Multi-station Large Sand Blast Cabinet

Multi-station sandblasting cabinet designed with three working positions allows one or more users operate at the same time, the large internal space will be ideal for oversized workpieces and increase treatment efficiency.

Kafan Multi-station Large Sand Blasting Cabinet Features

1. Our blast cabinet body is made of 2mm thick stainless steel with powder-coated surface, rigid and anti-rust.

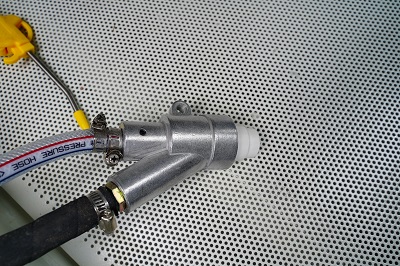

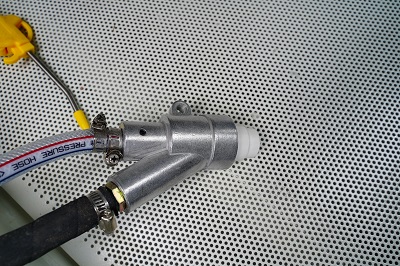

2. The blasting gun is aluminum alloy casting with boron carbide nozzle, durable and reducing fatigue of sandblasting operators.

3. Cartridge filter remove system effectively collect dust, and ensures only clean and dustless air discharged to the atmosphere.

4. A separator is optional to be configured if using ultra-fine abrasives.

5. Pressure regulators, filters, solenoid valves and other major components are high-quality brand, guarantee long lifespan.

6. There is an abrasive funnel at the bottom of the blast cabinet, used abrasives can be recycled to reduce consumption.

7. Foot pedal switch to control the work of blasting gun, which reduces the user's fatigue, facilitates the operation and ensures the safety.

Work Cabin

Blast Gun

Foot Control

Internal Lights

Filter Dust Collector

Separator (optional)

Three Station Large Sand Blasting Cabinet Specifications

| Model: | KF-2810-3 |

| Overall Dimension: | Length2800 * width1000 * Height750mm |

| Power: | 220V/380 50Hz/60Hz (customized) |

| Body plate thickness: | 2mm |

| Cabin lights | 220V 13W anti-riot lights |

| Separator motor: | 220V 50HZ 550W |

| Separator power: | 1.1KW |

| Separator air volume: | 4.5m3 / min |

| Work piece sandblasting gun: | 3 pieces |

| Compressed air source: | 3-8bar (kg / cm2) flow 0.6-1.0 cubic meters / min.

|

*This large sandblasting cabinet works on siphon principle which means a negative pressure created in the blast gun that sucks abrasives and blasts to the workpart surface, through a grinding action, the impurities, oxide layer, old paints are removed. We also supply large wet sandblasting cabinet for delicate finish, large pressure blast cabinet for quick cleaning jobs. Special sizes and designed can be customized as required.

Why choose kafan sandblasting cabinets:

1. Imported main components, steel plate welded body, high quality material, coated surface, anti-rust, durable and long lifespan.

2. One year warranty, any quality problems with the parts, we will provide replacement for free. (not including wearing parts)

3 Build wearing parts warehouse to facilitate customers who need replacements, offer customer equipment maintenance knowledge.

4. Free technical consulting services before and after sales, and provide equipment update information