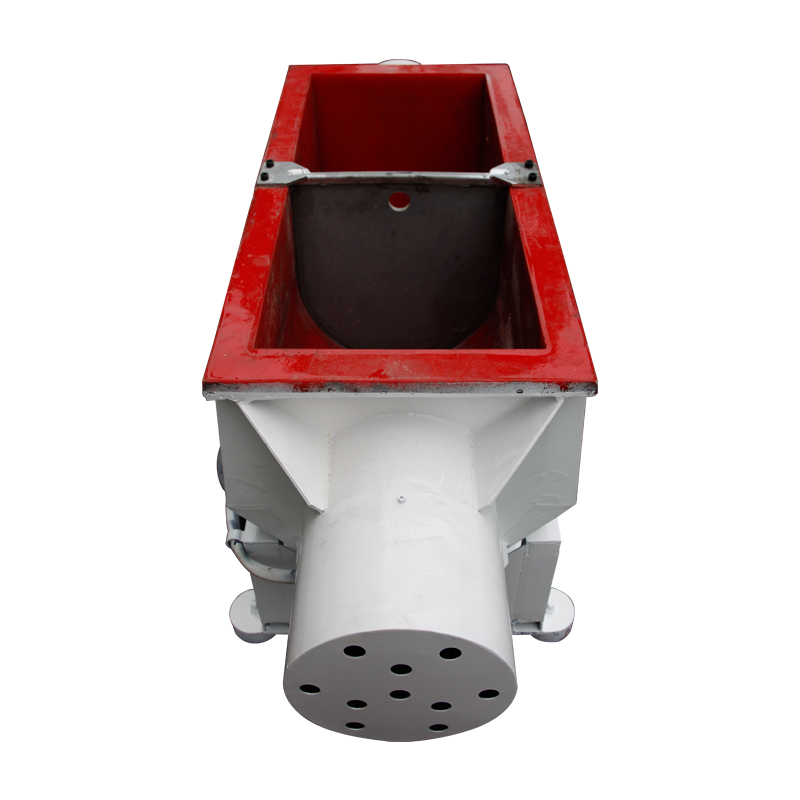

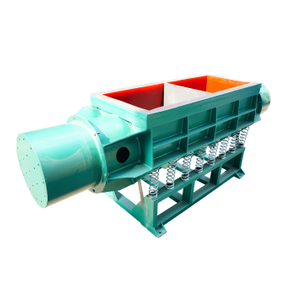

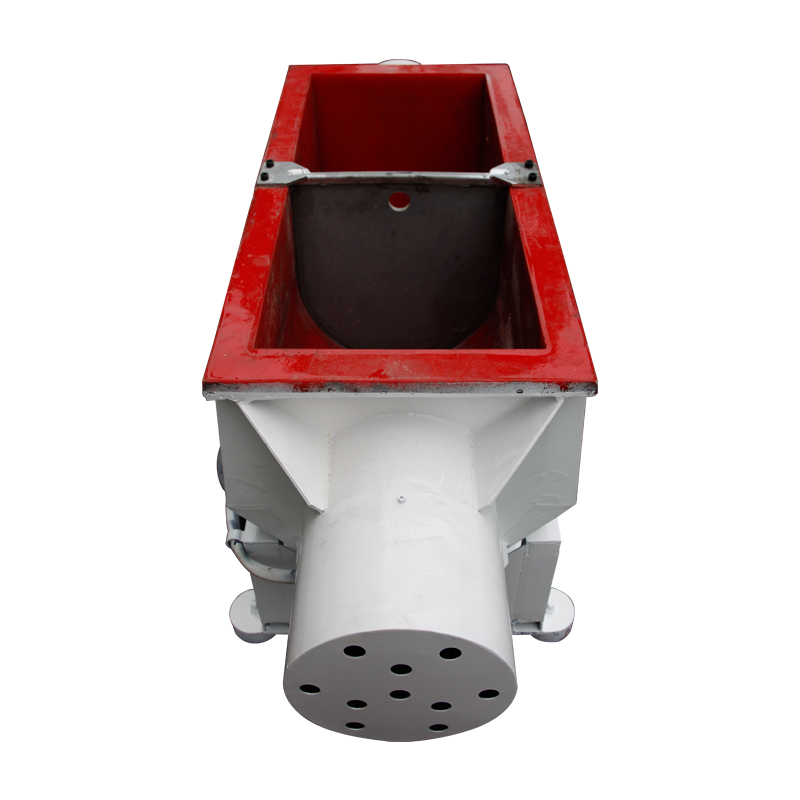

Vibratory Tub Finishing Machine with Divider Plate

Especially suitable for long-shaped parts or delicate components finishing which are likely to damage part to part as the tub chamber can be sectioned with divider plates.

Vibratory finishing is a technique to surface improve components made in various materials by combining the machines unique action, with associated finishing medias and compounds, processes can be descaling, cleaning, rounding, deflashing and polishing

Vibratory Tub Finishing Machine Standard Configurations

A trough container with high wear-resistant polyurethane lining

PU lining wall increase the service life of more than 5 times and reduce the noise.

A heavy-loaded base with springs uniformly arranged

Specially designed with high performance electric vibration motor

Tub sizes can be customized based on requirements

Available with custom quantities of divider devices

Vibratory Tub Finishing Machine Optional Configurations include:

VIbratory Tub Finishing Machine Specifications

| Model | Capacity (L) | Line thickness (mm) | Net Weight (kg) | Motor Power (kw) | Inner Chamber Size(mm) | Outer Size (mm) |

KF-200

| 200

| 20

| 500

| 2*1.1

| 1000X400X460 | 1600X440X750 |

| KF-500 | 500 | 22 | 1200 | 2*2.2 | 1170×690×680 | 2450×1000×955 |

| KF-700 | 700 | 22 | 1600 | 2*4.0 | 2200×730×645 | 3662×970×1080 |

| KF-1200 | 1200 | 22 | 2100 | 2*5.5 | 2000×750×854 | 3000×1050×1100 |

| KF-1800 | 1800 | 25 | 2800 | 2*5.5 | 2020×1120×940 | 3500×1336×1256 |

| KF-2800 | 2800 | 30 | 4000 | 2*9.0 | 1580×1510×1372 | 3500×1336×1256

|

How does tub vibratory finishing machine work?

After processed by vibratory tube, not only the original shape and position accuracy is maintained, but also the surface roughness of the part is reduced by 1 ~ 2 degree. After vibratory finishing, the surface microhardness of the part is improved,whose internal stress also can be eliminated to some extent the fatigue strength is improved.