Automatic Alloy Wheel Shot Blaster Cabinet

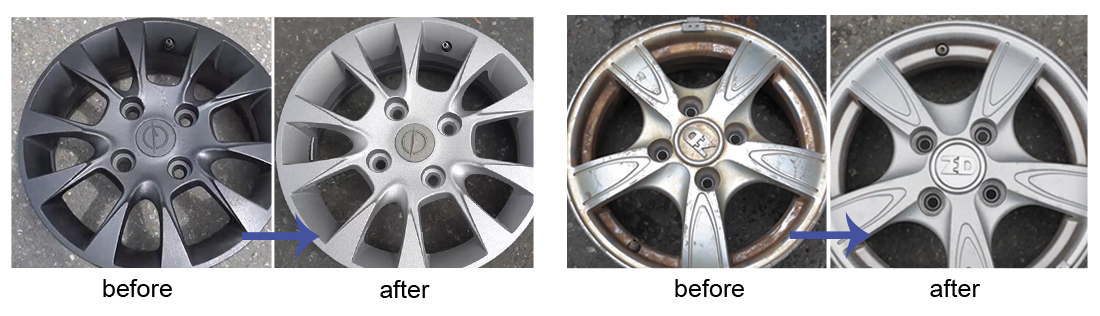

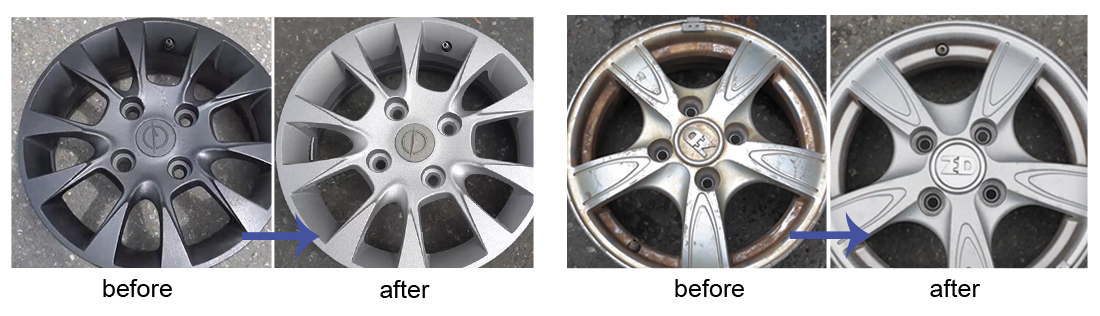

The automatic shot blaster cabinet is special designed for wheel or rim processing. It allows blasting one piece wheel each time with fully automatic process, extremetly efficient for rust-removing or paint removing. What's more, shot blasting machine gives an alloy wheel rim surface a roughness for good adhesion that will get perfect powder coat applications.

How does automatic wheel shot blaster work?

Wheel shot blaster is powered by electromechanical not by compressed air, it works through a high-speed rotating impeller to throw out steel shots in high speed and high flow, thus creates more forceful impact to surface. The turbines located at appropriate angles blasts steel shots and cleans part surfaces.

The alloy wheel is placed in the chamber where the process is fully automatic and can be controlled by a timer. Each finishing circle allows one piece alloy wheel blasted but only takes 3-5 minutes.

Automatic Wheel Shot Blast Cabinet Components

Shot Blasting Chamber

The specially designed shot blasting chamber for holding alloy wheel consists of protetive bracket, and 2 rollers for continuous wheel rolling, ensures thorough cleaning and cleaning.

Roller Drive Power:400w

Impeller head: 1set

The head is designed for complete shot blasting of the wheel to be cleaned, and minimize the empty throw of the steel shot on the basis of covering all the wheels to be cleaned.

Impeller head drive power: 7.5KW (Frequency adjustable)

Elevator: 1set

The elevator works through a belt. There is a hopper fixed on the conveyor belt scraping the wasted blasting shots at the bottom, then feeds the shots to the top driven by the elevator motor. Finally under the centrifugal gravity the shots drops to the separator. There is an access door on the elevator cover for easy maintenance and replacing wearing parts.

Elevator Power: 1.5kw

Filter Dust Collector: 1 Set

It uses new advanced filter material. The dust can not penetrate into the interior of the filter material, it has the characteristics of low resistance and easy cleaning, and its filtration precision reaches 5μm. Dust removal efficiency is up to 99.5%.

Fan motor power:2.2KW, Air flow:6800m3/h

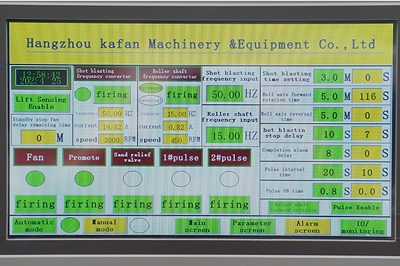

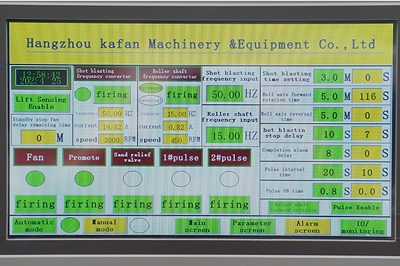

PLC Electric Control: 1Set

PLC control with touching screen offers high precision and user-friendly operation, ans is convenient for debugging.

The operator can start each functional component in sequence, or jog the individual functional components out of order to test the performance and operation status.

Automatic Alloy Wheel Shot Blaster Cabinet Specifications

| Working Chamber Size | L1200*W1200*H120mm |

| Suitable wheel size: | Diameter700mm * Thickness500mm (Or smaller) |

| Control System | PLC |

| Rotating Speed of Rollers: | Adjustable |

Shot Blasting Speed

| Adjustable |

| Dust Collector Type: | Anti-flame filters |

Power Supply:

| Electric |

Impeller head power: | 7.5KW |

| Fan motor power: | 2.2KW |

| Roller Drive Power | 400W |

| Elevator system power: | 1.5KW |

Automatic Alloy Wheel Shot Blaster Applications

The alloy wheel shot blaster is the initial choice for wheel surface finishing, especially for stripping old paints or removing corrosion, rust, scale, you'll fastly get a original alloy wheel but with a certain roughness, a necessary preparing for subsequent painting or powder coating process,

FAQ on Automatic Wheel Shot Blaster

1.Does it shot blast 1 piece of wheel at a time?

Yeah, it processes one wheel each time and cover all the surface. The wheel doesn't need to be turned over.

If you would like to do more wheels each time. Bigger size wheel shot blasting machine can be made.

2. How long does it take to shot blast 1 wheel?

It takes about 1-3 minutes to finish shot blasting one wheel. Its efficiency is relatively high.

3. What is the power source of the wheel shot blaster?

It's airless and powered by electricity, thus doesn't need to work with air compressor.

After connecting with electric power source, it begins to work, whose total power is about 13KW.

4.How long does the dust collector need to be replaced?

It depends. As usual, 6-9months around.