Automatic sandblasting machine is designed for big-volume processing of workparts with various sizes and shapes, mean while meet the requirement of consistent quality. kafan automatic sandblasting machines speeds up production time with using less manual efforts.

To suit for different applications, there are different types of automatic sandblasting machine. Whatever your process objectives are, Kafan's standard or custom-designed automation machine will achieve the highest surface preparation standards.

1. For big volume of extrenemly small and light parts - Automatic Tumble Basket Blast Machine

Automatic tumbling basket blast machine, also called rotary drum blaster, can process small parts in mass production, like screws, zippers, 3D printed parts, and so on.

Workpieces can be cleaned efficiently at higher speed due to abrasive blast stream exposure and mutual friction as they tumble in the tumbling basket. Parts will contact with each other inside the basket. If any tiny scratches on the parts are not acceptable, please ignore this method.

Automatic Tumble Blast Machine Working Process

-Load the parts into the basket.

-Set the timer as per request.

-The basket will tumble and the blast gun will work automatically.

-When time Arrive, the machine will stop automatically.

*Batch parts will be processed entirely and evenly through automatic blasting guns and tumbling drum. Optimal surface finishes can be achieved by varying media, tumbling speed, blast duration, blasting pressures, and media flow.

2. For batch medium-sized or heavier parts with complex shapes - Automatic Tumble Belt Blast Machine

Automatic tumbling belt blast machine will be applied for these parts for batch processing. Workpieces tumble on the rubber belt. Workpieces rotate at a low speed to provide an even exposure to the abrasive streams, so that they are exposed to the blasting abrasive on all surfaces.

Four or more nozzles blast all parts evenly to deliver a consistent finish automatically. Nozzles are mounted on an oscillating blast gun to ensure maximum coverage of all parts.

Tumble Belt Blast Machine Working Process

- Load parts on the rubber belt

- Set the timer according to required period

- The belt will tumble automatically and get perfectly finished parts.

-When time Arrive, the machine will stop automatically.

*Parts tumble on a thick, perforated rubber belt, a group of blast guns uniformly blast medias to all exposed surfaces to deliver a consistent finish automatically.

