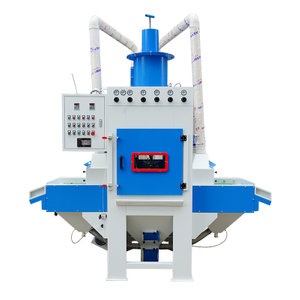

Automatic Sandblasting Machine for Paint Remove

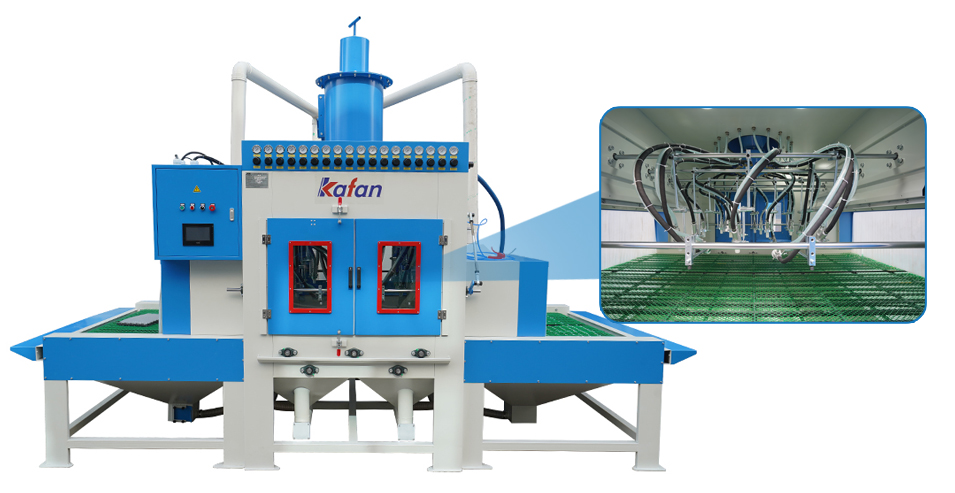

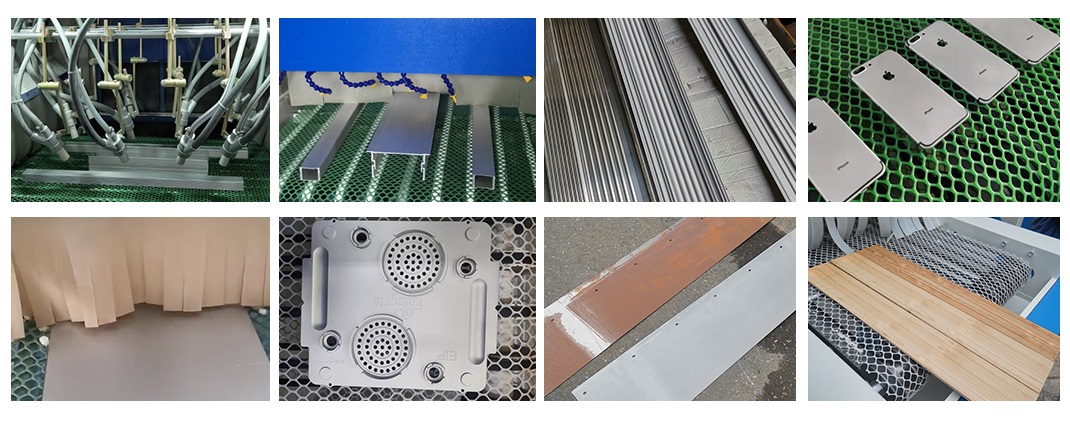

This conveyor type automatic blasting machine is widely applied to treatment of panel shaped parts, such as removing paint from wood boards, remove paint and rust from steel plates, roughing surface of aluminium plates.

Belt conveyor blasting machine allows a batch of workparts continuously pass thru the processing chamber for automatic media blasting, which ahieves high producrion and unifom processing quality.

