Rotary Table Automatic Sandblaster Machine for Cookware

This rotary table type automatic sandblaster is specially designed for cylindrical products, such as all kinds of cookware, aluminum pot, pan, baking tray, etc. It achieves continuous batch production with even surface effect and quality consistency.

How rotary table automatic sandblaster works?

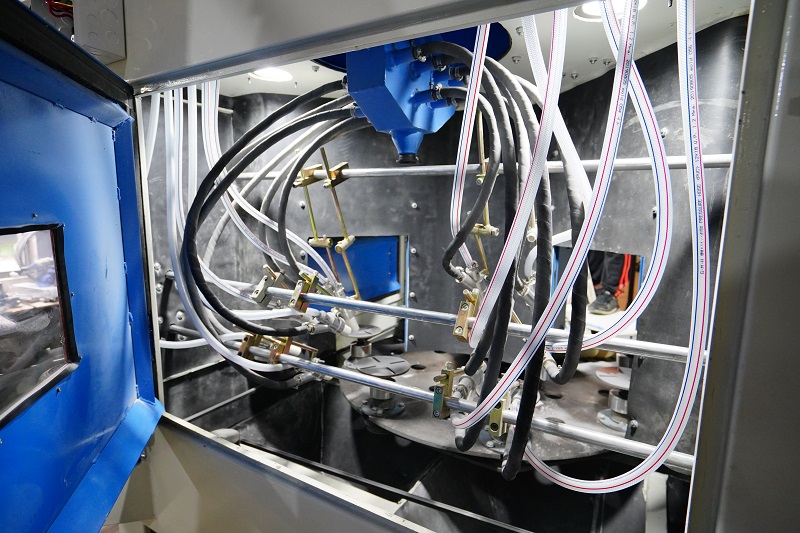

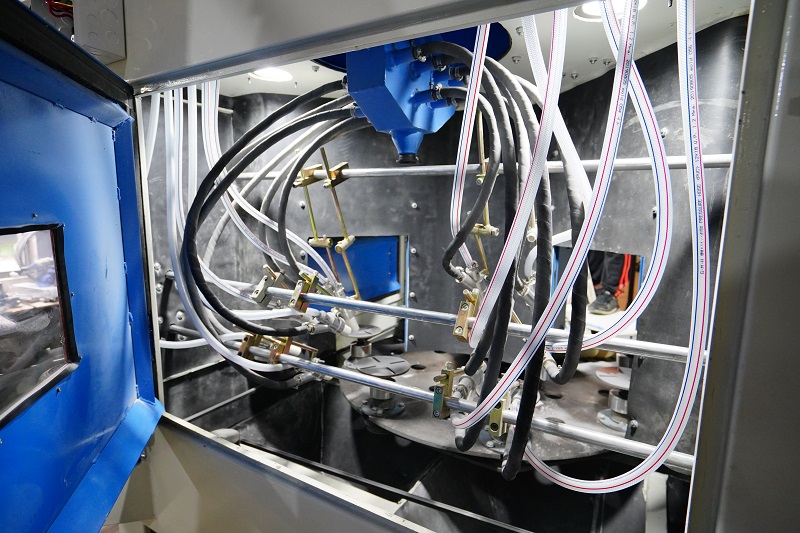

It is configured with an indexing turntable that fitted with a certain quality of evenly spaced small revolving stations which are clampped with workparts. The indexing table intermittently rotates to present the workparts in accurate position and for a precise amount of time in front of the blast guns for automatic processing.

