KF-1080ZLW

Kafan

| Availability: | |

|---|---|

Wet tumble blaster installed with a rotary drum which holds large volume of small sized parts, is specially produced for batch finishing, deburring and surface preparation using liquid abrasive blasting technology. Our wet blast tumbler applies a PLC controller for precise, flexible, unmanned operation. This machine is a great option to free up time for customers and to help improve efficiency.

This automatic wet blasting system provides easy operation. Users just load workparts into the tumbling drum, close the door, set the blasting parameters on the PLC, and start the machine, all parts will be automatically finished entirely and evenly.

The tumble basket blast cabinet offers batch production by automatic tumbling & blasting, greatly saving manual labor and increase output. Wet blasting creates a finer and clean finish due to the lubrication and flushing action of the water during the blasting process.

Automatic Tumbling & Blasting

Configured with an automatic rotation drum, and 2 pcs automatic guns, 1 piece washing gun. This mechanism ensures full coverage of abrasive flow on parts' surfaces. The tumbling speed of drum with frequency control can meet different processing needs.

Automatic blasts guns can be also set for manual operation, each wet blast gun configures a high-flow 9.5mm boron carbide nozzle which is durable enough. Before order, quantity of auto blast guns can be customized according to different products and requirements.

PLC Control with Touching Interface

The machine operates using a PLC controller and touching interface. This controller is programmable with various functions needed to produce an optimal finish based on different quantities, size of products, also depends on the customer-requested effect.

The automatic blasting time, drum rotating speed, blast gun pressure, flushing time, pump working, etc, all parameters and functions can be set on the controller first, at then you can achieve a fully-automatic, unmannerd process.

Water Recirculating System (Optional)

You can add a water recirculating system that achieve a closed loop wet blasting system, which means it does not require running water,. A recirculating tank interconnected to the cabinet, the blasted slurry mixture will be transferred to the tank for separating of water and abrasive. which is filtered by precise filter paper and rinsing tank.

A skimmer is configured to remove floating oil or grease.

If in your workshop running water is not available there, or worrying about waste water disposal, a closed loop wet blast cabinet is a good choice.

| Model | KF-1010ZLW |

| Ouer Dimensions: | L1100*W1400*H1800mm |

| working cabinet size: | L1000*W1000*H800mm |

| Cabin Material: | Stainless Steel |

| Blasting gun: | 2pcs wet blasting gun |

| Blasting nozzle | 9.5mm diameter, boron carbide material |

| Voltage: | 380-415V 3phase 50HZ |

| Tumbling Drive Motor: | 1.5kw |

| Slurry Pump Motor: | 1.5kw |

| Fan Motor: | 0.75kw |

| Required air flow for each gun: | 0.5-1.1m3/min |

| Air pressure required: | 0.2-0.8Mbar |

| Volume of abrasive & water: | 50L |

| Suitable abrasive: | Glass beads(for aluminum, stainless steel), Brown aluminum oxide(for steel or other) 80#-320# |

| Feed abrasive: | 8-15kgs |

| Abrasive : Water (proortion) | 1:3 |

The tumble wet sandblaster is ideal for processing small accessories like screws, zipper head, electric components, metal and non-metal pieces, do the cleaning jobs with consistent quality results. Not only creates less fear of collision for sensitive parts, the blast machine also ensures all parts and surfaces are blasted by the tumbling action, even hard-to-reach corners and holes.

Wet tumble blaster installed with a rotary drum which holds large volume of small sized parts, is specially produced for batch finishing, deburring and surface preparation using liquid abrasive blasting technology. Our wet blast tumbler applies a PLC controller for precise, flexible, unmanned operation. This machine is a great option to free up time for customers and to help improve efficiency.

This automatic wet blasting system provides easy operation. Users just load workparts into the tumbling drum, close the door, set the blasting parameters on the PLC, and start the machine, all parts will be automatically finished entirely and evenly.

The tumble basket blast cabinet offers batch production by automatic tumbling & blasting, greatly saving manual labor and increase output. Wet blasting creates a finer and clean finish due to the lubrication and flushing action of the water during the blasting process.

Automatic Tumbling & Blasting

Configured with an automatic rotation drum, and 2 pcs automatic guns, 1 piece washing gun. This mechanism ensures full coverage of abrasive flow on parts' surfaces. The tumbling speed of drum with frequency control can meet different processing needs.

