KF-9080W

kafan

| Availability: | |

|---|---|

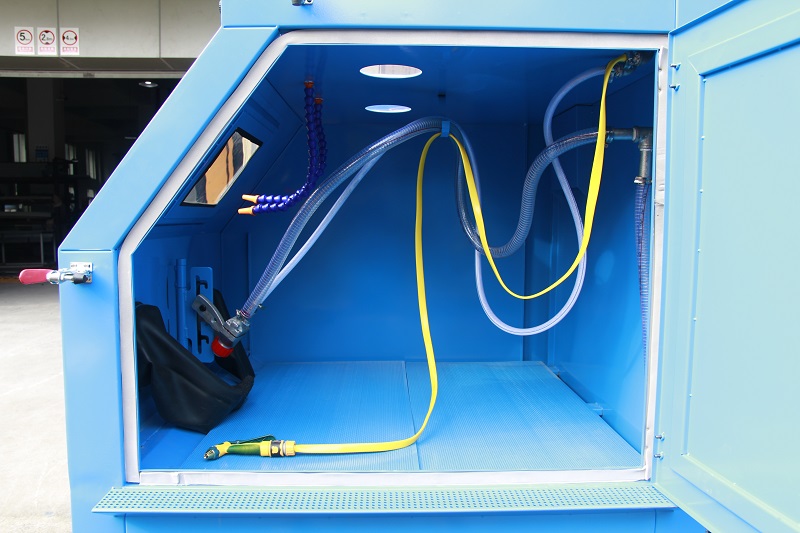

In the wet blasting process, abrasive media is mixed with water in a slurry pump. The pump deliver the mixture to the blasting gun while compressed air is to be the accelerate power.

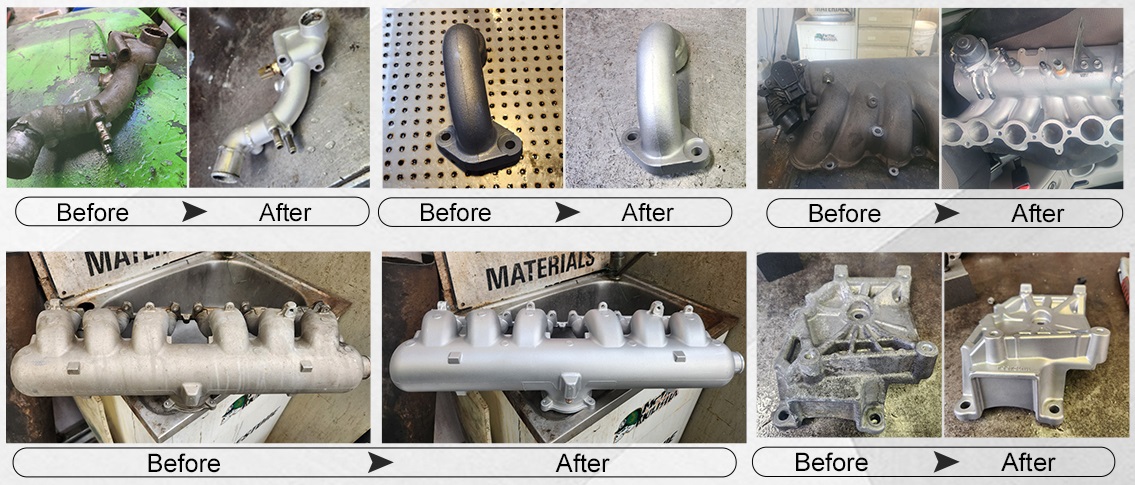

When it's used to clean a surface, the blasting grit eliminates the rust, oxides or unwanted coatings, at the same time the water washes them away. When it's used to finish a surface, the abrasive smooths down the surface and the water softens it blow.

1. When doing removing process, the water is washing off the media impregnation and stripped materials. Thus you're doing the treatment and cleanup all in one go.

