KF-9080W

Kafan

| Availability: | |

|---|---|

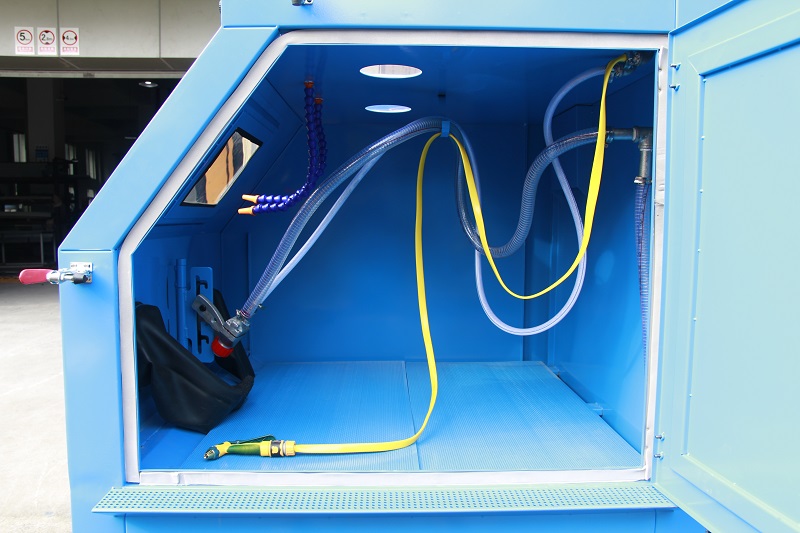

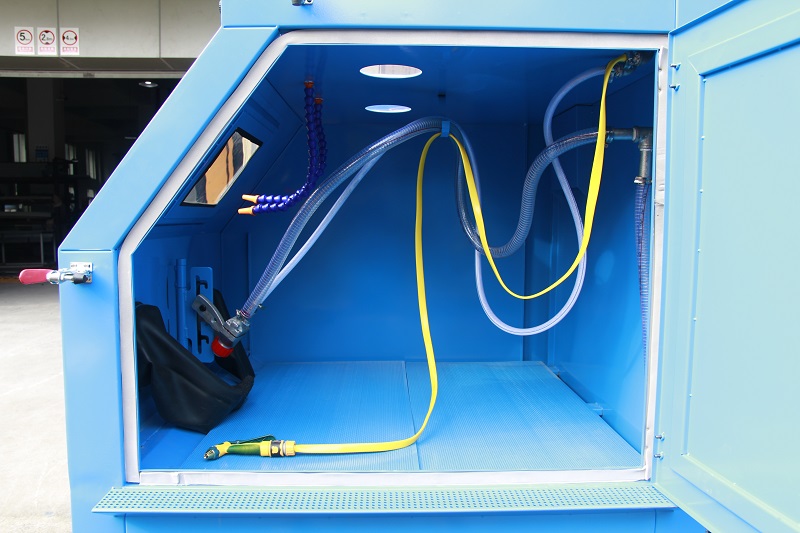

Our wet sandblasting cabinet designed with a high performance slurry pump that fully agitates water and abrasive, powerfully delivers the slurry mixture to targe surfaces through blast nozzles, as compressor air accelerate the travelling. attaining the purpose of removing rust, grease, oxide layer, scratchers or other contaminants.

Thanks to the water's flushing action it causes no media impregnation and creates cleaner surfaces.

The bringing of water eliminates the dust and increases the visibility of working chamber

Wet blasting delivers gentle but effective force for surface removal, suitable for delicate art crafts, or precise tools.

Water' s buffering action reduce the broken to abrasives, and minimize wear to the equipment, saves production cost in long term.

Water Recirculating System

The closed loop system has a recirculating tank interconnected to the slurry hopper.

The blasted slurry mixture will be transferred to the tank for separating of water and abrasive. which is filtered by precise filter paper and rinsing tank.

If in your workshop running water is not available there, or worrying about waste water disposal, a closed loop wet blast cabinet is a good choice.

Heavy-duty Turntable

The wet blasting cabin can be added with a heavy-duty turntable for easily operating larger, heavier, complex components, giving operators an easy access to clean surfaces and corners.

The heavy-duty turntable loading the workparts is easy to move inside and outside across the track assembly.