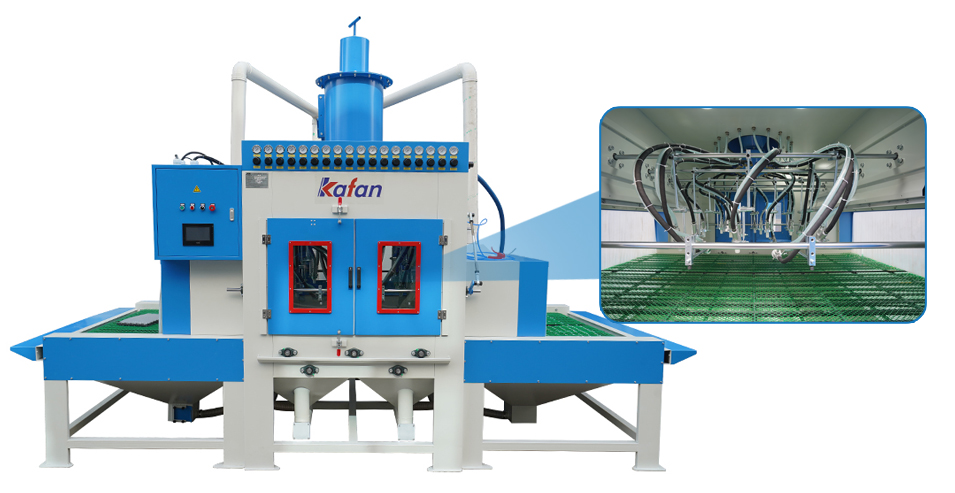

How automatic sandblasting machine works?

The operators put workparts on the conveyor belt, workparts are continuously transported into the sandblasting area, while the a group of blasting guns automatically swinging and blasting, ensures each workpart is entirely get blasted. Then the workparts pass through the clean room for dust cleaning, finally comes out from the other side of the conveyor to be discharged.

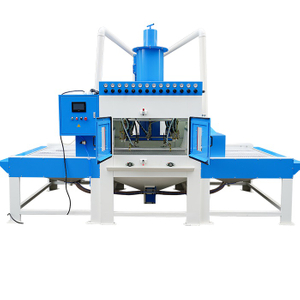

Automatic Conveyor Sandblasting Machine Features:

Automatic Blast Guns

Workparts are conveyed to the sandblasting area where they are processed by a group of automatic guns. Each blast gun is individually controlled for working by demands. Depending on the parts' shapes and dimensions, the automatic sandblast guns can be set for fixed blasting or oscillating blasting with adjustable angles. The gun nozzle is made of durable borron carbide material.

Continuous Conveyor Belt

The conveyor motor is controlled by frequency converter, whose speed can be steplessly regulated by inverter within the range of 0 ~ 2m/min. Several types of conveyor belt are available to move your parts through the blasting area, such as stainless steel belt, rubber belt, or roller conveyor. The rubber type belt is wear-resistant and corrosion resistant.

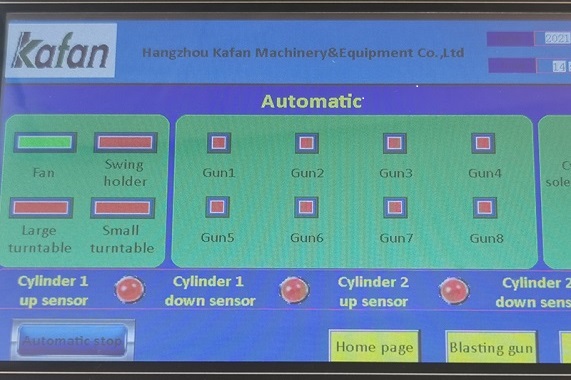

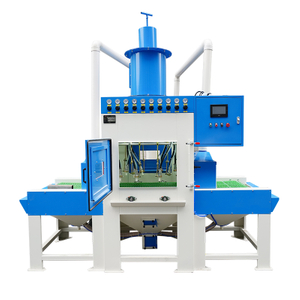

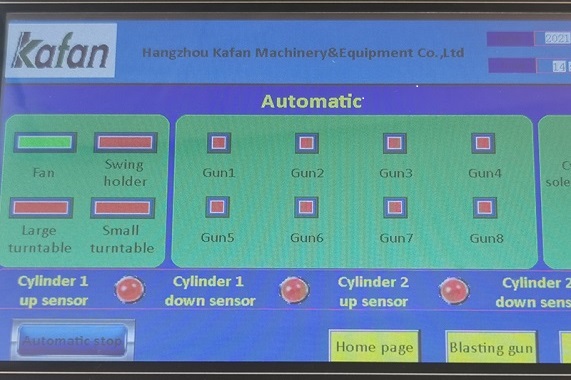

PLC Control with Touching Screen

The sandblaster applies advanced PLC electric control system, with a high degree of flexibility and stability. The touching screen offers user-friendly interface to manage the blast working, adjust conveyor speed or start the dust collector. High automation guarantees the balanced uniform blasting effect, as well as safe production