2. Decrease the friction heat generated during the blasting in order to prevent color change of workpieces.

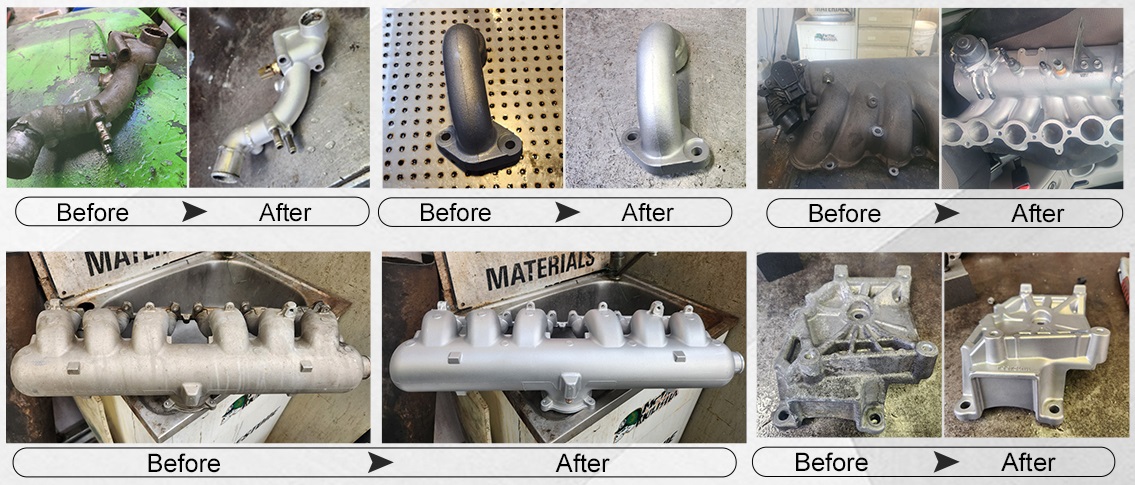

3. Creates more gentle surface removal without any damage of original profiles, an ideal tool to finish precise or delicate workparts, such as auto parts.

4. Wet slurry blasting will minimize the wear and damage caused to the wet blasting machine and the abrasives, increase the recycling rate.

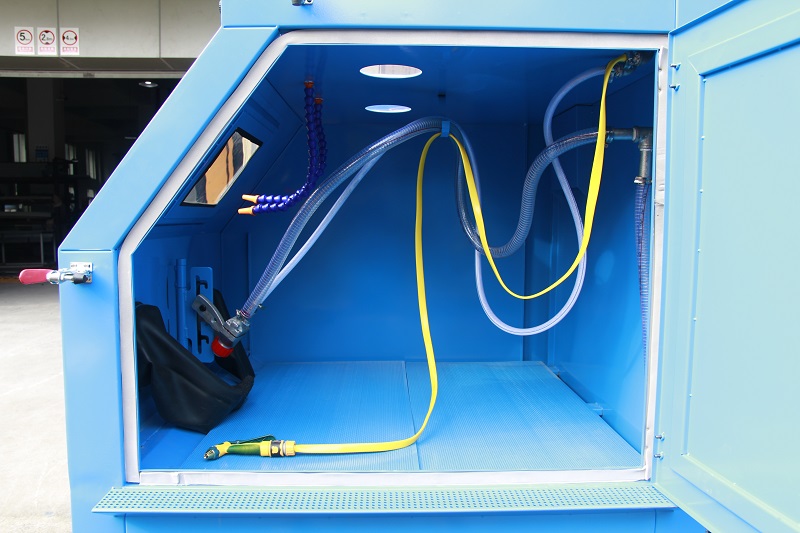

Water Recirculating System

The closed loop system has a recirculating tank interconnected to the slurry hopper, the blasted slurry mixture will be transferred to the tank for separating of water and abrasive. which is filtered by precise filter paper and rinsing tank.

A skimmer is configured to remove floating oil or grease.

If in your workshop running water is not available there, or worrying about waste water disposal, a closed loop wet blast cabinet is a good choice.

Heavy-duty Turntable

Can be added with a turntable for easily handling larger, heavier, complex components, such as alloy wheels, molds, castings, giving operators an easy access to clean surfaces and corners. The turntable can be set manual or automatic rotating.

Can be added with a cart, as the heavy-duty turntable loading the workparts is easy to move inside and outside across the cart track assembly, and the cart making it convenient to transport the tools outside.

| Model | KF-9080W |

| Outer size | 1000*1200*2000mm |

| Working area | 900*900*800mm |

| Weigth | 280kgs |

| Loading | 30-50kgs |

| Motor | 2.2Kw |

| Air requirement | flow 0.5-1.1m^3/min |

| Light | 2*18w saving lamps |

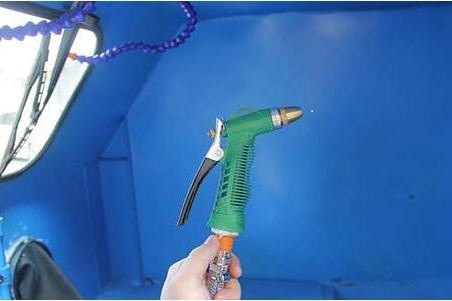

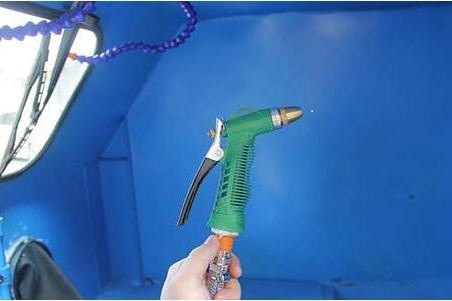

| Blast Gun | 1 pc of wet blast gun with 1 boron cabide nozzle (8mm) |

| Air consumption for 1 gun | 0.4-0.8Mbar |

| Volume of abrasive & water | 25L |

| Suitable abrasive | Glass beads(for aluminum, stainless steel) Brown Aluminum Oxide(stell or other)80#-320# |

