Wet Sandblasting Machine, Dustless Blasting Cabinet

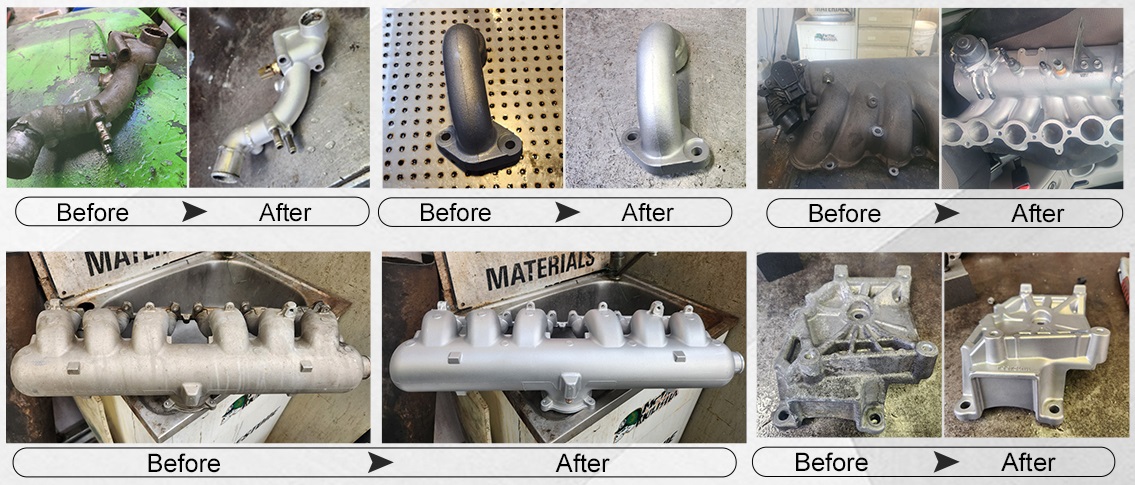

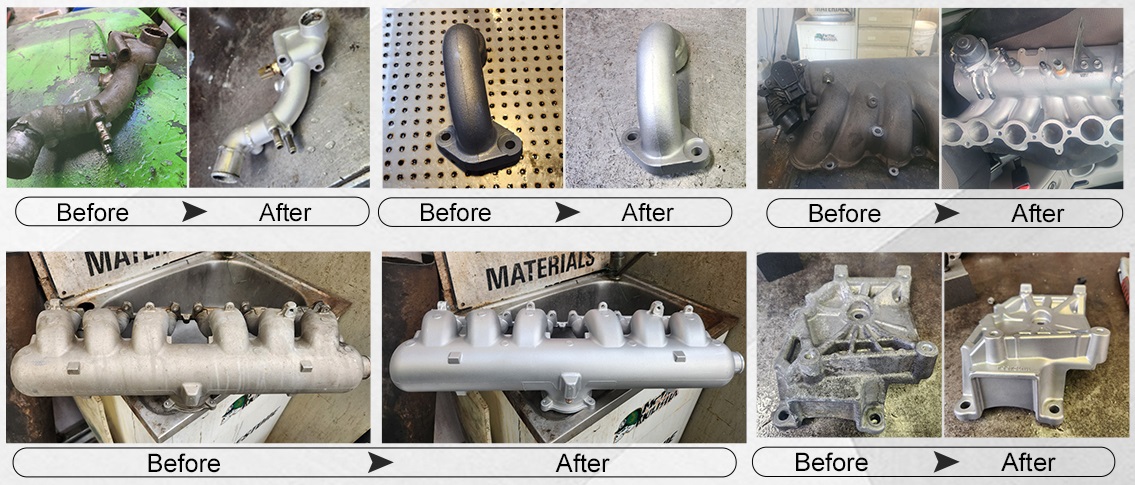

Wet sandblastng machine use a high performance pump agitating water and abrasive into slurry mixture, then blast onto targets attaining the purpose of removing rust, oxide layer, and other contaminants. Kafan wet blasting machine is the initial choice for applications requiring the highest quality of surface finish, an innovative and popular mode in surface finishing industry.

