Alloy Wheel Refurbishment Equipment, Blast Cleaning & Powder Coating

Wheel refurbishment process is used to restore alloy wheels back to their original condition or customize them to any colour or finish. We recommend blasting and powder coating process which has verified an ideal solution for wheel refurbishment.

Step 1: use sandblasting equipment or shot blasting equipment to strip old paints, or remove rusts, dirts, scratches, to obtain a clean, smooth and adhesive surface.

Step 2: use powder coating equipment to cover a durable, corrosion-resistant and decorative film.

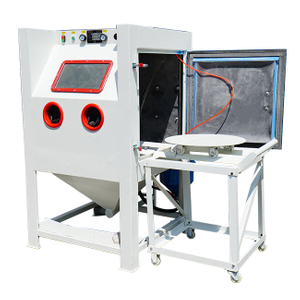

Pretreatment - Automatic Sandblasting Cabinet

This sandblasting machine is extremely popular for wheel finish among worldwide customers, as the full automatic operation reduces time and labor while ensures efficiency, quality consistency, and flexiblility

The 360 degree turntable rotates automatically while auto guns swinging and blasting that ensures all surfaces and corners can be cleaned uniformly.

Features

1.The blasting guns can be set both manual or automatic operation to meet your various needs.

2.Heavy-duty turntable is ideal to load large, irregular shaped workparts.

3.Blasting time can be set as required, the machine will automatically stop when time arrives.

4.Control panel at the front gives you easy access to set blasting mode as well as control the dust collector.

5.A dust removing system of the sandblasting machine ensures a clear working view, and the vented air is dustfree.

Specifications

Model: | KF-1212-4A |

Working chamber dimension(L*W*H): | 1200mm*1200mm*850mm |

Power supply: | 220V, 50HZ (voltage can be customized as local) |

Machine light power: | 220V, LED* 2 |

Compressed air source: | 5-7bar(kg/㎡) |

Air flow: | 0.8-3m3/min dry and clean compressed air |

Separator air volume: | 8.5m3/min |

Dust removal method | Cartridge Filter Type |

Blasting Gun Qty | 4 pcs |

Blasting Nozzle | Boron Carbide |

COLO-191S-V Electrostatic Powder Coating Machine

COLO-191S advanced system with intelligent functions requires you minimum efforts to handle challenging jobs, easy for beginners, powerful for specialists. This is a box feed type model which allows for quick color change, we also have hopper type for constant production of single color.

Features

1) The applied DVC technology allows you to precisely control crucial paramters such as high voltage, spraying current and powder outpur, achieving perfect and repeatable coating results.

2) One-touch intelligent buttons for quick change of different shapes, standing for 3 pre-set application programs for flat parts, corners and re-coating jobs, suitable for beginners quickly access to jobs.

3) Allows experienced users to create and store personalized 20 kinds of application programs optimized for your parts and powder. Each part can be coated always with its ideal settings.

COLO-S-2315 Manual Powder Spray Booth for Alloy Wheel

This powder booth provides a bright and clean environment for spraying process. Space-saving manual powder booth features easy and economical for powder application of small and medium-sized workpieces.

Features

1. High-precision filters effectively separate powders from airflow and ensures only particle-free air discharged to workshop

2. Filter cleaning is acted by pulse-jetting system, which extend filter life and increase powder recovery rate.

3. Powder-coated steel constructed booth is corrosion resistant for longer service life.

4. A removable powder hopper at booth bottom simplifies the utilization of recovery powders

5. A user-friendly PLC panel integrates all functions, such turning on / off fans, setting pulse-jetting time and interval, light on/off, emergency stop etc.

Specifications

| Model | COLO-S-2315

|

| Operating Dimensions | Width2300 * Depth1500 * Heght1500mm |

| Overall dimensions | Width2550 * Depth2100 * Heght2240mm |

Power Supply

| 220V/380V, 3Phase, 50-60HZ

|

Fan Power

| 4 kw

|

Filter Count

| 4 pcs, Quick-release Type

|

Filter Material

| Polyester

|

Filter Cleaning

| Pneumatic

|

Air Consumption

| 4000m^3/h

|

COLO-1515 Electric Powder Coating Oven for Alloy Wheel

Electric curing oven is simple and efficient for powder curing process with small batch jobs, ideal for alloy wheels, bike frames, motorcycle parts, etc.

Features

1. Electric heating method features easy operation, high efficiency and environment-friendly.

1. PLC control system provides a high-precision heating process which allows to set the required temperature and heating time accurately

3. The oven utilizes a sandwich panel design. Rockwool insulation of at least 100mm is inserted between galvanized inner wall and color-steel external skins, effectively minimums temperature dropping.

4. Built with loading frames and trolley could easily carrying batch workpieces in and out of the oven.

Specifications

| Model | COLO-1515 |

| Working dimensions | Width1500 x Height1500 x Depth1500 mm |

| Power supply electric | 18kw |

| Voltage | 380V/220V (Custom Voltage Available) |

| Frequency | 50-60hz |

| Warm-up time | 15-30 min. (180° C) |

| Temperature stability | < ± 3-5°C |

| Temperature max | 250° C |

| Ventilation performance | 805-1677m3/h |

| Motor power | 0.75kw |

| Transportation | Trolley |