Automatic blasts guns can be also set for manual operation, each wet blast gun configures a high-flow 9.5mm boron carbide nozzle which is durable enough. Before order, quantity of auto blast guns can be customized according to different products and requirements.

PLC Control with Touching Interface

The machine operates using a PLC controller and touching interface. This controller is programmable with various functions needed to produce an optimal finish based on different quantities, size of products, also depends on the customer-requested effect.

The automatic blasting time, drum rotating speed, blast gun pressure, flushing time, pump working, etc, all parameters and functions can be set on the controller first, at then you can achieve a fully-automatic, unmannerd process.

Water Recirculating System (Optional)

You can add a water recirculating system that achieve a closed loop wet blasting system, which means it does not require running water,. A recirculating tank interconnected to the cabinet, the blasted slurry mixture will be transferred to the tank for separating of water and abrasive. which is filtered by precise filter paper and rinsing tank.

A skimmer is configured to remove floating oil or grease.

If in your workshop running water is not available there, or worrying about waste water disposal, a closed loop wet blast cabinet is a good choice.

| Model | KF-1010ZLW |

| Ouer Dimensions: | L1100*W1400*H1800mm |

| working cabinet size: | L1000*W1000*H800mm |

| Cabin Material: | Stainless Steel |

| Blasting gun: | 2pcs wet blasting gun |

| Blasting nozzle | 9.5mm diameter, boron carbide material |

| Voltage: | 380-415V 3phase 50HZ |

| Tumbling Drive Motor: | 1.5kw |

| Slurry Pump Motor: | 1.5kw |

| Fan Motor: | 0.75kw |

| Required air flow for each gun: | 0.5-1.1m3/min |

| Air pressure required: | 0.2-0.8Mbar |

| Volume of abrasive & water: | 50L |

| Suitable abrasive: | Glass beads(for aluminum, stainless steel), Brown aluminum oxide(for steel or other) 80#-320# |

| Feed abrasive: | 8-15kgs |

| Abrasive : Water (proortion) | 1:3 |

The tumble wet sandblaster is ideal for processing small accessories like screws, zipper head, electric components, metal and non-metal pieces, do the cleaning jobs with consistent quality results. Not only creates less fear of collision for sensitive parts, the blast machine also ensures all parts and surfaces are blasted by the tumbling action, even hard-to-reach corners and holes.