Rotatory Table Automatic Sandblaster Features

1. Indexing table and small station rotates synchronously that ensures workparts are entirely cleaned.

2. The blast guns can be set for fixed blasting or swinging blasting with adjustable speed and angle.

3. Small working turntables drives through an independent motor, stepless speed regulation by converter

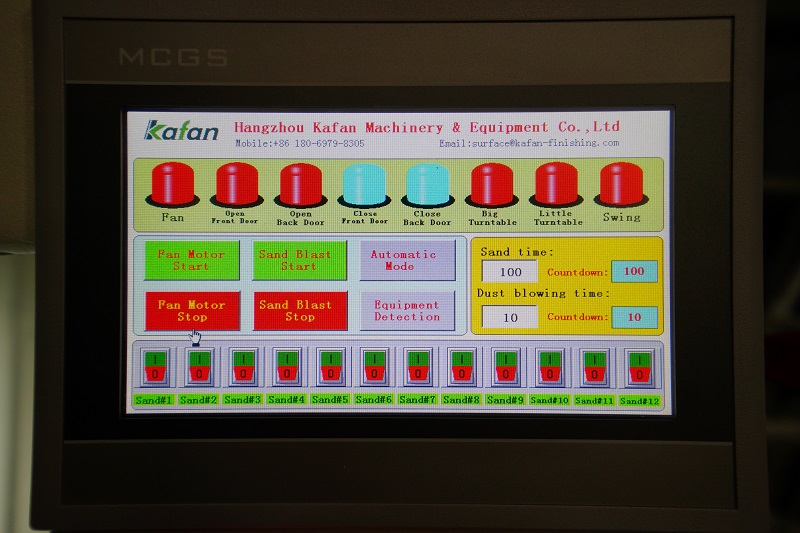

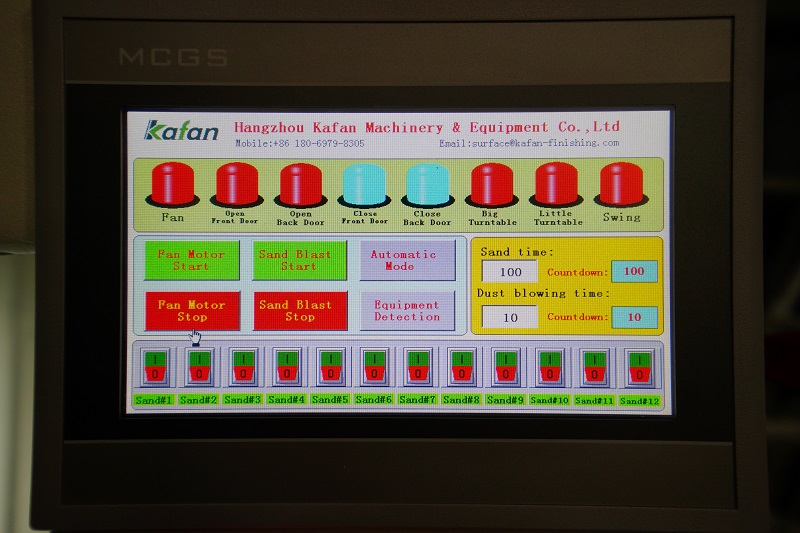

4. High automation and accuracy task controlled by PLC system, guarantee the balanced uniform blasting effect, as well as safe production

5. Specially fixtures can be customized for quick and solid clipping to improve efficiency.

6. Cyclone and cartridge filter unit are used to separate the dust from blasted abrasives and collect the dust to prevents air pollution.

Index Turntable

Small Turntables

Unloading Station

Cyclone Separator

Regulation Valves

Touch Control Panel

Rotating Table Automatic Sandblaster Machine Technical Parameters:

| Model: | KF-1719-12A |

| Overall Dimension | 1700x1900x2350mm |

| Dust Collector Size | 1400x1400x1700mm |

| Index Turntable Size | Dia 1400mm |

| Drive Motor Power | 1.1kw |

| Qty of Small Turntables | 12pcs |

Drive Motor Power

| 0.75kw |

| Max. Size of Parts Allowed | Dia 400mm x Height 450mm |

| Qty of Blast Guns | 8pcs |

| Blast Gun Nozzle | Durable Boron Carbide |

| Power Supply | 380V/220V As required |

| Separator Power | 5.5kw |

| Compressed Air Source | 2-8bar

|