Wet sand blasting machine has obvious advantages over dry blasting machines

1. With water's lubrication the surface performs much brighter and cleaner, without abrasive impregnation.

2. Wet blasting process using fine abrasives tends to operate delicate or fragile products ideally, such as precise instruments and accessories.

3. More important, wet blasting equipment creates dustless working chamber and have a clear observation during processing.

4. Water sandblasting has a cushion effect that minimize the damage and wear of the blasting machine and parts.

5. Wet blasting decreases the friction heat to prevent color changes for some special metal workpieces.

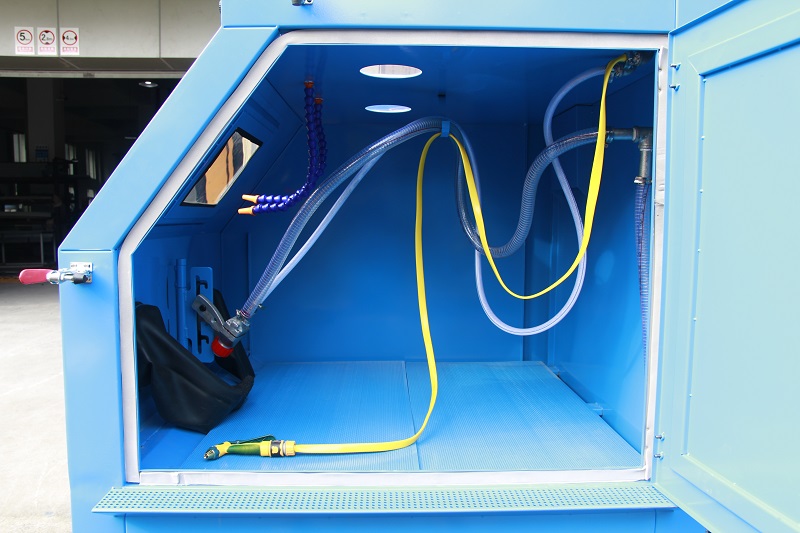

Kafan Wet Sand Blasting Machine Standard Configurations

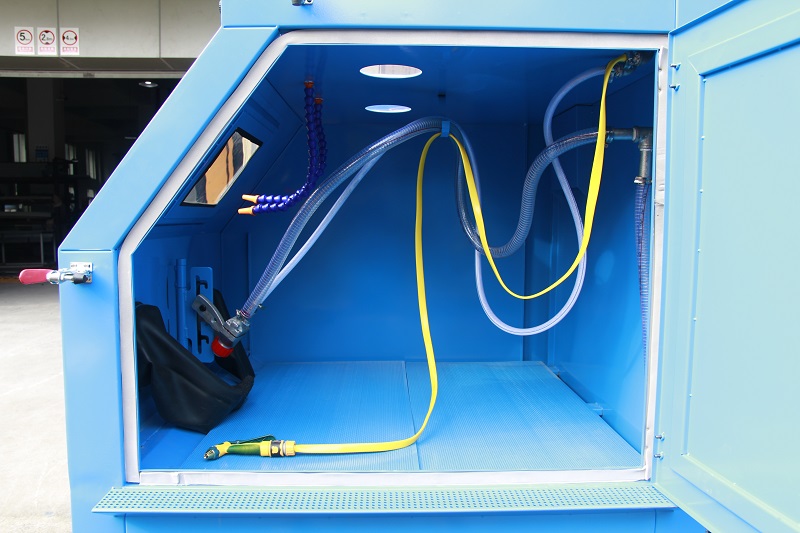

Made of 3mm thick stainless steel with powder-coated surface, rigid and anti-rust.