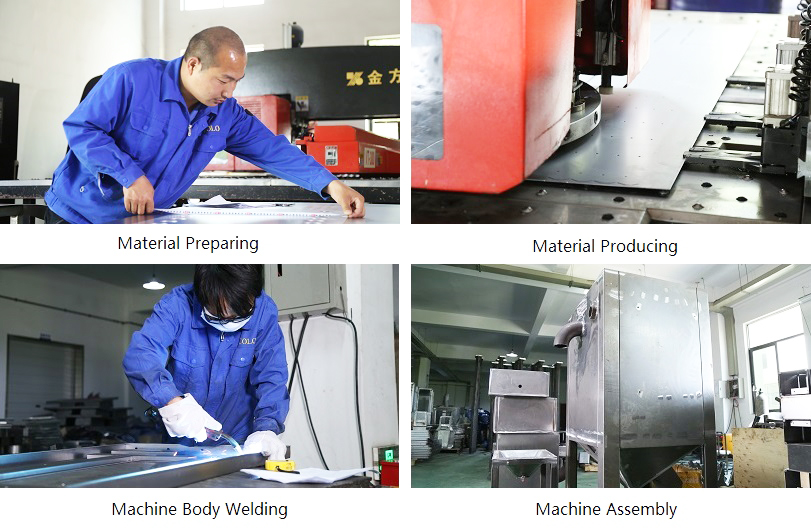

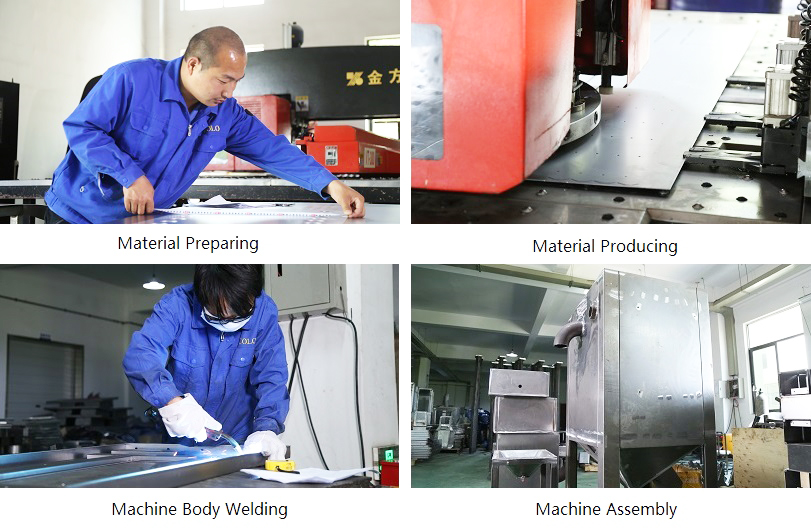

Devoted to world market for over 10 years, Kafan offer you factory-direct manufactured sand blasting machine in high quality and competitive price. With professional sales, techinical, production team, we provide blasting equipments in a variety of specifications and styles based on customers' requirements. Such as suction blast machine, pressure blast machine,portable blaster, wet blasting machine, automatic conveyor blast machine.

To pursue best performance, we use the latest technology for our blast components, our cabinets are fully welded with 2mm steel. Each component has proven reliability, we design and manufacture in-house. Each cabinet is fully equipped with high quality components that both have been designed and tested by us for optimal performance., by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.

Located in Hangzhou, China, we we own a manufacturing base of 3600 square meter, around 100 employees and 24 sets production equipment, dividing into technical department, sales department, after-sale department, production department, QC department, manage and finance department, etc. As a fast growing company in supplying sandblasting equipment and mass finishing equipment, we devoted all ourselves to offering solution for any surface finishing problems.

Our products can be divided into two main parts, sandblasting equipment and mass finishing machines.

Sandblasting equipment including: manual sandblasting machine, suction sand blast cabinet, pressure blasting machine, wet abrasive blasting equipment, portable blaster pot, automatic conveyor blast system, tumbler blaster, rotary table blast machine, crawl blast machine.

Mass finishing system including: vibratory polishing & deburring bowl, vibratory bowl with separator, centrifugal barrel tumbling machine, centrifugal disc finishing system, mass finishing media.

We offer service: Standard Production Models, Customized Design, Before-order Technical Support, Engineer Oversea Installing & Training, Free Sample Testing, 24 hour On-line Consulting, ODM, OEM.

Devoted to world market for over 10 years, Kafan offer you factory-direct manufactured sand blasting machine in high quality and competitive price. With professional sales, techinical, production team, we provide blasting equipments in a variety of specifications and styles based on customers' requirements. Such as suction blast machine, pressure blast machine,portable blaster, wet blasting machine, automatic conveyor blast machine.

To pursue best performance, we use the latest technology for our blast components, our cabinets are fully welded with 2mm steel. Each component has proven reliability, we design and manufacture in-house. Each cabinet is fully equipped with high quality components that both have been designed and tested by us for optimal performance., by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.

Located in Hangzhou, China, we we own a manufacturing base of 3600 square meter, around 100 employees and 24 sets production equipment, dividing into technical department, sales department, after-sale department, production department, QC department, manage and finance department, etc. As a fast growing company in supplying sandblasting equipment and mass finishing equipment, we devoted all ourselves to offering solution for any surface finishing problems.

Our products can be divided into two main parts, sandblasting equipment and mass finishing machines.

Sandblasting equipment including: manual sandblasting machine, suction sand blast cabinet, pressure blasting machine, wet abrasive blasting equipment, portable blaster pot, automatic conveyor blast system, tumbler blaster, rotary table blast machine, crawl blast machine.

Mass finishing system including: vibratory polishing & deburring bowl, vibratory bowl with separator, centrifugal barrel tumbling machine, centrifugal disc finishing system, mass finishing media.

We offer service: Standard Production Models, Customized Design, Before-order Technical Support, Engineer Oversea Installing & Training, Free Sample Testing, 24 hour On-line Consulting, ODM, OEM.