Product: Automatic conveyor sandblasting machine

Product: Automatic conveyor sandblasting machine

Customer Location: small galvanized parts

Application: blasting aluminium plates

This automatic conveyor sandblasting machine is going to be shipped to one of our clients in India. They use this machine for processing hot dip galvanized parts. In their case after sandblasting, silicon rubber mounting will be done, thus bonding should be good between metal and silicon rubber.

How does the conveyor blast machine works?

In our pass through conveyor blasting machines, workparts are continuously presented to an array of pre-positioned guns, the certain quantity of suction-blast guns are bracketed to sweep parts in linear motion synchronized with continuous movement of the belt. As the parts are conveyed in and out of the blast chamber on an adjustable-speed rubber or steel mesh belt.

Automatic sand blasting machines allows batch processing of small workparts with excellent efficiency and consistent quality.

Automatic Blasting Chamber

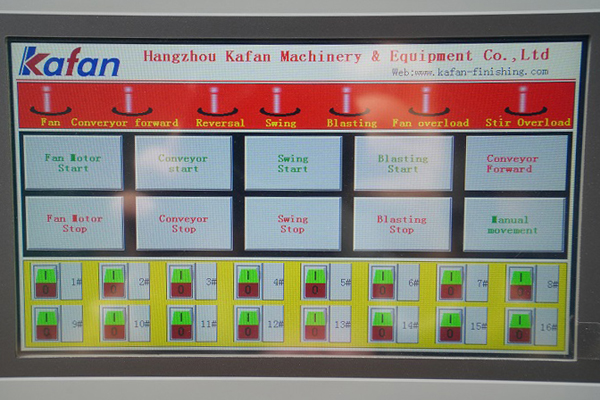

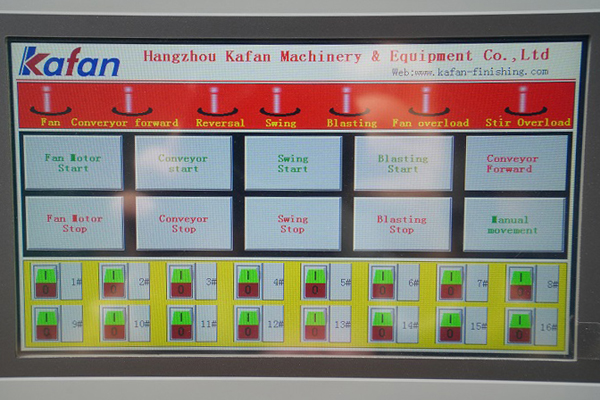

PLC Touch Control

Customer's Galvanized Parts

Automatic Conveyor Sand Blasting Machine Configurations & Features

Individual automatic control of each blasting gun, swing angle and distance to the workpiece are adjustable.

Drive of conveyor speed controllable with variable frequency 0-2m/min

Automatic abrasive reusable system

Thoroughly dust collect system leaves a clear working view and ensures the recycling of pure abrasive and the free dust air discharged to the atmosphere

Equip with safety operation interlock system by solenoid valve between suction system and blasting system to control air supply.

PLC control system with touch screen which can be connected to the phone or computer for remote control.

Adjustable height curtain at both ends to prevent the dust from escaping.

Automatic Comveyor Sandblasting Machine Specifications

| Model | KF-3208-10A |

| Working Size | 1100*1200*1000mm |

| Pass Thru Size | 800 X 300mm |

| Overall Size | 3200*1200*2139mm |

| Dust Collector Size | 1200*1300*2400mm |

Total Power

| 7.8kw |

| Dust Collector Fan Motor | 7.5kw |

| Conveyor Speed | 0-5m/min, adjustable |

| Drive of Conveyor | 0.4kw speed adjustable |

| Gun Clamp | Automatic swing,

speed adjustable

Power 400W |

| Gun QTY | 10pcs |

| Compressed air Requirements | 35CFM/Per Gun 3-8bar(kg/cm2) |

| Body Material | Cold rolled steel plate

|

Product: Automatic conveyor sandblasting machine

Product: Automatic conveyor sandblasting machine