Kafan

| Availability: | |

|---|---|

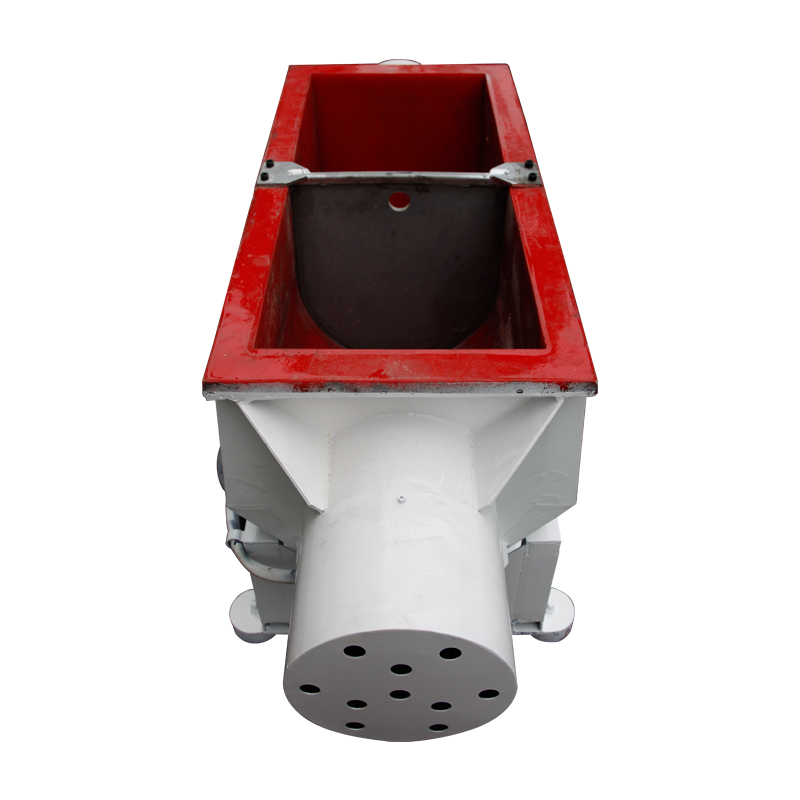

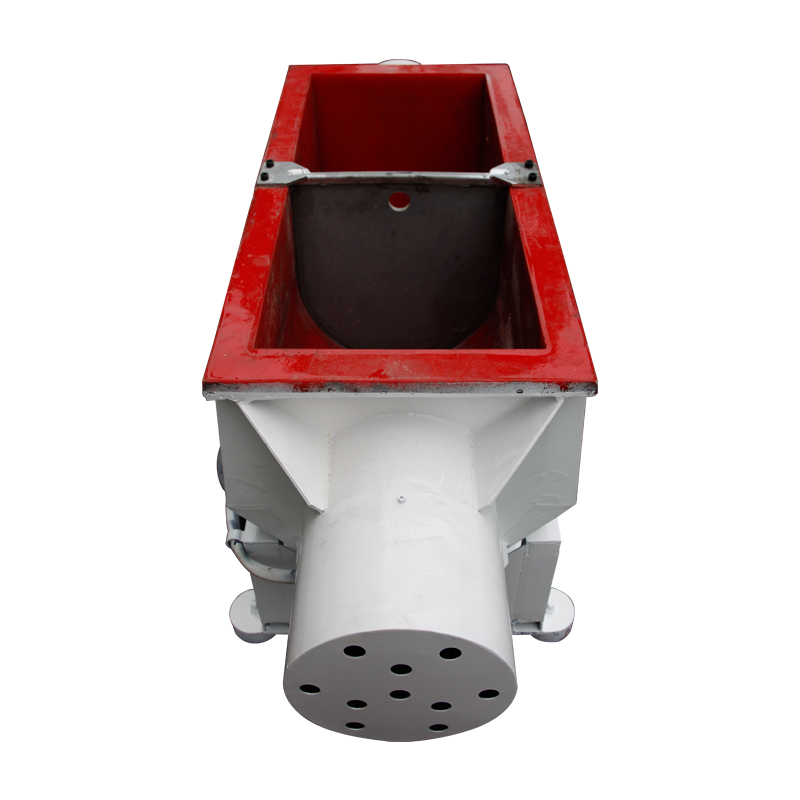

The vibratory finishing tube is applicable for deburring, removing rust, rounding and bright polishing for all kinds of parts made of metal, non-ferrous metal and non-metal in large qualities and in medium or large size.

Especially suitable for long-shaped parts finishing, or delicate components which are likely to damage part to part as the tube chamber can be sectioned with divider plates

After processed by vibratory tube, not only the original shape and position accuracy is maintained, but also the surface roughness of the part is reduced by 1 ~ 2 degree. After vibratory finishing, the surface microhardness of the part is improved,whose internal stress also can be eliminated to some extent the fatigue strength is improved.