It also can be configured with a cart making it convenient to transport the tools in and outside of the cabinet.

| Model | KF-9080W |

| Outer size | 1300*1600*2000mm |

| Working area | 900*800*800mm |

| Motor | 1000*1200*2000mm |

| Air requirement | flow 0.5-1.1m^3/min |

| Light | 1*18w saving lamps |

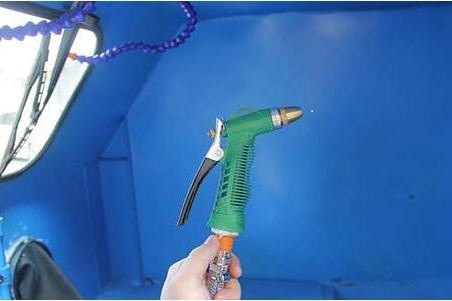

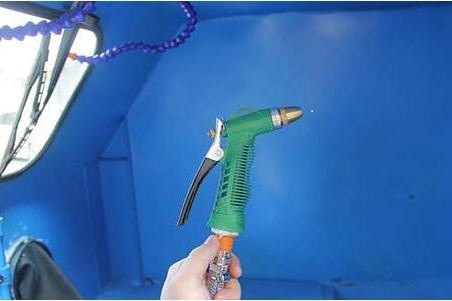

| Blast Gun | 1 pc of wet blast gun with 1 boron cabide nozzle (8mm) |

| Air consumption for 1 gun | 0.4-0.8Mbar |

| Volume of abrasive & water | 25L |

| Suitable abrasive | Glass beads(for aluminum, stainless steel) Brown Aluminum Oxide(stell or other)80#-320# |

| Feed abrasive | 4-6kg |

| Abrasive : Water | 1:3 |

| Voltage | 380V/220V 3 phase (customized) |

| Model | KF-1610 W(double gun) | KF-1212W | KF-1010W | KF-9080W |

| Working size | 1600*1000*800mm | 1200*1200*600mm | 1000*1000*800mm | 900*800*800mm |

| Weight | 320kgs | 350kgs | 300kgs | 280kgs |

| Loading | 100-140kgs | 80-120kgs | 50-80kgs | 30-50kgs |

Other custom sizes pls contact with us!

Our wet sandblasting cabinet designed with a high performance slurry pump that fully agitates water and abrasive, powerfully delivers the slurry mixture to targe surfaces through blast nozzles, as compressor air accelerate the travelling. attaining the purpose of removing rust, grease, oxide layer, scratchers or other contaminants.

Thanks to the water's flushing action it causes no media impregnation and creates cleaner surfaces.

The bringing of water eliminates the dust and increases the visibility of working chamber

Wet blasting delivers gentle but effective force for surface removal, suitable for delicate art crafts, or precise tools.

Water' s buffering action reduce the broken to abrasives, and minimize wear to the equipment, saves production cost in long term.

Water Recirculating System

The closed loop system has a recirculating tank interconnected to the slurry hopper.

The blasted slurry mixture will be transferred to the tank for separating of water and abrasive. which is filtered by precise filter paper and rinsing tank.

If in your workshop running water is not available there, or worrying about waste water disposal, a closed loop wet blast cabinet is a good choice.

Heavy-duty Turntable

The wet blasting cabin can be added with a heavy-duty turntable for easily operating larger, heavier, complex components, giving operators an easy access to clean surfaces and corners.

The heavy-duty turntable loading the workparts is easy to move inside and outside across the track assembly.

It also can be configured with a cart making it convenient to transport the tools in and outside of the cabinet.

| Model | KF-9080W |

| Outer size | 1300*1600*2000mm |

| Working area | 900*800*800mm |

| Motor | 1000*1200*2000mm |

| Air requirement | flow 0.5-1.1m^3/min |

| Light | 1*18w saving lamps |

| Blast Gun | 1 pc of wet blast gun with 1 boron cabide nozzle (8mm) |

| Air consumption for 1 gun | 0.4-0.8Mbar |

| Volume of abrasive & water | 25L |

| Suitable abrasive | Glass beads(for aluminum, stainless steel) Brown Aluminum Oxide(stell or other)80#-320# |

| Feed abrasive | 4-6kg |

| Abrasive : Water | 1:3 |

| Voltage | 380V/220V 3 phase (customized) |

| Model | KF-1610 W(double gun) | KF-1212W | KF-1010W | KF-9080W |

| Working size | 1600*1000*800mm | 1200*1200*600mm | 1000*1000*800mm | 900*800*800mm |

| Weight | 320kgs | 350kgs | 300kgs | 280kgs |

| Loading | 100-140kgs | 80-120kgs | 50-80kgs | 30-50kgs |

Other custom sizes pls contact with us!

