KFW-30

Kafan

Centrifugal Barrel Finishing Machine

| Availability: | |

|---|---|

The centrifugal barrel finishing machine offers “High Energy” precision deburring and polishing with a wide range of speeds, centrifugal tumbling action provides a quick removal of heavy burrs, sharp edges or thick contaminants, which creates safe and shiny surfaces of various industry parts. The strong centrifugal cutting force tends to do those tough jobs while vibratory finishing can not achieve, with improved efficiency 10-20 times. Easy-operated centrifugal barrel tumbling machine is applicable to proces batch small or medium sized parts.

There are several barrels in the inner cavity of the centrifugal polishing machine, which can handle different workpieces at the same time to avoid collision.

2, Choose polyurethane as the lining material of the tumbler barrel, high wear-resistance, acid and alkali resistance, long service life, easy replacement.

3. The upper part of the machine is provided with an arc cover, which is a movable sliding door, the machine start only when the sliding door is closed, it is safe and reliable.

4. The centrifugal barrel finisher if over 60L capacity will be installed with electric discharging mechanism, which reduces the labor and simplifies the process.

5, May match the frequency converter, aims to the precisely adjusting rotational speed, supports different products and demands, optimize finishing effect.

6, Optional time controller, accurate control of grinding time to ensure the stability of the polishing effect

| Model | Capacity | Motor Power | Speed | Inner Lining | Weight | Size(L*W*H) |

| KFW-15 | 2*7.5L | 1.1kw | 185r/min | 5-8mm | 200kg | 850*880*980mm |

| KFW-30 | 4*7.5L | 1.5kw | 185r/min | 5-8mm | 350kg | 970*990*1175mm |

| KFW-40 | 4*10L | 2.2kw | 165r/min | 6-10mm | 800kg | 1100*1000*1400mm |

| KFW-60 | 4*15L | 5.5kw | 165r/min | 8-12mm | 1000kg | 1150*1100*1700 |

| KFW-80 | 4*20L | 5.5kw | 145r/min | 8-12mm | 1200kg | 1300*1250*1815mm |

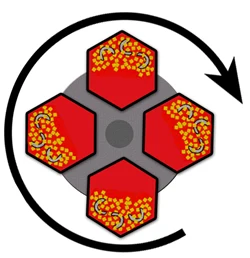

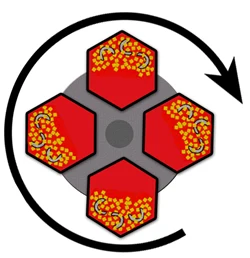

Each centrifugal barrel tumbling machine contains four barrels that are mounted to a drum. The operator fills the barrel with media, parts and water, roughly 50-90% full. During operation the entire drum of the debur tool rotates like a Ferris wheel. As the speed increases, the media and parts rub against one another randomly and repeatedly, removing even the smallest imperfections. In a matter of minutes the finishing cycle is complete and the parts are ready to be separated from the media

Applicable for batch deburring, chamfering, descaling, polishing of metal and non-metal parts, etc. Such as apparel accessories, glasses accessories, watch and clock accessories, electronic accessories, hardware, machiney accessories in different shapes and hardness.

The centrifugal barrel finishing machine offers “High Energy” precision deburring and polishing with a wide range of speeds, centrifugal tumbling action provides a quick removal of heavy burrs, sharp edges or thick contaminants, which creates safe and shiny surfaces of various industry parts. The strong centrifugal cutting force tends to do those tough jobs while vibratory finishing can not achieve, with improved efficiency 10-20 times. Easy-operated centrifugal barrel tumbling machine is applicable to proces batch small or medium sized parts.

There are several barrels in the inner cavity of the centrifugal polishing machine, which can handle different workpieces at the same time to avoid collision.

2, Choose polyurethane as the lining material of the tumbler barrel, high wear-resistance, acid and alkali resistance, long service life, easy replacement.

3. The upper part of the machine is provided with an arc cover, which is a movable sliding door, the machine start only when the sliding door is closed, it is safe and reliable.

4. The centrifugal barrel finisher if over 60L capacity will be installed with electric discharging mechanism, which reduces the labor and simplifies the process.

5, May match the frequency converter, aims to the precisely adjusting rotational speed, supports different products and demands, optimize finishing effect.

6, Optional time controller, accurate control of grinding time to ensure the stability of the polishing effect

| Model | Capacity | Motor Power | Speed | Inner Lining | Weight | Size(L*W*H) |

| KFW-15 | 2*7.5L | 1.1kw | 185r/min | 5-8mm | 200kg | 850*880*980mm |

| KFW-30 | 4*7.5L | 1.5kw | 185r/min | 5-8mm | 350kg | 970*990*1175mm |

| KFW-40 | 4*10L | 2.2kw | 165r/min | 6-10mm | 800kg | 1100*1000*1400mm |

| KFW-60 | 4*15L | 5.5kw | 165r/min | 8-12mm | 1000kg | 1150*1100*1700 |

| KFW-80 | 4*20L | 5.5kw | 145r/min | 8-12mm | 1200kg | 1300*1250*1815mm |

Each centrifugal barrel tumbling machine contains four barrels that are mounted to a drum. The operator fills the barrel with media, parts and water, roughly 50-90% full. During operation the entire drum of the debur tool rotates like a Ferris wheel. As the speed increases, the media and parts rub against one another randomly and repeatedly, removing even the smallest imperfections. In a matter of minutes the finishing cycle is complete and the parts are ready to be separated from the media

Applicable for batch deburring, chamfering, descaling, polishing of metal and non-metal parts, etc. Such as apparel accessories, glasses accessories, watch and clock accessories, electronic accessories, hardware, machiney accessories in different shapes and hardness.