| Feed abrasive | 4-6kg |

| Abrasive : Water | 1:3 |

| Voltage | 380V/220V 3 phase (customized) |

| Model | KF-1212W | KF-1010W | KF-9080W | KF-6868W |

| Working size | 1200*1200*800 mm | 1000*1000*800 mm | 900*900*800 mm | 600*600*500 mm |

| Weight | 350kgs | 300kgs | 280kgs | 200kgs |

| Loading Capacity | 80-120kgs | 50-80kgs | 30-50kgs | 20-30kgs |

Wet sandblasting machine is an innovative sandblasting equipment, a significant revolution in sandblasting industry, it was deeply welcomed and recognized by the users as soon as it came out.

As the excellent feature of delicate finishing, it can be widely used for precise parts, such as aerospace, electronics, weapons industry, automation, optics and other instrumentation industries; machine tools, molds, hydraulic parts, hardware tools, cars, tractors, motorcycles, power machinery, train locomotives and other factories, textile machinery parts, medical equipment parts, chemical machinery, metal materials, artificial crystals, springs, metal processing industry, dental, jewelry, watches, clocks, glasses and other high precision requirement industries.

In the wet blasting process, abrasive media is mixed with water in a slurry pump. The pump deliver the mixture to the blasting gun while compressed air is to be the accelerate power.

When it's used to clean a surface, the blasting grit eliminates the rust, oxides or unwanted coatings, at the same time the water washes them away. When it's used to finish a surface, the abrasive smooths down the surface and the water softens it blow.

1. When doing removing process, the water is washing off the media impregnation and stripped materials. Thus you're doing the treatment and cleanup all in one go.

2. Decrease the friction heat generated during the blasting in order to prevent color change of workpieces.

3. Creates more gentle surface removal without any damage of original profiles, an ideal tool to finish precise or delicate workparts, such as auto parts.

4. Wet slurry blasting will minimize the wear and damage caused to the wet blasting machine and the abrasives, increase the recycling rate.

Water Recirculating System

The closed loop system has a recirculating tank interconnected to the slurry hopper, the blasted slurry mixture will be transferred to the tank for separating of water and abrasive. which is filtered by precise filter paper and rinsing tank.

A skimmer is configured to remove floating oil or grease.

If in your workshop running water is not available there, or worrying about waste water disposal, a closed loop wet blast cabinet is a good choice.

Heavy-duty Turntable

Can be added with a turntable for easily handling larger, heavier, complex components, such as alloy wheels, molds, castings, giving operators an easy access to clean surfaces and corners. The turntable can be set manual or automatic rotating.

Can be added with a cart, as the heavy-duty turntable loading the workparts is easy to move inside and outside across the cart track assembly, and the cart making it convenient to transport the tools outside.

| Model | KF-9080W |

| Outer size | 1000*1200*2000mm |

| Working area | 900*900*800mm |

| Weigth | 280kgs |

| Loading | 30-50kgs |

| Motor | 2.2Kw |

| Air requirement | flow 0.5-1.1m^3/min |

| Light | 2*18w saving lamps |

| Blast Gun | 1 pc of wet blast gun with 1 boron cabide nozzle (8mm) |

| Air consumption for 1 gun | 0.4-0.8Mbar |

| Volume of abrasive & water | 25L |

| Suitable abrasive | Glass beads(for aluminum, stainless steel) Brown Aluminum Oxide(stell or other)80#-320# |

| Feed abrasive | 4-6kg |

| Abrasive : Water | 1:3 |

| Voltage | 380V/220V 3 phase (customized) |

| Model | KF-1212W | KF-1010W | KF-9080W | KF-6868W |

| Working size | 1200*1200*800 mm | 1000*1000*800 mm | 900*900*800 mm | 600*600*500 mm |

| Weight | 350kgs | 300kgs | 280kgs | 200kgs |

| Loading Capacity | 80-120kgs | 50-80kgs | 30-50kgs | 20-30kgs |

Wet sandblasting machine is an innovative sandblasting equipment, a significant revolution in sandblasting industry, it was deeply welcomed and recognized by the users as soon as it came out.

As the excellent feature of delicate finishing, it can be widely used for precise parts, such as aerospace, electronics, weapons industry, automation, optics and other instrumentation industries; machine tools, molds, hydraulic parts, hardware tools, cars, tractors, motorcycles, power machinery, train locomotives and other factories, textile machinery parts, medical equipment parts, chemical machinery, metal materials, artificial crystals, springs, metal processing industry, dental, jewelry, watches, clocks, glasses and other high precision requirement industries.