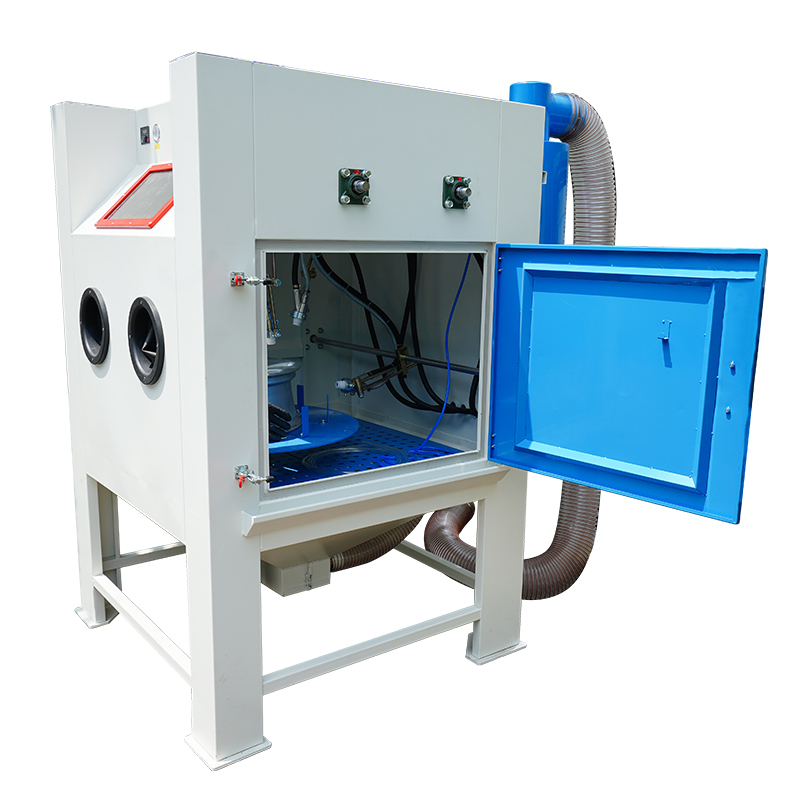

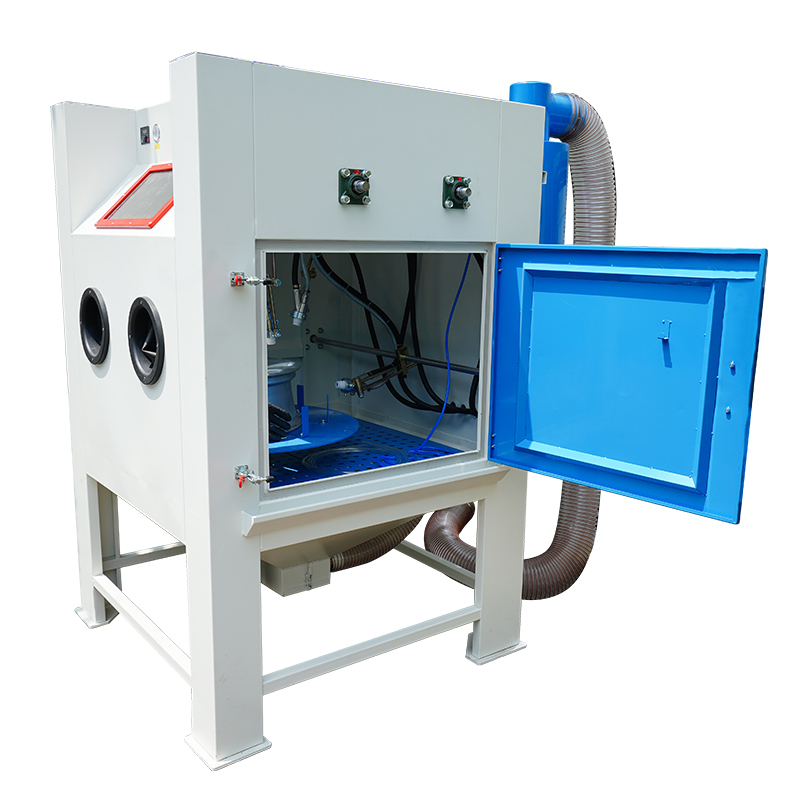

3. For big cylindrical or complex parts with blind spots - Automated Single Turntable Blasting Cabinet

Automated single turntable sandblasting cabinet is also known as rotary table sandblaster. It is designed to process a big complex shaped workpart each time, such as wheels, moulds.

Nozzles are mounted on a rotary head to provide optimal sand coverage on the parts surface.This machine is popular with clients due to its simple operating principle, lower cost and its flexibility.

Automatic Single Turntable Blast Machine Working Process:

- Mount the fixtures on the turntable if there are any.

- Load parts on the motorized turntable.

- Start the automatic blast gun and dust collector

-Unload the parts after predetermined cycle

*As a group of auto guns blasting and swinging, the turntable rotates automatically at the same time, thus all surfaces and corners of the object can be cleaned thoroughly and evenly.

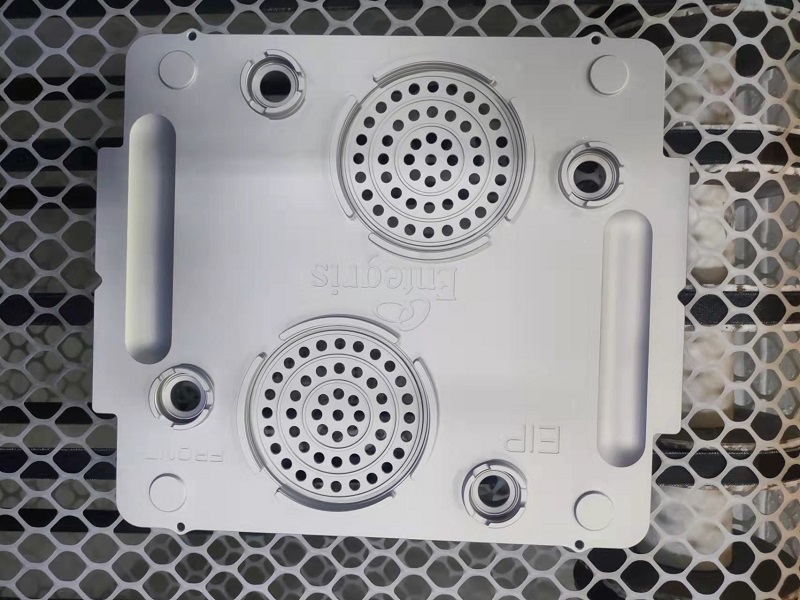

4. For small-to-medium cylinderical parts in batch production - Automated Indexing Turntables Blasting Machine

Indexing turntables automatic blasting system are specially designed to process a large batch of parts of complex shapes and sizes without touching each other continuously. It can increase the productivity of repetitive blasting parts.

It allows blasting parts getting an exact quality or design standard, production supervisors can be assured of every part on every shift being blasted in exactly the same way.

Indexing Turntable Automatic Blast Machine Working Process

- Load parts manually or robotically at the loading station.

- Leave the parts travel automatically inside the cabinet

- Unload the delicate finishing parts.

