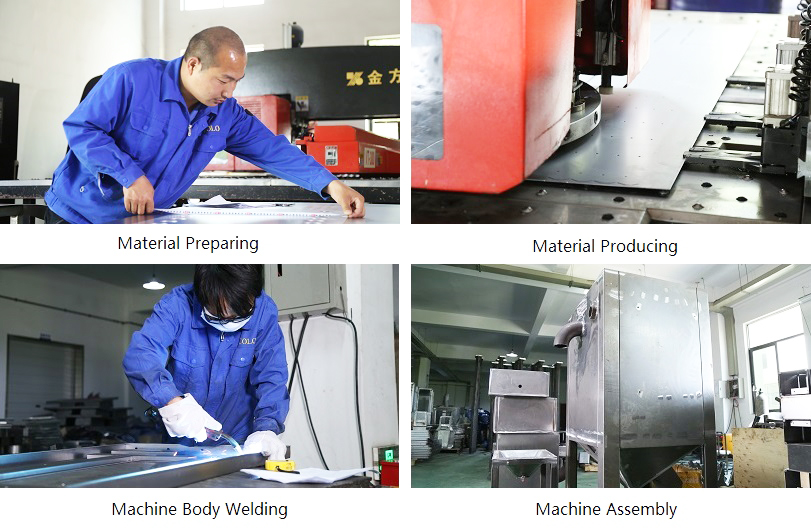

Devoted to world market for over 15 years, Kafan offer you factory-direct manufactured sand blasting machine in high quality and competitive price. With professional sales, techinical, production team, we provide blasting equipments in a variety of specifications and styles based on customers' requirements. Such as suction blast machine, pressure blast machine,portable blaster, wet blasting machine, automatic conveyor blast machine.

To pursue best performance, we use the latest technology for our blast components, our cabinets are fully welded with 2mm steel. Each component has proven reliability, we design and manufacture in-house. Each cabinet is fully equipped with high quality components that both have been designed and tested by us for optimal performance., by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.

Devoted to world market for over 15 years, Kafan offer you factory-direct manufactured sand blasting machine in high quality and competitive price. With professional sales, techinical, production team, we provide blasting equipments in a variety of specifications and styles based on customers' requirements. Such as suction blast machine, pressure blast machine,portable blaster, wet blasting machine, automatic conveyor blast machine.

To pursue best performance, we use the latest technology for our blast components, our cabinets are fully welded with 2mm steel. Each component has proven reliability, we design and manufacture in-house. Each cabinet is fully equipped with high quality components that both have been designed and tested by us for optimal performance., by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.