Direct Pressure Sand Blast Cabinet

Direct pressure blast cabinet is ideal for tough jobs, such as operating hard stuff, stripping thick unqualified layers which requires stronger cutting force, and applied to where large-scale surface must be cleaned quickly, as well as

blast cleaning jobs that needs the use of heavy media or large mesh sizes, such as steel ball.

Direct Pressure Blast Cabinet Configurations

1. Well-sealed enclosed cabinet design with transparent glass view window, environment-friendly and user-friendly.

2. Pressure pot adopts newly-developed exhaust valve device to avoid the machine faults and require less maintenance

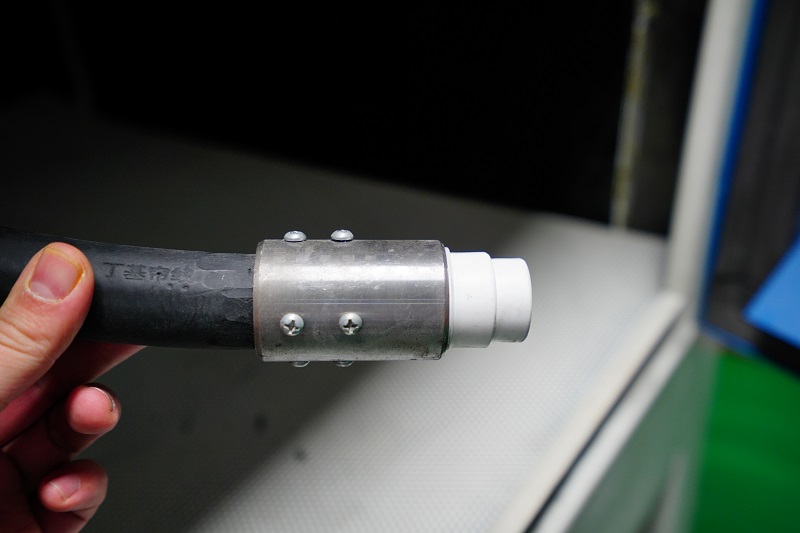

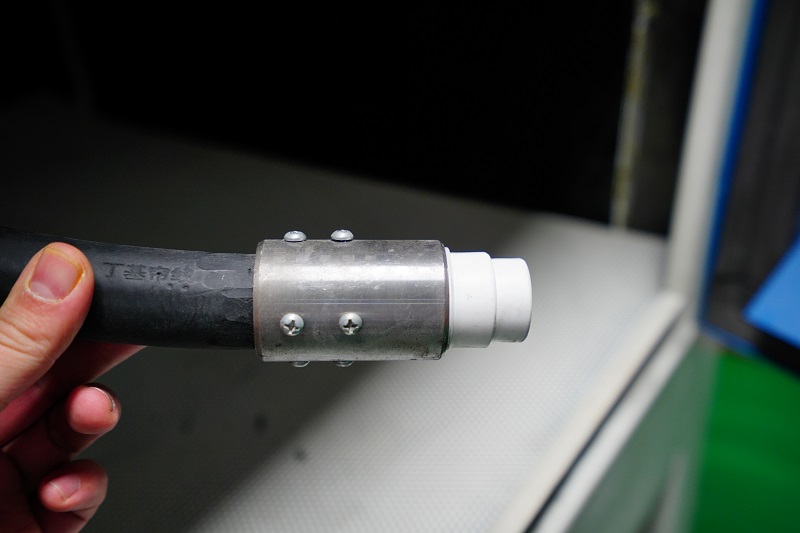

3. High pressure sandblasting gun reaches high working efficiency and intensity, equipped with boron carbide nozzle that is durable enough for long service life.

4. Foot swicth makes it flexible to control the working of blast gun, safe and reliability.

5. Cartridge filter unit that collects dust ensures the air discharged to the atmosphere is free of particles. cyclone device that effective separates fine abrasives from dust for recycling.

6. Can be specially designed with a turntable to loads heavy workparts(such as alloy wheels), allows users to operate easily by rotating the table.

