KF-1610W-2

KAFAN

| Availability: | |

|---|---|

Double working station wet blasting cabinet is designed to operate long oversized workparts, and allows 2 operators working at same time, which increase working efficiency. The wet sandblasting cabinet is specially made of stainless steel plate to avoids geting rust, the powder coated surface makes it extremely durable and wear-resistent to ensures long life.

1. Machine body is made of stainless steel with coated surface, durable and anti-rust, inner chamber of the wet blatsing chamber has rubber lining, reducing jet shock.

2. High flow wet blasting gun with 8mm nozzle made of most wear-resistant material, boron carbide.

3. Can be configured with window washer or wiper ensuring clear view of blasting work.

4. Each blast gun on/off is controlled by foot pedal switch, safe and reliable.

5. A high performance pump highly mixes the abrasive and water into uniform slurry, you can add anti-rust agent to slurry in order not to get rust of metal parts.

6. Configured with a set of demister removing mister keeps a clear working view.

| Model: | KF-1610W |

| Overall Dimensions: | L1700*W1500*H2000mm |

| Working cabin size: | L1600*W1000*H800mm |

| Voltage | 220V/380V 50-60HZ, Voltage can be customized as local |

| Pump Motor | 3KW |

| Wet Blast Guns | 2 pcs, with boron carbide nozzle(8mm) |

Light: | 1*18w saving lamps |

Suitable abrasive: | Glass beads(for aluminum,stainless steel) Brown aluminum oxide(Steel or other) 80#-320# |