Kafan Services

1.Sample testing, we are glad that customers send us a sample workpiece to us for testing the finishing results before order.

2.One year warranty, any quality problems with the parts, we will provide replacement for free. (not including wearing parts

3 Build wearing parts of wet blasting cabinet warehouse to facilitate customers who need replacements.

4.Free technical consulting services before and after sales, offer customer equipment maintenance knowledge.

Packing & Delivery

Film and foam packing first, with wooden case outside packing.

Kafan Services

1.Sample testing, we are glad that customers send us a sample workpiece to us for testing the finishing results before order.

2.One year warranty, any quality problems with the parts, we will provide replacement for free. (not including wearing parts

3 Build wearing parts of wet blasting cabinet warehouse to facilitate customers who need replacements.

4.Free technical consulting services before and after sales, offer customer equipment maintenance knowledge.

Packing & Delivery

Film and foam packing first, with wooden case outside packing.

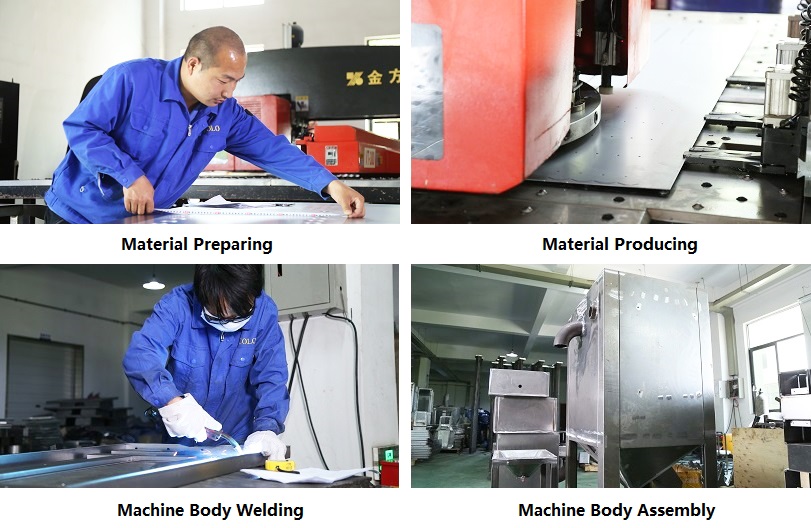

Devoted to world market for over 15 years, Kafan offer you factory-direct manufactured sand blasting machine in high quality and competitive price. With professional sales and production team, we produce sand blasting equipments in a variety of specifications and styles based on customers' requirements.

Located in Hangzhou, China, we we own a manufacturing base of 3600 square meter, around 100 employees and 24 sets production equipment, dividing into technical department, sales department, after-sale department, production department, QC department, manage and finance department, etc. As a fast growing company in supplying sandblasting equipment and mass finishing equipment, we devoted all ourselves to offering solution for any surface finishing problems.

Our products can be divided into two main parts, sandblasting equipment and mass finishing machines.

Sandblasting equipment including: manual sandblasting machine, suction sand blast cabinet, pressure blasting machine, wet abrasive blasting equipment, portable blaster pot, automatic conveyor blast system, tumbler blaster, rotary table blast machine, crawl blast machine.

Mass finishing system including: vibratory polishing & deburring bowl, vibratory bowl with separator, centrifugal barrel tumbling machine, centrifugal disc finishing system, mass finishing media.

We offer service: Standard Production Models, Customized Design, Before-order Technical Support, Engineer Oversea Installing & Training, Free Sample Testing, 24 hour On-line Consulting, ODM, OEM.

Devoted to world market for over 15 years, Kafan offer you factory-direct manufactured sand blasting machine in high quality and competitive price. With professional sales and production team, we produce sand blasting equipments in a variety of specifications and styles based on customers' requirements.

Located in Hangzhou, China, we we own a manufacturing base of 3600 square meter, around 100 employees and 24 sets production equipment, dividing into technical department, sales department, after-sale department, production department, QC department, manage and finance department, etc. As a fast growing company in supplying sandblasting equipment and mass finishing equipment, we devoted all ourselves to offering solution for any surface finishing problems.

Our products can be divided into two main parts, sandblasting equipment and mass finishing machines.

Sandblasting equipment including: manual sandblasting machine, suction sand blast cabinet, pressure blasting machine, wet abrasive blasting equipment, portable blaster pot, automatic conveyor blast system, tumbler blaster, rotary table blast machine, crawl blast machine.

Mass finishing system including: vibratory polishing & deburring bowl, vibratory bowl with separator, centrifugal barrel tumbling machine, centrifugal disc finishing system, mass finishing media.

We offer service: Standard Production Models, Customized Design, Before-order Technical Support, Engineer Oversea Installing & Training, Free Sample Testing, 24 hour On-line Consulting, ODM, OEM.