KF-1212

Kafan

| Availability: | |

|---|---|

- In the manual suction sandblasting cabinet, users handle the workparts through a manual blast gun controlled via foot switch.

- Each of our sandblasting cabinets are designed with a dust collecting system which configured with cartridge filter, fan motor, effectively removing dust away from the operator's window for increased visibility and accuracy when cleaning.

- It is optional to add a cyclone device used to separate ultrafine abrasives from dusts.

Enclosed Cabinet Well-sealed enclosed cabinet designe is environmetal-friendly |  Blasting Gloves Durable blasting gloves for long time use. |  Lights Built with energy-saving lights provides a clearer visibility. |

Sand Blasting Guns Alloy body holder complete with durable boron carbide nozzle |  Air Blowing Gun Using after blasting process - removal of surplus dust and blasting media. |  Foot Pedal Switch control the work of blasting gun, which reduces the user’s fatigue, |

| Model: | KF-1212 |

| Overall Dimension: | Length1620 * Width1300 * Height1800mm |

| Working Dimension: | Length1200 * Width1200 * Height800mm |

| Loading Capacity | Max.500kgs (as request) |

| Power Supply: | 110V/220V, 50-60Hz, customized |

| Lighting: | 18w Fluorescent |

| Fan Motor Power: | 0.75kw |

| Compressed Air Pressure: | Dry and clean compressed air, 3-8 bar(kg/cm^2) |

| Required Air Flow: | 0.5-1.2m^3/min |

| Model | Outer Dimension(L*W*Hmm) | Working Dimension(L*W*Hmm) |

| KF-6050 | 830*600*1500 | 600*500*650 |

| KF-7050 | 930*700*1500 | 700*500*650 |

| KF-9060 | 1030*900*1650 | 900*600*650 |

| KF-9080 | 1230*900*1700 | 900*800*800 |

| KF-1010 | 1430*1100*1800 | 1000*1000*800 |

| KF-1212 | 1620*1300*1800 | 1200*1200*800 |

Suction blast cabinet, also called siphon blaster, use negative pressure created by the blasting gun to suck and deliver the compressed air and abrasive to the nozzle then blasting on the workpiece surface.

This indirect pressure though not powerful as the direct pressure sandblaster, it is the initial economical choice of most sandblasting applications. The blasted abrasives will impact and grind with the surface, in which way remove the impurities, rust, oxide layer and other contaminants, results in a smooth and clean surface for subsequent procedure.

1. More environmental-friendly than chemical cleaning and cleans more thoroughly than dry ice blasting.

2. Cause no pollution on the workpieces surface and no chemical reaction between workpieces and blasting media

3. Corners or other awkward places can be easily reached and cleaned by sandblasting machine.

4. Processing by sandblasting cabinet can greatly improve the surface cleaning and reduce much manual effort.

5. One machine can obtain various surface treatments, such as removing rust and scales, stripping old coats, matt-finishing, carving, etc

- In the manual suction sandblasting cabinet, users handle the workparts through a manual blast gun controlled via foot switch.

- Each of our sandblasting cabinets are designed with a dust collecting system which configured with cartridge filter, fan motor, effectively removing dust away from the operator's window for increased visibility and accuracy when cleaning.

- It is optional to add a cyclone device used to separate ultrafine abrasives from dusts.

Enclosed Cabinet Well-sealed enclosed cabinet designe is environmetal-friendly |  Blasting Gloves Durable blasting gloves for long time use. |  Lights Built with energy-saving lights provides a clearer visibility. |

Sand Blasting Guns Alloy body holder complete with durable boron carbide nozzle |  Air Blowing Gun Using after blasting process - removal of surplus dust and blasting media. |  Foot Pedal Switch control the work of blasting gun, which reduces the user’s fatigue, |

| Model: | KF-1212 |

| Overall Dimension: | Length1620 * Width1300 * Height1800mm |

| Working Dimension: | Length1200 * Width1200 * Height800mm |

| Loading Capacity | Max.500kgs (as request) |

| Power Supply: | 110V/220V, 50-60Hz, customized |

| Lighting: | 18w Fluorescent |

| Fan Motor Power: | 0.75kw |

| Compressed Air Pressure: | Dry and clean compressed air, 3-8 bar(kg/cm^2) |

| Required Air Flow: | 0.5-1.2m^3/min |

| Model | Outer Dimension(L*W*Hmm) | Working Dimension(L*W*Hmm) |

| KF-6050 | 830*600*1500 | 600*500*650 |

| KF-7050 | 930*700*1500 | 700*500*650 |

| KF-9060 | 1030*900*1650 | 900*600*650 |

| KF-9080 | 1230*900*1700 | 900*800*800 |

| KF-1010 | 1430*1100*1800 | 1000*1000*800 |

| KF-1212 | 1620*1300*1800 | 1200*1200*800 |

Suction blast cabinet, also called siphon blaster, use negative pressure created by the blasting gun to suck and deliver the compressed air and abrasive to the nozzle then blasting on the workpiece surface.

This indirect pressure though not powerful as the direct pressure sandblaster, it is the initial economical choice of most sandblasting applications. The blasted abrasives will impact and grind with the surface, in which way remove the impurities, rust, oxide layer and other contaminants, results in a smooth and clean surface for subsequent procedure.

