KFW-30

Kafan

Centrifugal Barrel Finishing Machine

| Availability: | |

|---|---|

The centrifugal barrel finishing machine is perfect for small parts that require quick processes, powerfully handling all of your finishing and polishing needs. Centrifugal finisher provides consistent, repeatable finishing, whose working cycle is up to 30 times faster over vibratory and rotary finishing.

Several individual barrels allow for different parts to be processed at the same time, offering versatility and efficiency.

Driven by belt/chain, makes smooth and stable movement with low nossise, less maintenance.

The barrel lining is long life polyurethanes, minimize the impact damage during working. wear & corrosion resistant,

Barrels are locked with a simple lid and cam system allows quick loading, as well as ensuring workparts safe.

The upper part of the machine is installed with an arc cover, which is a movable sliding door, the machine starting only when the sliding door is closed, it is safe and reliable.

| Model | Capacity | Motor Power | Speed | Inner Lining | Weight | Size(L*W*H) |

| KFW-15 | 2*7.5L | 1.1kw | 185r/min | 5-8mm | 200kg | 850*880*980mm |

| KFW-30 | 4*7.5L | 1.5kw | 185r/min | 5-8mm | 350kg | 970*990*1175mm |

| KFW-40 | 4*10L | 2.2kw | 165r/min | 6-10mm | 800kg | 1100*1000*1400mm |

| KFW-60 | 4*15L | 5.5kw | 165r/min | 8-12mm | 1000kg | 1150*1100*1700 |

| KFW-80 | 4*20L | 5.5kw | 145r/min | 8-12mm | 1200kg | 1300*1250*1815mm |

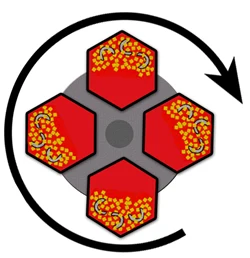

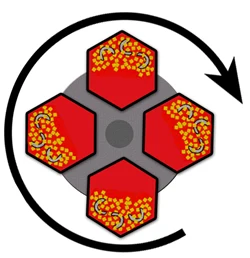

Each centrifugal finishing machine contains four barrels that are mounted to a drum. The operator fills the barrel with media, parts and water, roughly 50-90% full. During operation the entire drum of the debur tool rotates like a Ferris wheel. As the speed increases, the media and parts rub against one another randomly and repeatedly, removing even the smallest imperfections. In a matter of minutes the finishing cycle is complete and the parts are ready to be separated from the media

Applicable for batch deburring, chamfering, descaling, polishing of metal and non-metal parts, etc. Such as apparel accessories, glasses accessories, watch and clock accessories, electronic accessories, hardware, machiney accessories in different shapes and hardness. It is especially a kind of ideal finishing equipment for the complicated and irregular parts.

The centrifugal barrel finishing machine is perfect for small parts that require quick processes, powerfully handling all of your finishing and polishing needs. Centrifugal finisher provides consistent, repeatable finishing, whose working cycle is up to 30 times faster over vibratory and rotary finishing.

Several individual barrels allow for different parts to be processed at the same time, offering versatility and efficiency.

Driven by belt/chain, makes smooth and stable movement with low nossise, less maintenance.

The barrel lining is long life polyurethanes, minimize the impact damage during working. wear & corrosion resistant,

Barrels are locked with a simple lid and cam system allows quick loading, as well as ensuring workparts safe.

The upper part of the machine is installed with an arc cover, which is a movable sliding door, the machine starting only when the sliding door is closed, it is safe and reliable.

| Model | Capacity | Motor Power | Speed | Inner Lining | Weight | Size(L*W*H) |

| KFW-15 | 2*7.5L | 1.1kw | 185r/min | 5-8mm | 200kg | 850*880*980mm |

| KFW-30 | 4*7.5L | 1.5kw | 185r/min | 5-8mm | 350kg | 970*990*1175mm |

| KFW-40 | 4*10L | 2.2kw | 165r/min | 6-10mm | 800kg | 1100*1000*1400mm |

| KFW-60 | 4*15L | 5.5kw | 165r/min | 8-12mm | 1000kg | 1150*1100*1700 |

| KFW-80 | 4*20L | 5.5kw | 145r/min | 8-12mm | 1200kg | 1300*1250*1815mm |

Each centrifugal finishing machine contains four barrels that are mounted to a drum. The operator fills the barrel with media, parts and water, roughly 50-90% full. During operation the entire drum of the debur tool rotates like a Ferris wheel. As the speed increases, the media and parts rub against one another randomly and repeatedly, removing even the smallest imperfections. In a matter of minutes the finishing cycle is complete and the parts are ready to be separated from the media

Applicable for batch deburring, chamfering, descaling, polishing of metal and non-metal parts, etc. Such as apparel accessories, glasses accessories, watch and clock accessories, electronic accessories, hardware, machiney accessories in different shapes and hardness. It is especially a kind of ideal finishing equipment for the complicated and irregular parts.