The automarc sandblasting machine is equipped with multi-independently rotating work stations on an indexing table that itself rotates through the cabinet, all in a satellite arrangement. There are four areas, loading-unloading area, waiting area, blasting area and blowing-off area

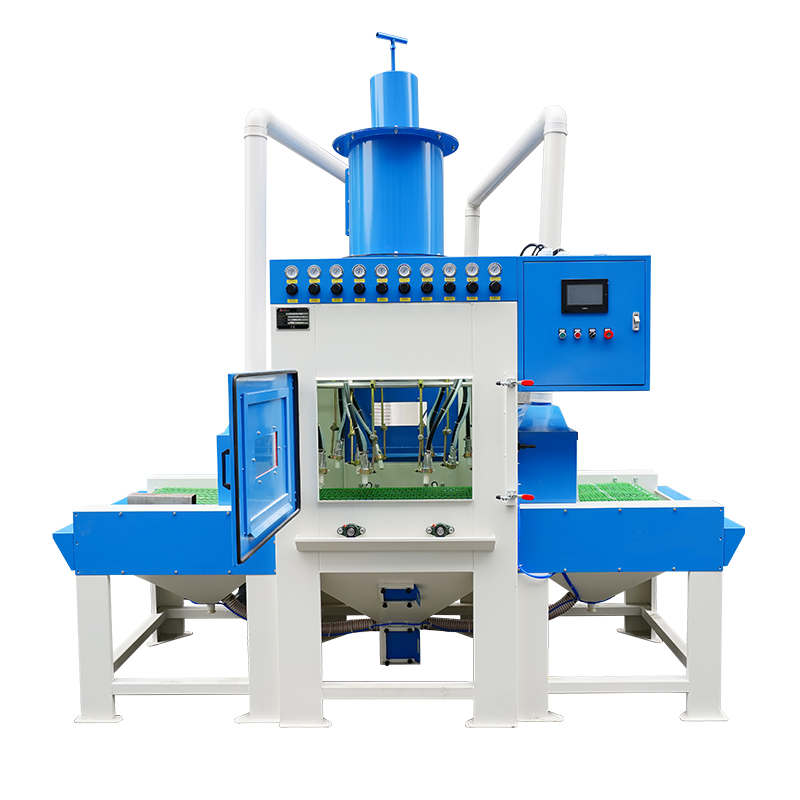

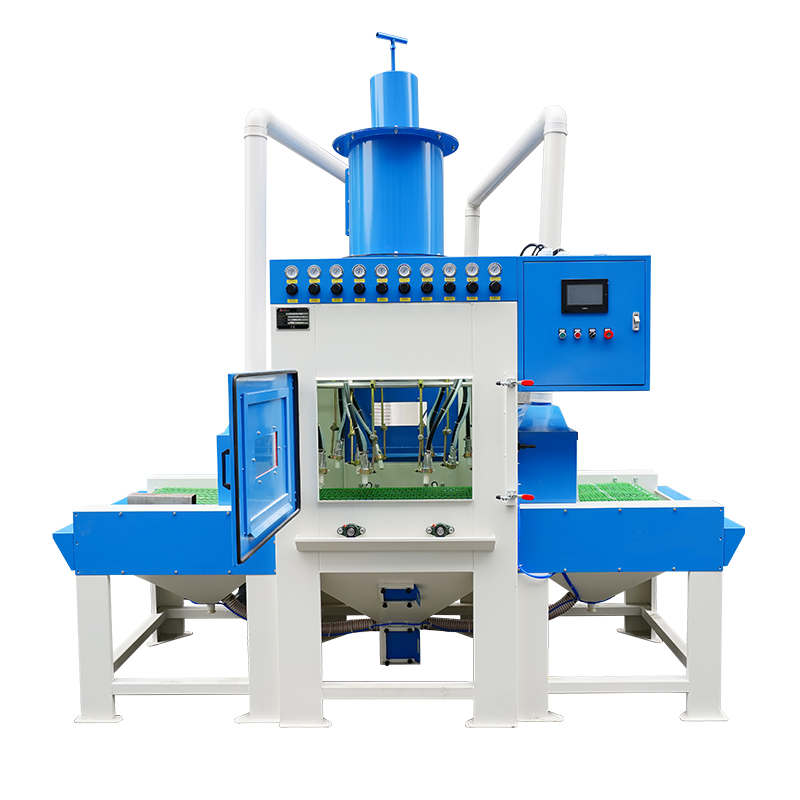

5. For small flat panels, large sheets, long-length profiles - Automatic Conveyor Sandblasting Machine

Automatic pass-through conveyor type sandblasting machine is also called in-line sandblasting system. It is ideal application for high-volume production of parts in various shapes and sizes. Such as, metal sheet, pipes, doors, frames, etc.

The blasting nozzles are designed to get the optimal performance and sufficient coverage of parts surface on the top or side. The conveyor belt running speed can be adjustable to meet different output. Machine sizes varies for different sizes of parts.

Automatic Conveyor Blast Machine Working Process

- Load parts on the belt manually or automatically by robotic arm.

- Set the blast gun fixed blasting or swinging blasting.

- Parts travel to the working cabinet and blasted by oscillating nozzles.

- Collect finished parts the at the exit.

The operators put or fix the workpiece on the conveyor belt, when the workpiece is transported into the sandblasting chamber, the blasting guns automatically swinging and blasting, ensures the products is blasted entirely.