Automatic Wet Blasting Machine, Conveyor Belt Sandblaster

Wet type belt conveyor blasting system allows a batch of workparts continuously pass thru the processing chamber for automatic wet blasting, which ahieves efficient working with reduced time and labor. Our automatic sand blasting machine offers a versatoile solution allowing for most processing to be done automatically.

This stainless steel made automatic wet sandblaster incoperates a closed loop wet blasting system, delivering the unique benefits of slurry blasting technology with high quality finishing and cleaning purposes.

Automatic Wet Blasting Machine Working Cabin

1) Made of 3mm stainless teel plates with coated surfaces, which consists of a blasting station and a washing station separated by rubber curtains.

2) Installed with protective rubber plate in the inner wall to protect it from blasting splash that reduces wear.

3) Embedde with a door on the front of sandblasting cabin for monitoring, debugging and maintenance. If the door is not well-closed, a limited switch will control it not started to protect the safety of the operator.

4) An abrasive circulating funnel beneath the blasting cabin is to collect and store the abrasive slurry

6) Each working cabin is installed with top light for clear observation.

Stainless Steel Conveyor

Configured with a customized stainless steel conveyor belt, durable, anti-rust.

A motor drives the sprocket wheel that moves the conveyor belt in a circular motion to realize the input and output of the workpiece.

The conveying mechanism is driven by a 1.5KW variable frequency motor,

The speed of conveyor chain is ≤0.2m/s, frequency conversion adjustable.

Automatic Wet Blasting Guns

Configured with 12 sets of blast guns, the nozzle diameter is Φ8mm,

The blast guns are made of casting aluminum with a wear-resistant polyurethane layer inside, the spray nozzles are made of durable boron carbide material.

The distance and angle between guns and the workparts can be adjusted manually and then fixed.

The sspray gun swinging mechanism works through a variable frequency motor driving the connecting rod to drive the linear slide, which is extremely stable.

The moving intervals of the spray gun groups are different, so that the workparts can be accurately blasted and greatly improves processing efficiency.

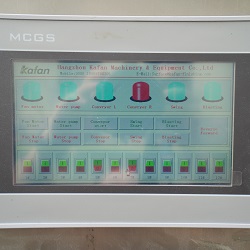

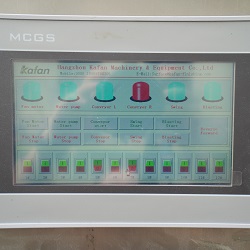

Wet Blasting Machine Control Sytsem

The automatic sandblaster applies advanced electric and pneumatic control system. PLC control system with touching screen offers easy-to-use interface, allows setting parameters and monitoring processing with a high degree of flexibility and reliability。

Slurry Pump

1) 7.5KW slurry pump applies UK AD company technology, features hIgh working pressure, reliable performance and easy maintenance.

2) Provided with agitating nozzles for slurry pump, agitates the recovered abrasives in the storage funnel to ensure consistent concentration of the delivered slurry from slurry pump.

Circulating cleaning and filtering system

Applies a circulating cleaning and filtration system taking full utilization of water and abrasive materials.

This system consists of a cleaning pump, a flocculation tank, a settling tank, a fine filter tank, and a water purification tank.

The workparts after sandblasting will be cleaned by rinsing water, so that the abrasives that adheres to the surface can be returned to the storage tank for participation in the circulation.

The blasted-abrasives sedimentates, flocculates for collection and recycling

The overflow slurry will be filtred in order to get recirculating pure water forming a closed loop system,

Automatic Wet Blasting Machine Specifications

| Model | KF-3208-12W |

| Working Size | 1200*1400*1100mm |

| Overall Size | 3200*1500*2000 mm |

| Voltage | Customized, 3 phase |

Slurry Pump Motor

| 7.5kw, 1 set |

| Conveyor Motor | 1.5kw, 1 set |

| Blast Gun Motor | 0.4kw, 1 set

|

| Dust Collector Fan Motor | 4kw, 1 set |

| Total Power | 14kw |

| Lighting | 2x20w |

| Compressed Air Requirment | >=0.7mpa, >=12m3/min |

| Air Consumption for Each Gun | 1.5m3/min |

| Blast Gun Qty | 12pcs |

| Blast Gun Nozzle | Boron Carbide Nozzle, Dia:8.5mm |

| Abrasive Ratio | 1:5~1:7 (dry abrasive : water) |

Why Choose Kafan Automatic Sandblasting Systems?

1. High productivity and automation, reduced labor and time.

2. Batch processing increase quality consistency, avoids the uneven blasting effect, chromatic aberration and quality problem.

3. The blasting machine can be designed according to workparts of different sizes, different shapes and different finishing requirements.

4. Made of stainless steel materials with coated surface, and built with quality imported components, which maximize working performance.