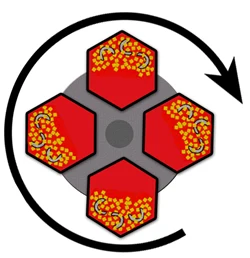

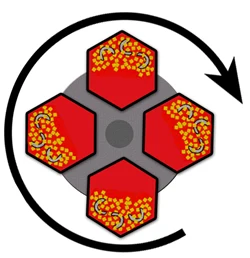

The centrifugal barrel finishing system is mounted with several tumbling barrels into a drum, like a ferris wheel. Each barrel is filled with workparts, finishing medias and compounds, approximately 50%-80% full of the container. The entire drum system revolves while each barrel rotates itself simultaneously, which produces centrifugal forces on media and parts making them rub and contact each other.

Such centrifugal force is extremely powerful thus it could remove sharp edges, heavy burrs, thick coatings and rust which vibratory or rotary finishing can not reach. Centrifugal barrel tumbler complete deburring, polishing, rediusing, cleaning process in fast time and superior effect.

Centrifugal Barrel Finishing Machine Application

Applicable for batch processing of metal and non-metal parts, etc. Such as apparel accessories, glasses accessories, watch and clock accessories, electronic accessories, hardware, machiney accessories in different shapes and hardness.

We supply different capacities of centrifugal barrel tumbler 15L, 30L, 40L, 60L, 80L

| Model | Capacity | Motor Power | Speed | Inner Lining | Weight | Size(L*W*H) |

| CL-15 | 2*7.5L | 1.1kw | 185r/min | 5-8mm | 200kg | 850*880*980mm |

| CL-30 | 4*7.5L | 1.5kw | 185r/min | 5-8mm | 350kg | 970*990*1175mm |

| CL-40 | 4*10L | 2.2kw | 165r/min | 6-10mm | 800kg | 1100*1000*1400mm |

| CL-60 | 4*15L | 5.5kw | 165r/min | 8-12mm | 1000kg | 1150*1100*1700 |

| CL-80 | 4*20L | 5.5kw | 145r/min | 8-12mm | 1200kg | 1300*1250*1815mm |