There is screen washer installed in the glass window keeping a clear view during the wet blasting

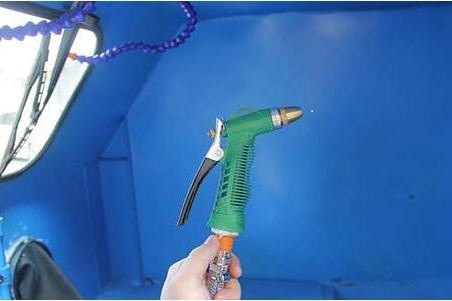

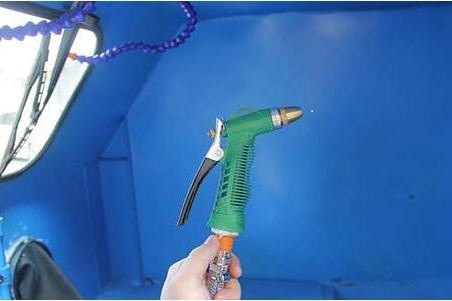

A high-flow wet blast gun with 8mm boron carbide nozzles specially for wet blasting process

A water gun to flush the residual dusts and abrasives, obtaining clean surfaces

An additional demister ensures higher quality working conditions.

A high performance slurry pump delivering highest mixture of abrasive and water.

Kafan Wet Sand Blasting Machine Optional Configurations

Water Recirculating System

The closed loop system has a recirculating tank interconnected to the slurry hopper, the blasted slurry mixture will be transferred to the tank for separating of water and abrasive. which is filtered by precise filter paper and rinsing tank.

A skimmer is configured to remove floating oil or grease.

If in your workshop running water is not available there, or worrying about waste water disposal, a closed loop wet blast cabinet is a good choice.

Heavy-duty Turntable

The wet blasting cabin can be added with a heavy-duty turntable for easily operating larger, heavier, complex components, giving operators an easy access to clean surfaces and corners.

The heavy-duty turntable loading the workparts is easy to move inside and outside across the track assembly, also can be configured with a cart making it convenient to transport the tools.

Wet Sand Blasting Machine Specifications:

| Model | KF-1010W |

| Outer size | L1300*W1600*H2000mm |

| Working area | L1000*W1000*H800mm |

| Loading Capacity | 50-80kgs |

| Motor | 2.2Kw |

| Air requirement | flow 0.5-1.1m^3/min |

| Light | 2*18w saving lamps |

| Blast Gun | 1 pc of wet blast gun with 1 boron cabide nozzle (8mm) |

| Air consumption for 1 gun | 0.4-0.8Mbar |

| Volume of abrasive & water | 25L |

| Feed abrasive | 4-6kg |

| Abrasive : Water | 1:3 |

| Voltage | 380V/220V 3 phase (customized) |

Popular Standard Models of Wet Sand Blasting Machines

| Model | KF-1212W | KF-1010W | KF-9080W | KF-6868W |

| Working size | 1200*1200*800mm | 1000*1000*800mm | 900*900*800mm | 600*600*500mm |

| Weight | 350kgs | 300kgs | 280kgs | 200kgs |

| Loading Capacity | 80-120kgs | 50-80kgs | 30-50kgs

| 20-30kgs

|

Wet Sand Blasting Machine Application:

Wet sandblasting machine is an innovative sandblasting equipment, a significant revolution in sandblasting industry, it was deeply welcomed and recognized by the users as soon as it came out.

As the excellent feature of delicate finishing, it can be widely used for precise parts, such as aerospace, electronics, weapons industry, automation, optics and other instrumentation industries; machine tools, molds, hydraulic parts, hardware tools, cars, tractors, motorcycles, power machinery, train locomotives and other factories, textile machinery parts, medical equipment parts, chemical machinery, metal materials, artificial crystals, springs, metal processing industry, dental, jewelry, watches, clocks, glasses and other high precision requirement industries.