1. More environmental-friendly than chemical cleaning and cleans more thoroughly than dry ice blasting.

2. Cause no pollution on the workpieces surface and no chemical reaction between workpieces and blasting media

3. Corners or other awkward places can be easily reached and cleaned by sandblasting machine.

4. Processing by sandblasting cabinet can greatly improve the surface cleaning and reduce much manual effort.

5. One machine can obtain various surface treatments, such as removing rust and scales, stripping old coats, matt-finishing, carving, etc

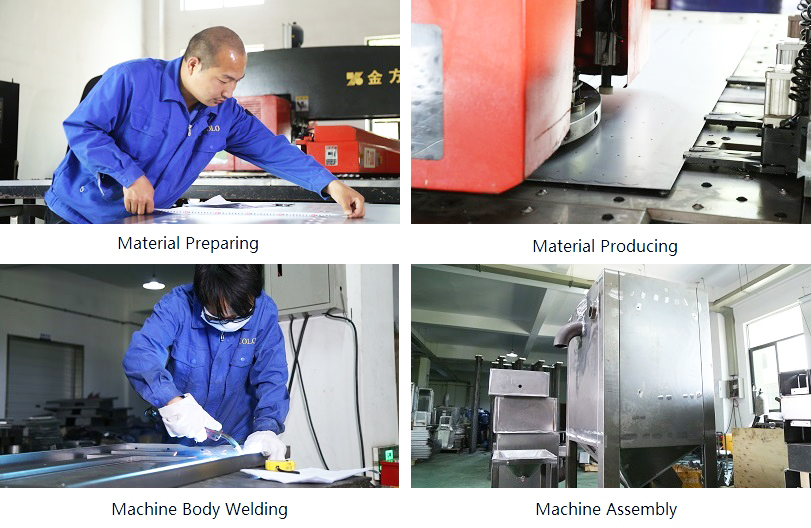

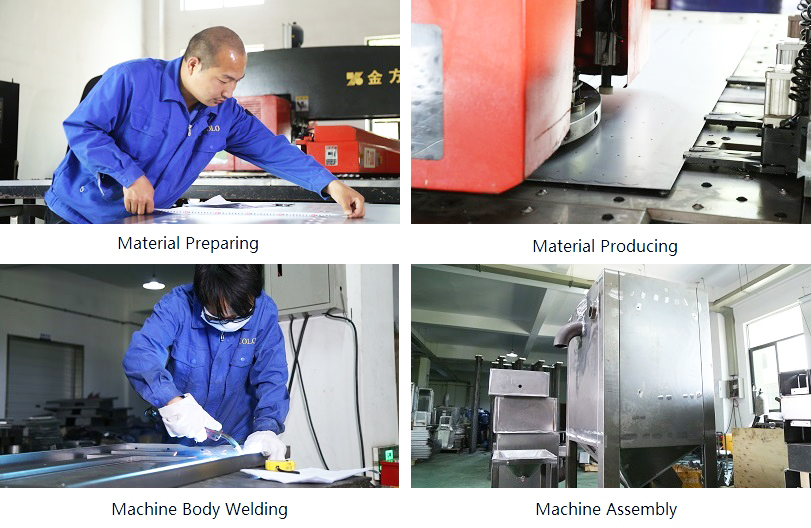

Located in Hangzhou, China, we we own a manufacturing base of 3600 square meter, around 100 employees and 24 sets production equipment, dividing into technical department, sales department, after-sale department, production department, QC department, manage and finance department, etc. As a fast growing company in supplying sandblasting equipment and mass finishing equipment, we devoted all ourselves to offering solution for any surface finishing problems.

Our products can be divided into two main parts, sandblasting equipment and mass finishing machines.

Sandblasting equipment including: manual sandblasting machine, suction sand blast cabinet, pressure blasting machine, wet abrasive blasting equipment, portable blaster pot, automatic conveyor blast system, tumbler blaster, rotary table blast machine, crawl blast machine.

Mass finishing system including: vibratory polishing & deburring bowl, vibratory bowl with separator, centrifugal barrel tumbling machine, centrifugal disc finishing system, mass finishing media.

We offer service: Standard Production Models, Customized Design, Before-order Technical Support, Engineer Oversea Installing & Training, Free Sample Testing, 24 hour On-line Consulting, ODM, OEM.

Kafan - Professional Manufacturer of Sandblasting Equipment

All sandblasting machines are made in house by rich experienced production team of Kafan, we can directly control the cost and quality. To pursue best performance, each machine body is steel plate welded with powder coated surface, durable, wear-resistant and long lifespan, and the main components are imported, by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.

Located in Hangzhou, China, we we own a manufacturing base of 3600 square meter, around 100 employees and 24 sets production equipment, dividing into technical department, sales department, after-sale department, production department, QC department, manage and finance department, etc. As a fast growing company in supplying sandblasting equipment and mass finishing equipment, we devoted all ourselves to offering solution for any surface finishing problems.

Our products can be divided into two main parts, sandblasting equipment and mass finishing machines.

Sandblasting equipment including: manual sandblasting machine, suction sand blast cabinet, pressure blasting machine, wet abrasive blasting equipment, portable blaster pot, automatic conveyor blast system, tumbler blaster, rotary table blast machine, crawl blast machine.

Mass finishing system including: vibratory polishing & deburring bowl, vibratory bowl with separator, centrifugal barrel tumbling machine, centrifugal disc finishing system, mass finishing media.

We offer service: Standard Production Models, Customized Design, Before-order Technical Support, Engineer Oversea Installing & Training, Free Sample Testing, 24 hour On-line Consulting, ODM, OEM.

Kafan - Professional Manufacturer of Sandblasting Equipment

All sandblasting machines are made in house by rich experienced production team of Kafan, we can directly control the cost and quality. To pursue best performance, each machine body is steel plate welded with powder coated surface, durable, wear-resistant and long lifespan, and the main components are imported, by all of which we ensure 1 year warranty period for any quality problem. For sea shipping, we will strictly packed in film and foam first, with wooden case outside to make sure it is safe and intact to your country.