Blast Nozzle

Foot Switch

Pressure Pot

Blast Cabinet

Heavy-duty Turntable

KF-1010PC Direct Pressure Cabinet Cabinet Specifications

| Model | KF-1010PC |

| Outer Size | length1450*Width1000*Height2050mm |

| Working Cabinet Size | length1000*Width1000*Height800mm |

| Loading Capacity | 80-100kg |

| Dust Removal | Cartridge filter dust collector |

| Lighting | LED 18W lamp, 1 pc |

| Spray Gun | high-pressure spray gun, 1pc |

| Shell | 2mm cold-rolled welded steel plate |

| Pressure Gauge | 2 pcs |

| Regulator | 1 pc |

| Dust Valve | 1 pc |

Hot Sale Standard Models of Diect Pressure Blast Cabinet

| Model | Working Cabinet Size | Loading Capacity |

| KF-9080PC | L900*W800*H800mm | 80-100kgs |

| KF-1010PC | L1000*W1000*H800mm | 80-100kgs |

| KF-1212PC | L1200*W1200*H800mm | 100-120kgs

|

Why choose Kafan sand blast cabinet?

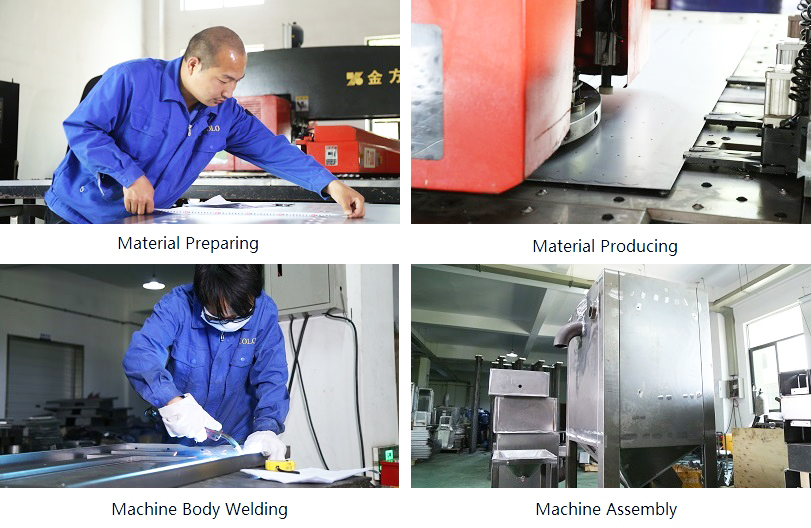

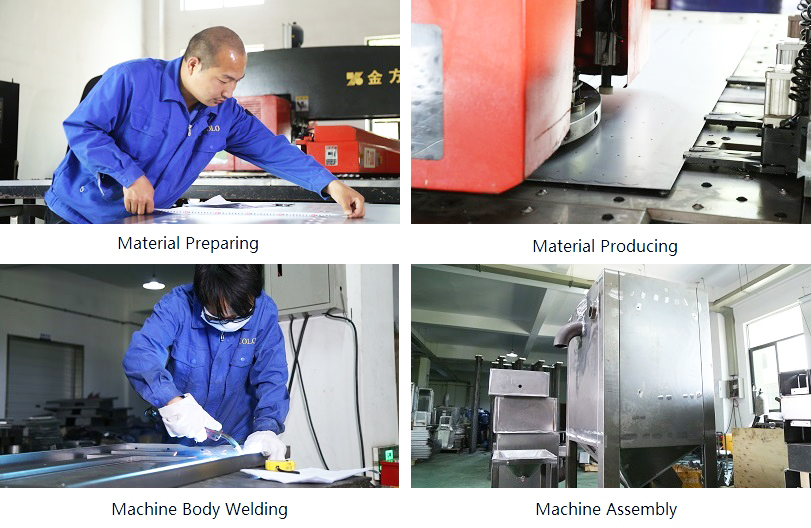

Devoted to world market for over 10 years, Kafan offer you factory-direct manufactured sand blasting machine in high quality and competitive price. With professional sales, techinical, production team, we provide blasting equipments in a variety of specifications and styles based on customers' requirements. Such as suction blast machine, pressure blast machine,portable blaster, wet blasting machine, automatic conveyor blast machine.

To pursue best performance, we use the latest technology for our blast components, our cabinets are fully welded with 2mm steel. Each component has proven reliability, we design and manufacture in-house. Each cabinet is fully equipped with high quality components that both have been designed and tested by us for optimal performance., by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.