1. The tube vibration polishing machine is mainly composed of a heavy-duty vibrating motor, a trough container, a base and springs uniformly arranged on the ase

2. With high wear-resistant polyurethane lined in the vibratory tube to increase the service life of more than 5 times as well as avoiding collisions on the wall and and reduce the noise.

3. The size of vibratory tube can be customized according to the requirements, the number of partitions in the tube can also be provided as request.

| Model | Capacity (L) | Line thickness (mm) | Net Weight (kg) | Motor Power (kw) | Inner Chamber Size(mm) | Outer Size (mm) |

| CL-200 | 200 | 20 | 500 | 2*1.1 | 1000X400X460 | 1600X440X750 |

| CL-500 | 500 | 22 | 1200 | 2*2.2 | 1170×690×680 | 2450×1000×955 |

| CL-700 | 700 | 22 | 1600 | 2*4.0 | 2200×730×645 | 3662×970×1080 |

| CL-1200 | 1200 | 22 | 2100 | 2*5.5 | 2000×750×854 | 3000×1050×1100 |

| CL-1800 | 1800 | 25 | 2800 | 2*5.5 | 2020×1120×940 | 3500×1336×1256 |

| CL-2800 | 2800 | 30 | 4000 | 2*9.0 | 1580×1510×1372 | 3500×1336×1256 |

The vibratory finishing tube is applicable for deburring, removing rust, rounding and bright polishing for all kinds of parts made of metal, non-ferrous metal and non-metal in large qualities and in medium or large size.

Especially suitable for long-shaped parts finishing, or delicate components which are likely to damage part to part as the tube chamber can be sectioned with divider plates

After processed by vibratory tube, not only the original shape and position accuracy is maintained, but also the surface roughness of the part is reduced by 1 ~ 2 degree. After vibratory finishing, the surface microhardness of the part is improved,whose internal stress also can be eliminated to some extent the fatigue strength is improved.

1. The tube vibration polishing machine is mainly composed of a heavy-duty vibrating motor, a trough container, a base and springs uniformly arranged on the ase

2. With high wear-resistant polyurethane lined in the vibratory tube to increase the service life of more than 5 times as well as avoiding collisions on the wall and and reduce the noise.

3. The size of vibratory tube can be customized according to the requirements, the number of partitions in the tube can also be provided as request.

| Model | Capacity (L) | Line thickness (mm) | Net Weight (kg) | Motor Power (kw) | Inner Chamber Size(mm) | Outer Size (mm) |

| CL-200 | 200 | 20 | 500 | 2*1.1 | 1000X400X460 | 1600X440X750 |

| CL-500 | 500 | 22 | 1200 | 2*2.2 | 1170×690×680 | 2450×1000×955 |

| CL-700 | 700 | 22 | 1600 | 2*4.0 | 2200×730×645 | 3662×970×1080 |

| CL-1200 | 1200 | 22 | 2100 | 2*5.5 | 2000×750×854 | 3000×1050×1100 |

| CL-1800 | 1800 | 25 | 2800 | 2*5.5 | 2020×1120×940 | 3500×1336×1256 |

| CL-2800 | 2800 | 30 | 4000 | 2*9.0 | 1580×1510×1372 | 3500×1336×1256 |

Tub finishers, or trough vibrators, are a versatile finishing machine for medium to large parts. For their capacity, tub finishers provide the maximum channel width and allow parts to be easily segregated with customizable, removable compartment divider

Scope of application:

1. For batch processing of complex surface of the small and medium-sized workpiece.

2. Remove the workpiece surface of the burr, oxide, oil, flash, rough throw, fine throw.

3. The process does not destroy the original size and shape of the part.

4. Easy to operate.

5. Suitable for copper, iron, aluminum, steel and other micro-metal parts

Tub finishers, or trough vibrators, are a versatile finishing machine for medium to large parts. For their capacity, tub finishers provide the maximum channel width and allow parts to be easily segregated with customizable, removable compartment divider

Scope of application:

1. For batch processing of complex surface of the small and medium-sized workpiece.

2. Remove the workpiece surface of the burr, oxide, oil, flash, rough throw, fine throw.

3. The process does not destroy the original size and shape of the part.

4. Easy to operate.

5. Suitable for copper, iron, aluminum, steel and other micro-metal parts

Optional features include:

PLC Controls.

Variable speed control.

Acoustic suppression covers.

Chemical additive dosing.

Effluent control.

Optional features include:

PLC Controls.

Variable speed control.

Acoustic suppression covers.

Chemical additive dosing.

Effluent control.

Tub Type Vibratory Finishing Machine

Tub Type Vibratory Finishing Machine