Dust Removing & Media Recycling

Designed with cyclone separator for effectively separation of abrasives from dusts. Along with an independent cartridge filter dust removal system with excellent effect of dust extraction and ventilation, Blast-removed dust particles are exhausted to the dust collector while blast media is collected at the bottom of the cabinet, then returned to the storage hopper for further use.

Automatic Comveyor Sandblasting Machine Specifications

| Model | KF-4615-20A |

| Working Size | 1500*1900*1000mm |

| Pass Thru Size | 1550*550mm |

| Overall Size | 4600*1900*2139mm |

Total Weight

| 1500kgs |

Total Power

| 7.8kw |

| Dust Collector Fan Motor | 7.5kw |

| Loading of Conveyor | 300kgs |

| Conveyor Speed | 0-5m/min, adjustable |

| Drive of Conveyor | 0.4kw speed adjustable |

| Gun Clamp | Automatic swing,

speed adjustable

Power 400W |

| Gun QTY | 20pcs |

| Compressed air Requirements | 35CFM/Per Gun 3-8bar(kg/cm2) |

| Conveyor Speed | 0-5m/min, adjustable |

| Body Material | Cold rolled steel plate |

*The dimension and blast gun quality and other parameters can be customized as requests.

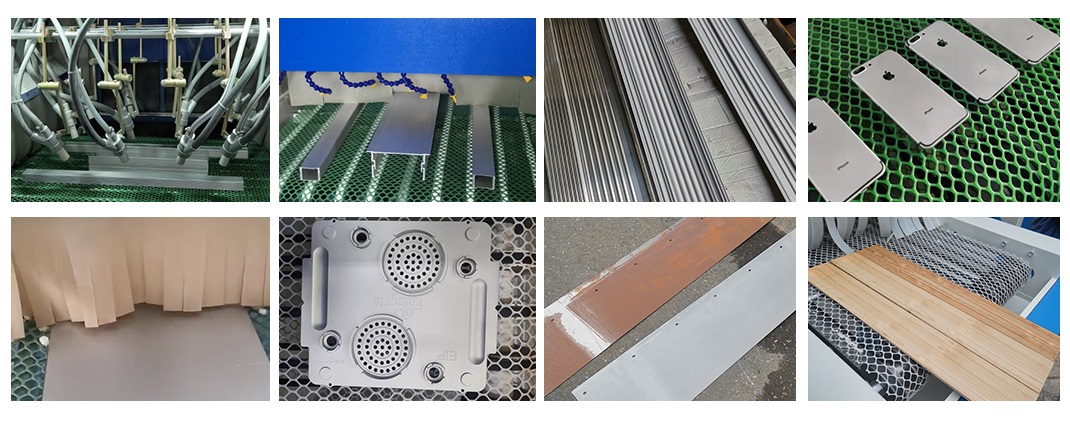

Automatic Conveyor Sandblasting Machine Applications

This automatic sandblaster is ideal for high-volume production of parts that cannot be subjected to part-on-part contact. recommended for processing flat shape workpieces like steel plate, glass plate, wood plates, plastic plates, aluminum plates or profiles, as well as pipe or tube shaped objects

Why Choose Kafan Automatic Sandblasting Systems?

1. High productivity and automation, reduced labor and time.

2. Batch processing increase quality consistency, avoids the uneven blasting effect, chromatic aberration and quality problem.

3. The blasting machine can be designed according to workparts of different sizes, different shapes and different finishing requirements.

4. Each sandblaster is made of durable steel materials with coated surface, and built with quality imported components, which maximize working performance.