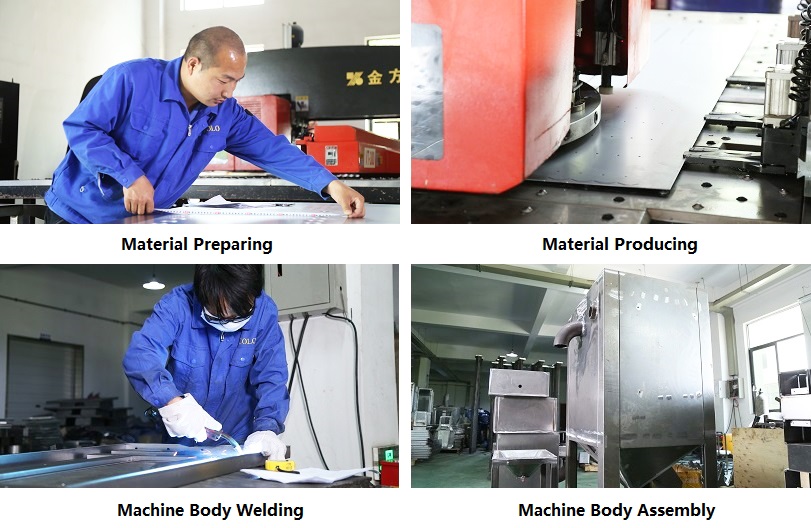

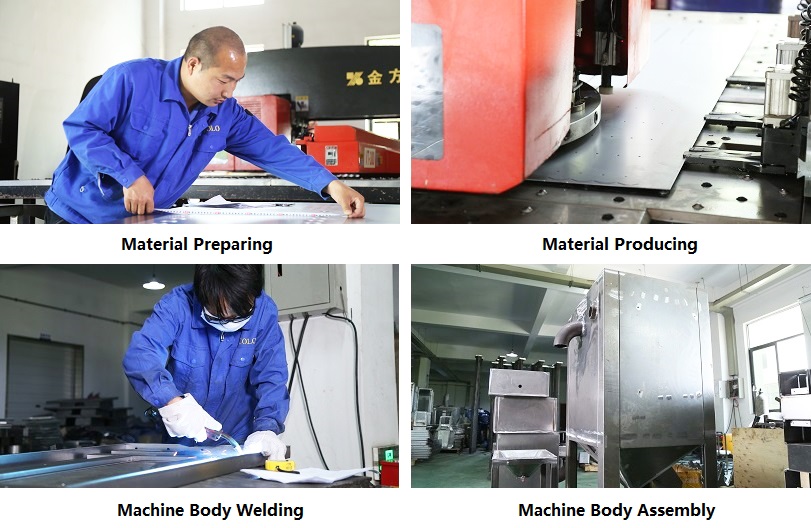

Located in Hangzhou, China, we we own a manufacturing base of 3600 square meter, around 100 employees and 24 sets production equipment, dividing into technical department, sales department, after-sale department, production department, QC department, manage and finance department, etc. As a fast growing company in supplying sandblasting equipment and mass finishing equipment, we devoted all ourselves to offering solution for any surface finishing problems.

All sand blasting machines were made in house by rich experienced production team of Kafan. To pursue best performance, each blast machine body is steel plate welded with powder coated surface, durable, wear-resistant and long lifespan, and the main components are famouse European brand imported, by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.

Our products can be divided into two main parts, sandblasting equipment and mass finishing machines.

Sandblasting equipment including: manual sandblasting machine, suction sand blast cabinet, pressure blasting machine, wet abrasive blasting equipment, portable blaster pot, automatic conveyor blast system, tumbler blaster, rotary table blast machine, crawl blast machine.

Mass finishing system including: vibratory polishing & deburring bowl, vibratory bowl with separator, centrifugal barrel tumbling machine, centrifugal disc finishing system, mass finishing media.

We offer service: Standard Production Models, Customized Design, Before-order Technical Support, Engineer Oversea Installing & Training, Free Sample Testing, 24 hour On-line Consulting, ODM, OEM.

Located in Hangzhou, China, we we own a manufacturing base of 3600 square meter, around 100 employees and 24 sets production equipment, dividing into technical department, sales department, after-sale department, production department, QC department, manage and finance department, etc. As a fast growing company in supplying sandblasting equipment and mass finishing equipment, we devoted all ourselves to offering solution for any surface finishing problems.

All sand blasting machines were made in house by rich experienced production team of Kafan. To pursue best performance, each blast machine body is steel plate welded with powder coated surface, durable, wear-resistant and long lifespan, and the main components are famouse European brand imported, by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.

Our products can be divided into two main parts, sandblasting equipment and mass finishing machines.

Sandblasting equipment including: manual sandblasting machine, suction sand blast cabinet, pressure blasting machine, wet abrasive blasting equipment, portable blaster pot, automatic conveyor blast system, tumbler blaster, rotary table blast machine, crawl blast machine.

Mass finishing system including: vibratory polishing & deburring bowl, vibratory bowl with separator, centrifugal barrel tumbling machine, centrifugal disc finishing system, mass finishing media.

We offer service: Standard Production Models, Customized Design, Before-order Technical Support, Engineer Oversea Installing & Training, Free Sample Testing, 24 hour On-line Consulting, ODM, OEM.