Feed abrasive: | 4-6kgs |

Abrasive: Water | 1:3 |

| Compressed air source: | 0.4-0.8Mbar |

Air flow required: | 0.5-1.1m3/min |

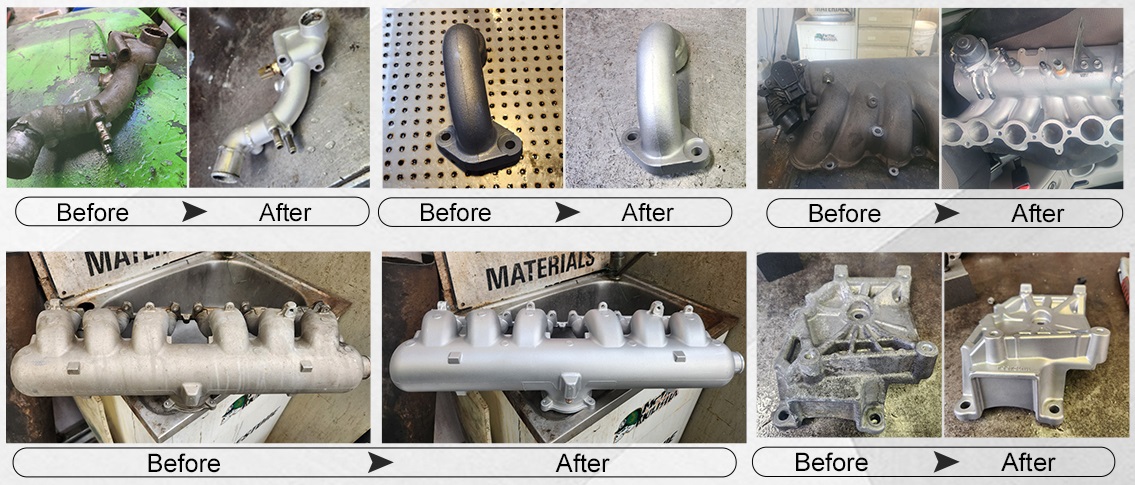

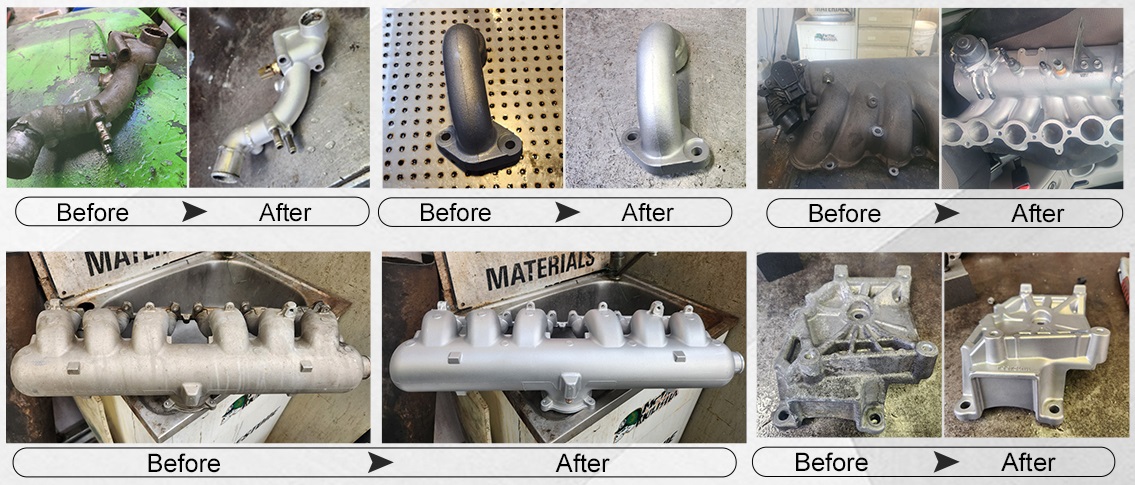

Wet blasting leaves the underlying component completely intact with its original dimensions, whilst removing the unwanted materials So it is rapidly expanding into many restoration sectors where quality and servicing is critical.

Perfect for motors, cylinder heads, sub-sea components, aviation parts, crank cases, wheel hubs, suspension parts, bolts, master cylinders, brake calipers and valuable restoration projects.

Effective for cleaning of dies and moulds, removal of pain, rust, scale, carbon and similar deposits.

Surface preparation prior to bonding, re-painting and powder coating.

Wet Blasting will also produce a very uniform satin finish especially on aluminium or stainess steel items returning the material to as new casting appearance

Finishing of stainless steel and other metals, cleaning of PCBs and electrical components and so on.

As the media material can be varied the gentle cleaning action of Aqua Blasting is not limited to metals and cleans exceptionally well with plastics and rubbers.

Double working station wet blasting cabinet is designed to operate long oversized workparts, and allows 2 operators working at same time, which increase working efficiency. The wet sandblasting cabinet is specially made of stainless steel plate to avoids geting rust, the powder coated surface makes it extremely durable and wear-resistent to ensures long life.

1. Machine body is made of stainless steel with coated surface, durable and anti-rust, inner chamber of the wet blatsing chamber has rubber lining, reducing jet shock.

2. High flow wet blasting gun with 8mm nozzle made of most wear-resistant material, boron carbide.

3. Can be configured with window washer or wiper ensuring clear view of blasting work.

4. Each blast gun on/off is controlled by foot pedal switch, safe and reliable.

5. A high performance pump highly mixes the abrasive and water into uniform slurry, you can add anti-rust agent to slurry in order not to get rust of metal parts.

6. Configured with a set of demister removing mister keeps a clear working view.

| Model: | KF-1610W |

| Overall Dimensions: | L1700*W1500*H2000mm |

| Working cabin size: | L1600*W1000*H800mm |

| Voltage | 220V/380V 50-60HZ, Voltage can be customized as local |

| Pump Motor | 3KW |

| Wet Blast Guns | 2 pcs, with boron carbide nozzle(8mm) |

Light: | 1*18w saving lamps |

Suitable abrasive: | Glass beads(for aluminum,stainless steel) Brown aluminum oxide(Steel or other) 80#-320# |

Feed abrasive: | 4-6kgs |

Abrasive: Water | 1:3 |

| Compressed air source: | 0.4-0.8Mbar |

Air flow required: | 0.5-1.1m3/min |

Wet blasting leaves the underlying component completely intact with its original dimensions, whilst removing the unwanted materials So it is rapidly expanding into many restoration sectors where quality and servicing is critical.

Perfect for motors, cylinder heads, sub-sea components, aviation parts, crank cases, wheel hubs, suspension parts, bolts, master cylinders, brake calipers and valuable restoration projects.

Effective for cleaning of dies and moulds, removal of pain, rust, scale, carbon and similar deposits.

Surface preparation prior to bonding, re-painting and powder coating.

Wet Blasting will also produce a very uniform satin finish especially on aluminium or stainess steel items returning the material to as new casting appearance

Finishing of stainless steel and other metals, cleaning of PCBs and electrical components and so on.

As the media material can be varied the gentle cleaning action of Aqua Blasting is not limited to metals and cleans exceptionally well with plastics and rubbers.