Sandblasting Machine with Air Compressor, Freeze Dryer, Air Storage Tank

Complete Package to Start Your Sandblasting Application

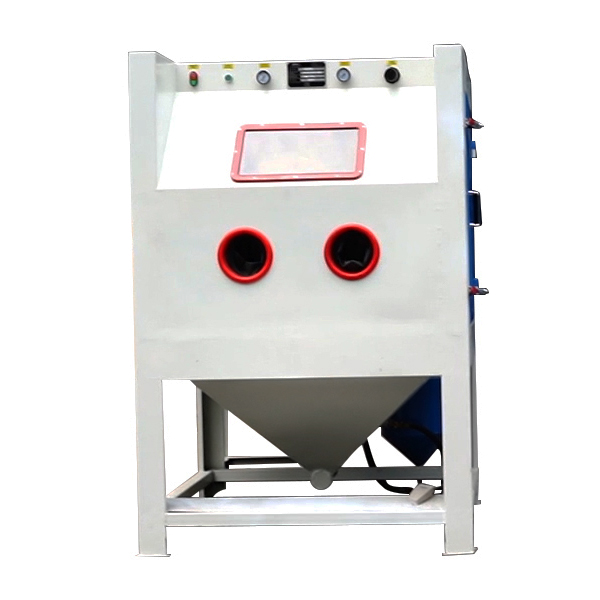

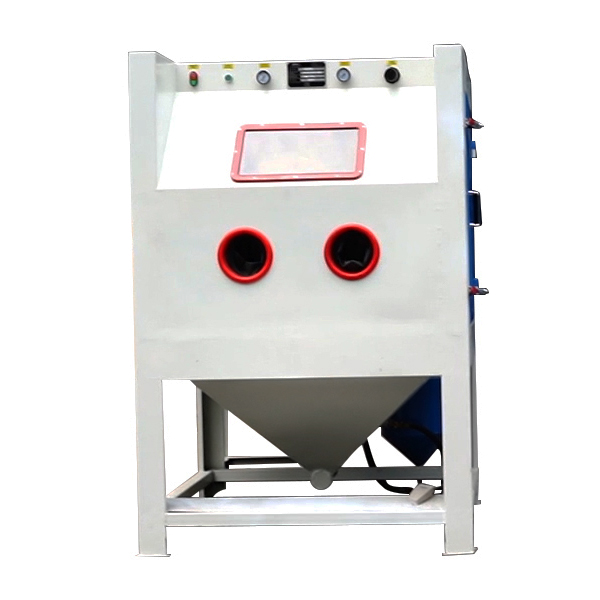

Sandblasting Machine

Sandblasting machine, for the purpose of surface treatment, such as removing rust and grease, stripping old paints, deburring or other decorating processes. We supply different sandblasters for your specific requirements, such as suction blast cabinet, wet sandblasting machine, pressure sandblasting machine, portable blaster, automatic sandblasting equipment.

Highly effective sandblasting requires clean, dry compressed air with stable and continuous supplying. Thus any pneumatic powered industrial process requires the compressed air station, including compressor, air dryer and air storage tank.

Air Compressor

Screw air compressors are best applied in applications that have a continuous air demand for larger industrial applications. With excellent features:

1)High efficiency and high reliability. The screw air compressor adopts a high-capacity compression assembly, and its rotor has a low speed of outer circle , reaching to best oil injection.

2)Least maintenance All components are designed for long life, with large inlet filters, oil filters and fine separators to ensure optimum compressed air quality.

3) Precision operation control. The screw compressor is equipped with a built-in intelligent control system whose control menu is easy to use.

Freeze Dryer

In the process of drying compressed air, the freeze dryer is to reduce the moisture in the compressed air by lowering the temperature. Mainly consists of drying cabin, condensers,freezing units, vacuum pumps, heating/cooling devices, etc

The freeze dryer has become the general tool for air drying and purification, widely used in various pneumatic powered processes, such as sandblasting, powder coating.

Air Storage Tank

It is a pressure vessel specially for storing compressed air. With the function of buffering, to stablely supply compressed ir and reduces the frequent start of compressor. At the same time, the sediment of compressed air at the tank is more benefit to dewatering and decontaminating.